Abstract

In this article, we demonstrate the state-of-the-art of multi-scale topology optimization for 3D structural design. Many structures designed for additive manufacturing consist of a solid shell surrounding repeated microstructures, so-called infill material. We demonstrate the performance of different types of infill microstructures, such as isotropic truss or plate lattice structures and show that the best results can be obtained using spatially varying and oriented orthotropic microstructures. Furthermore, we demonstrate how implicit geometry modeling using nTop platform can help to interpret these multi-scale designs as single-scale manufacturable designs (de-homogenization). More importantly, we demonstrate the small difference in performance between these multi-scale and single-scale designs through extensive numerical testing. The presented method is at least 3 orders of magnitude more efficient compared to standard density-based topology optimization, allowing for high-resolution 3D structures to be obtained on a standard workstation PC.

Similar content being viewed by others

References

Aage N, Andreassen E, Lazarov BS, Sigmund O (2017) Giga-voxel computational morphogenesis for structural design. Nature 550(7674):84–86

Alexandersen J, Lazarov BS (2015) Topology optimisation of manufacturable microstructural details without length scale separation using a spectral coarse basis preconditioner. Comput Methods Appl Mech Eng 290:156–182

Allaire G, Aubry S (1999) On optimal microstructures for a plane shape optimization problem. Struct Optim 17(2):86–94

Allaire G (2002) Shape optimization by the homogenization method. Springer, New York

Amir O, Aage N, Lazarov BS (2013) On multigrid-cg for efficient topology optimization. Struct Multidiscip Optim 49(5):815–829

Andersen MN, Wang F, Sigmund O (2021) On the competition for ultimately stiff and strong architected materials. Materials&design(198). https://doi.org/10.1016/j.matdes.2020.109356

Ansys Inc (2020) Ansys mechanical. https://www.ansys.com/products/structures

Autodesk Inc (2020) Autodesk fusion 360®;. https://www.autodesk.com/products/fusion-360/overview

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bendsøe MP, Sigmund O (2004) Topology optimization-theory, methods, and applications. Springer, Berlin

Bensoussan A, Lions J-L, Papanicolaou G (1978) Asymptotic analysis for periodic structures (studies in mathematics and its applications). Elsevier Science Ltd

Bourdin B (2001) Filters in topology optimization. Int J Numer Methods Eng 50(9):2143–2158

Brackett D, Ashcroft I, Hague R (2011) Topology optimization for additive manufacturing. 22nd Annual International Solid Freeform Fabrication Symposium - An Additive Manufacturing Conference, SFF 2011, pp 348–362

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190(26–27):3443–3459

Christensen RM (1986) Mechanics of low density materials. J Mech Phys Solids 34(6):563–578

Clausen A, Aage N, Sigmund O (2015) Topology optimization of coated structures and material interface problems. Comput Methods Appl Mech Eng 290:524–541

Clausen A, Aage N, Sigmund O (2016) Exploiting additive manufacturing infill in topology optimization for improved buckling load. Engineering 2(2):250–257

Coelho PG, Amiano LD, Guedes JM, Rodrigues HC (2016) Scale-size effects analysis of optimal periodic material microstructures designed by the inverse homogenization method. Comput Struct 174:21–32

COMSOL Inc (2019) Comsol multiphysics®;5.5. https://www.comsol.com

Cook RD, Malkus DS, Plesha ME (2001) Concepts and applications of finite element analysis. Wiley

Cramer AD, Challis VJ, Roberts AP (2015) Microstructure interpolation for macroscopic design. Struct Multidiscip Optim 53(3):489–500

Dassault Systèmes (2020) 3dexperience release r2021x. https://www.3ds.com/products-services/simulia/products/3dexperience

Du Z, Zhou X, Picelli R, Kim H (2018) Connecting microstructures for multiscale topology optimization with connectivity index constraints. ASME: J Mech Des 140(11):1–12

Francfort GA, Murat F (1986) Homogenization and optimal bounds in linear elasticity. Arch Ration Mech Anal 94(4):307–334

Fu J, Li H, Gao L, Xiao M (2019) Design of shell-infill structures by a multiscale level set topology optimization method. Comput Struct 212:162–172

Garner E, Kolken HMA, Wang CCL, Zadpoor AA, Wu J (2019) Compatibility in microstructural optimization for additive manufacturing. Add Manuf 26:65–75. https://doi.org/10.1016/j.addma.2018.12.007

Geoffroy-Donders P (2018) Homogenization method for topology optimization of structures built with lattice materials. Theses, Ecole Polytechnique

