Abstract

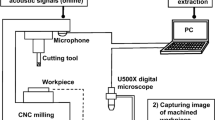

An artificial-neural-networks-based in-process tool wear prediction (ANN-ITWP) system has been proposed and evaluated in this study. A total of 100 experimental data have been received for training through a back-propagation ANN model. The input variables for the proposed ANN-ITWP system were feed rate, depth of cut from the cutting parameters, and the average peak force in the y-direction collected online using a dynamometer. After the proposed ANN-ITWP system had been established, nine experimental testing cuts were conducted to evaluate the performance of the system. From the test results, it was evident that the system could predict the tool wear online with an average error of ±0.037 mm. Experiments have shown that the ANN-ITWP system is able to detect tool wear in 3-insert milling operations online, approaching a real-time basis .

Similar content being viewed by others

References

DeGrarmo EP, Black JT, Kohser RA (1999) Materials and processes in manufacturing, 8th edn. Wiley, New York

Dutta RK, Kiran G, Paul S (2000) Assessment of machining features for tool condition monitoring in face milling using an artificial neural network. Proceedings of the Institution of Mechanical Engineers, Part B: J Eng Manuf 214(7):535–546

Wong YS, Yuen WK, Lee KS (1998) Machine vision monitoring of tool wear. Proc SPIE, vol 3518, Sensors and Controls for Intelligent Machining, Agile Manuf Mech, pp 17–24

Lin SC, Yang RJ (1995) Force-based model for tool wear monitoring in face milling. Int J Mach Tools Manuf 35(9)1201–1211

Lin SC, Lin RJ (1996) Tool wear monitoring in face milling using force signals. Wear 198(1-2):136–142

Wilcox SJ, Reuben RL, Souquet P (1997) Use of cutting force and acoustic emission signals for the monitoring of tool insert geometry during rough face milling. Int J Mach Tools Manuf 37(4):481–494

Choudhury SK, Rath S (2000) In-process tool wear estimation in milling using cutting force model. J Mater Process Technol 99(1):113–119

Tansel IN, Bao WY, Arkan TT (1999) Wear estimation in micro-end-milling with wavelet transformations and probabilistic neural networks. Intelligent engineering systems through artificial neural networks. Proceedings of the 1998 Artificial Networks in Engineering Conference, pp 755–760

Chen J (2003) Development of in-process tool wear prediction systems in end milling operations with dynamometer. Dissertation, Iowa State University

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Chen, J. An artificial-neural-networks-based in-process tool wear prediction system in milling operations. Int J Adv Manuf Technol 25, 427–434 (2005). https://doi.org/10.1007/s00170-003-1848-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1848-y