Abstract

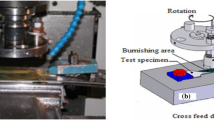

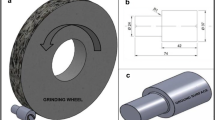

The aim of this study is to analyse the evolution of surface roughness finished by burnishing. Burnishing is done on a surface that was initially turned or turned and then ground.

It has been noted that burnishing an AISI 1042 steel offers the best surface quality when using a small feed value. This finishing process improves roughness and introduces compressive residual stresses in the machined surface. So, it can replace grinding in the machining range of the piece.

Also, an analytical model has been defined to determine the R t factor in relation to the feed. Good correlations have been found between the experimental and analytical results.

Similar content being viewed by others

References

Hassan AM (1997) An investigation into surface characteristics of burnished cast Al-Cu alloys. Int J Mach Tools Manuf 37:813

Bouzid Saï W, Lebrun JL (2003) Influence of finishing by burnishing on surface characteristics. JMEPEG 12:37–40

Ramarishna Rao PK, Shunmugam MS (1987) Investigations into surface topography, microhardness and residual stress in boring trepanning association machining. Wear 119:89

Zhang GM , Kapoor SG (1991) Dynamic of machined surface, part 2: construction of surface topography. J Eng Ind 113:145

Katayama S, Imai T (1990) Effect of tool materials on surface machined roughness and cutting force of low carbon resulfurized free machining steels. ISIJ Int 30:331

Wu DW, Matsumoto Y (1990) The effect of hardness on residual stresses in orthogonal machining of AISI 4340 steel. J Eng Ind 112(1990):245

Bouzid Saï W, Ben Salah N, Lebrun JL (2001) Influence of machining by finishing milling on surface characteristics. Int J Mach Tools Manuf 41:443–450

Macherauch E, Hauk V (1986) Residual stresses in science and technology. International conference on residual stresses, Garnisch, Patenkirchen

Liu CR, Barash MM (1982) Variables governing patterns of mechanical residual stress in a machined surface. J Eng Ind 104:257

Scholtes B (1987) Residual stresses introduced by machining. J Adv Surf Treat 4:59

M’Saoubi R, Outeiro JC, Changeux B, Lebrun JL, Morao Dias A (1999) Residual stress analysis in orthogonal machining of standard and resulfurized AISI 316 L steels. Int J Mater Process Tech 96:225

Dixit US, Dixit PM (1997) A study of residual stresses in rolling. Int J Mach Tools Manuf 37:832

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Acknowledgments

Thanks are due to Dr JL. Lebrun, from the Ecole Nationale Supérieure des Arts et Métiers d’Angers, France for his assistance in residual stresses measuring.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouzid, W., Tsoumarev, O. & Saï, K. An investigation of surface roughness of burnished AISI 1042 steel. Int J Adv Manuf Technol 24, 120–125 (2004). https://doi.org/10.1007/s00170-003-1761-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1761-4