Abstract

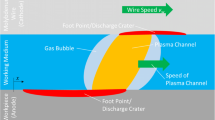

In this study, the effect of the cutting parameters on size of erosion craters (diameter and depth) on wire electrode were experimentally and theoretically investigated in wire electrical discharge machining (WEDM). The experiments were conducted under the different cutting parameters of pulse duration (300, 500, 700, and 900 ns), open circuit voltage (80, 100, and 270 V), wire speed (5, 8, and 12.5 m min -1 ) and dielectric flushing pressure (6, 12, and 18 kg cm -2 ). Brass wire of 0.25 mm diameter and AISI 4140 steel of 0.28 mm thickness were used as tool and workpiece materials in the experiments. It is found that increasing the pulse duration, open circuit voltage, and wire speed increases the crater size, whereas increasing the dielectric flushing pressure decreases the crater size. The variation of wire crater size with machining parameters is modelled mathematically by using a power function. The level of importance of the machining parameters on the wire crater size is determined by using analysis of variance (ANOVA).

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tosun, N., Pihtili, H. The Effect of Cutting Parameters on Wire Crater Sizes in Wire EDM . Int. Journ. Adv. Manufac. Tech. 21, 857–865 (2003). https://doi.org/10.1007/s00170-002-1404-1

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1404-1