Abstract

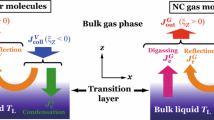

The employment of different mathematical models to address specifically for the bubble nucleation rates of water vapour and dissolved air molecules is essential as the physics for them to form bubble nuclei is different. The available methods to calculate bubble nucleation rate in binary mixture such as density functional theory are complicated to be coupled along with computational fluid dynamics (CFD) approach. In addition, effect of dissolved gas concentration was neglected in most study for the prediction of bubble nucleation rates. The most probable bubble nucleation rate for the water vapour and dissolved air mixture in a 2D quasi-stable flow across a cavitating nozzle in current work was estimated via the statistical mean of all possible bubble nucleation rates of the mixture (different mole fractions of water vapour and dissolved air) and the corresponding number of molecules in critical cluster. Theoretically, the bubble nucleation rate is greatly dependent on components’ mole fraction in a critical cluster. Hence, the dissolved gas concentration effect was included in current work. Besides, the possible bubble nucleation rates were predicted based on the calculated number of molecules required to form a critical cluster. The estimation of components’ mole fraction in critical cluster for water vapour and dissolved air mixture was obtained by coupling the enhanced classical nucleation theory and CFD approach. In addition, the distribution of bubble nuclei of water vapour and dissolved air mixture could be predicted via the utilisation of population balance model.

Similar content being viewed by others

Abbreviations

- C :

-

Correction factor

- D :

-

Rate of molecules striking on a surface area of the cluster (molecules/m2s)

- f L :

-

Lost degree of freedom during the dissolution process

- G(V):

-

Growth rate of bubble number density (number/m3s)

- ΔH vap :

-

Enthalpies for the evaporation of the solution

- ΔH f :

-

Enthalpies for the freezing of the solution

- J :

-

Bubble nucleation rate (nuclei/m3s)

- k B :

-

Boltzmann’s constant (J/K)

- k :

-

Specified number of moments

- Li:

-

Abscissas

- m k :

-

kth moment of number density function

- m :

-

Mass of molecule (kg)

- n c :

-

Number of molecules

- N:

-

Number density of the liquid (molecules/m3)

- n(V,t):

-

Bubble number density distribution per unit volume (V) for a given time (t)

- P :

-

Pressure (Pa)

- P i :

-

Pressure to saturate the dissolved gas in the liquid

- Q :

-

Order of quadrature approximation

- r :

-

Radius (m)

- R :

-

Gas constant (J/K mol)

- x :

-

Mole fraction of dissolved gas molecules in the solution

- T :

-

Liquid temperature (K)

- T f :

-

Melting temperature of the solution (K)

- v :

-

Volume of a molecules (m)

- wi:

-

Weights

- Z f :

-

Zeldovich nonequilibrium factor

- β′ :

-

Accommodation coefficient of molecules to the cluster

- ξ :

-

Fraction of vapour or gas molecules in the critical cluster

- η :

-

Weight factor of the vapour and dissolved gas molecules for the formation of critical cluster

- λ :

-

Rate of number of gas molecules participated in the formation of critical cluster per unit volume (molecules/m 3 s)

- ρ :

-

Density (kg/m3)

- g :

-

Gas

- H2O:

-

Water

- l :

-

Liquid water

- v :

-

Vapour

- gv :

-

Vapour and Gas

References

Arndt R.E.A.: Cavitation in fluid machinery and hydraulic structures. Annu. Rev. Fluid Mech. 13(1), 273–326 (1981). doi:10.1146/annurev.fl.13.010181.001421

Elias E., Chambré P.L.: Bubble transport in flashing flow. Int. J. Multiph. Flow 26(2), 191–206 (2000). doi:10.1016/S0301-9322(99)00011-7

Kierzkowska-Pawlak H., Chacuk A.: Pressure swing absorption of carbon dioxide in physical solvents, vol. 35. Environmental Engineering III. Taylor & Francis Group, London (2009)

Sampath Kumar K., Moholkar V.S.: Conceptual design of a novel hydrodynamic cavitation reactor. Chem. Eng. Sci. 62(10), 2698–2711 (2007). doi:10.1016/j.ces.2007.02.010

Polanco G., Holdø A.E., Munday G.: General review of flashing jet studies. J. Hazard Mater. 173(1–3), 2–18 (2010). doi:10.1016/j.jhazmat.2009.08.138

Lubetkin S.D.: The fundamentals of bubble evolution. Chem. Soc. Rev. 24(4), 243–250 (1995)

Lubetkin, S.D.: Why is it much easier to nucleate gas bubbles than theory predicts? Langmuir 19(7), 2575–2587 (2003). doi:10.1021/la0266381

Caupin F., Herbert E.: Cavitation in water: a review. Comptes Rendus Physique 7(9–10), 1000–1017 (2006). doi:10.1016/j.crhy.2006.10.015

Delale C.F., Hruby J., Marsik F.: Homogeneous bubble nucleation in liquids: the classical theory revisited. J. Chem. Phys. 118(2), 792–806 (2003)

Delale C.F., Okita K., Matsumoto Y.: Steady-state cavitating nozzle flows with nucleation. J. Fluids Eng. 127(4), 770–777 (2005)

Holden B.S., Katz J.L.: The homogeneous nucleation of bubbles in superheated binary liquid mixtures. AIChE J. 24(2), 260–267 (1978). doi:10.1002/aic.690240215

Singhal A.K., Athavale M.M., Li H., Jiang Y.: Mathematical basis and validation of the full cavitation model. J. Fluids Eng. 124(3), 617–624 (2002)

Kwak H.-Y., Oh S.-D.: Gas-vapor bubble nucleation-a unified approach. J. Colloid Interface Sci. 278(2), 436–446 (2004)

Huang B., Zhao Y., Wang G.: Large eddy simulation of turbulent vortex-cavitation interactions in transient sheet/cloud cavitating flows. Comput. Fluids 92(0), 113–124 (2014). doi:10.1016/j.compfluid.2013.12.024

Dai, S., Younis, B.A., Sun, L.: Large-eddy simulations of cavitation in a square surface cavity. Appl. Math. Model. doi:10.1016/j.apm.2014.04.059

Goncalvès E.: Modeling for non isothermal cavitation using 4-equation models. Int. J. Heat Mass Transf. 76(0), 247–262 (2014). doi:10.1016/j.ijheatmasstransfer.2014.04.065

Sou A., Biçer B., Tomiyama A.: Numerical simulation of incipient cavitation flow in a nozzle of fuel injector. Comput. Fluids 103(0), 42–48 (2014). doi:10.1016/j.compfluid.2014.07.011

Rodio M.G., Congedo P.M.: Robust analysis of cavitating flows in the Venturi tube. Eur. J. Mech. B/Fluids 44(0), 88–99 (2014). doi:10.1016/j.euromechflu.2013.11.002

Perpar M., Polutnik E., Pečar M., Žun I.: Bubbly structures in a cavitating slot orifice. Exp. Therm. Fluid Sci. 53(0), 57–69 (2014). doi:10.1016/j.expthermflusci.2013.11.003

Hao Z.R., Gu C.W.: Numerical modeling for gaseous cavitation of oil film and non-equilibrium dissolution effects in thrust bearings. Tribol. Int. 78(0), 14–26 (2014). doi:10.1016/j.triboint.2014.04.028

Bastos F., de Freitas R.: Modeling gaseous and vaporous cavitation in liquid flows within the context of the thermodynamics of irreversible processes. Int. J. Non-Linear Mech. 65(0), 245–252 (2014). doi:10.1016/j.ijnonlinmec.2014.06.006

Kwak H.-Y., Kang K.-M.: Gaseous bubble nucleation under shear flow. Int. J. Heat Mass Transf. 52(21–22), 4929–4937 (2009). doi:10.1016/j.ijheatmasstransfer.2009.06.002

Cheng J., Yang C., Mao Z.-S., Zhao C.: CFD modeling of nucleation, growth, aggregation, and breakage in continuous precipitation of barium sulfate in a stirred tank. Ind. Eng. Chem. Res. 48(15), 6992–7003 (2009). doi:10.1021/ie9004282

McGraw R.: Description of aerosol dynamics by the quadrature method of moments. Aerosol Sci. Technol. 27(2), 255–265 (1997). doi:10.1080/02786829708965471

Petitti M., Vanni M., Marchisio D.L., Buffo A., Podenzani F.: Simulation of coalescence, break-up and mass transfer in a gas–liquid stirred tank with CQMOM. Chem. Eng. J. 228(0), 1182–1194 (2013). doi:10.1016/j.cej.2013.05.047

Venneker B.C.H., Derksen J.J., Vanden Akker H.E.A.: Population balance modeling of aerated stirred vessels based on CFD. AIChE J. 48(4), 673–685 (2002). doi:10.1002/aic.690480404

Gunawan R., Fusman I., Braatz R.D.: High resolution algorithms for multidimensional population balance equations. AIChE J. 50(11), 2738–2749 (2004). doi:10.1002/aic.10228

Wang Y.-C., Brennen C.E.: One-dimensional bubbly cavitating flows through a converging-diverging nozzle. J. Fluids Eng. 120(1), 166–170 (1988). doi:10.1115/1.2819642

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Hong, B.Z., Keong, L.K. & Shariff, A.M. CFD modelling of most probable bubble nucleation rate from binary mixture with estimation of components’ mole fraction in critical cluster. Continuum Mech. Thermodyn. 28, 655–668 (2016). https://doi.org/10.1007/s00161-014-0398-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-014-0398-x