Geoffroy-Donders P, Allaire G, Michailidis G, Pantz O (2020a) Coupled optimization of macroscopic structures and lattice infill. Int J Numer Methods Eng

Geoffroy-Donders P, Allaire G, Pantz O (2020b) 3-d topology optimization of modulated and oriented periodic microstructures by the homogenization method. J Comput Phys 401:108994

Gibiansky LV, Cherkaev AV (1997) Microstructures of composites of extremal rigidity and exact estimates of the associated energy density. Report 1115, Ioffe Physico-Technical Institute, Acad of Sc, USSR, Leningrad, USSR, english translation. In: Cherkaev A.V, Kohn R.V (eds) Topics in the mathematical modelling of composite materials. Birkhäuser, Boston

Groen JP, Sigmund O (2018) Homogenization-based topology optimization for high-resolution manufacturable microstructures. Int J Numer Methods Eng 113(8):1148–1163

Groen JP, Stutz FC, Aage N, Bærentzen JA, Sigmund O (2020) De-homogenization of optimal multi-scale 3d topologies. Comput Methods Appl Mech Eng 364:112979

Groen JP, Wu J, Sigmund O (2019a) Homogenization-based stiffness optimization and projection of 2d coated structures with orthotropic infill. Comput Methods Appl Mech Eng 349:722– 742

Groen JP (2019b) Multi-scale design methods for topology optimization. Ph.D. Thesis, DTU Mechanical Engineering

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11(2):127–140

Hill R (1952) The elastic behaviour of a crystalline aggregate. Proc Phys Soc Sect A 65(5):349

Hollister SJ, Kikuchi N (1992) A comparison of homogenization and standard mechanics analyses for periodic porous composites. Comput Mech 10(2):73–95

Hu Y, Zhou Q, Gao X, Jacobson A, Zorin D, Panozzo D (2018) Tetrahedral meshing in the wild. ACM Trans Graph 37(4):1–14

Hu Y, Schneider T, Wang B, Zorin D, Panozzo D (2019) Fast tetrahedral meshing in the wild

Huang X, Zhou SW, Xie YM, Li Q (2013) Topology optimization of microstructures of cellular materials and composites for macrostructures. Comput Mater Sci 67:397–407

Jacobson A, Panozzo D, et al. (2018) libigl: A simple C++ geometry processing library. https://libigl.github.io/

Jiang L, Guo Y, Chen S, Wei P, Lei N, Gu XD (2019) Concurrent optimization of structural topology and infill properties with a CBF-based level set method. Front Mech Eng 14(2):171–189

Jiang L, Gu XD, Chen S (2020) Generative design of bionic structures via concurrent multiscale topology optimization and conformal geometry method. J Mech Des 143(1)

Kohn RV, Strang G (1986) Optimal design and relaxation of variational problems, i. Commun Pur Appl Math 39(1):113–137

Kumar T, Suresh K (2019) A density-and-strain-based k-clustering approach to microstructural topology optimization. Struct Multidiscip Optim 61(4):1399–1415

Liu L, Yan J, Cheng G (2008) Optimum structure with homogeneous optimum truss-like material. Comput Struct 86(13):1417–1425. Structural Optimization

Liu C, Du Z, Zhang W, Zhu Y, Guo X (2017) Additive manufacturing-oriented design of graded lattice structures through explicit topology optimization. J Appl Mech 84(8)

Liu J, Gaynor AT, Chen S, Kang Z, Suresh K, Takezawa A, Li L, Kato J, Tang J, Wang CCL, Cheng L, Liang X, To AC (2018) Current and future trends in topology optimization for additive manufacturing. Struct Multidiscip Optim 57(6):2457–2483

Luo Y, Li Q, Liu S (2019) A projection-based method for topology optimization of structures with graded surfaces. Int J Numer Methods Eng 118(11):654–677

Lurie KA, Cherkaev AV (1984) G-closure of a set of anisotropically conducting media in the two-dimensional case. J Optim Theory Appl 42(2):283–304

Milton GW (1986) Modelling the properties of composites by laminates. In: Ericksen JL, Kinderlehrer D, Kohn R, Lions J-L (eds) Homogenization and Effective Moduli of Materials and Media. Springer, New York, pp 150–174

Norris AN (1985) A differential scheme for the effective moduli of composites. Mech Mater 4(1):1–16

nTopology Inc (2020) ntop platform®;2.xx. https://ntopology.com

Pantz O, Trabelsi K (2008) A post-treatment of the homogenization method for shape optimization. SIAM J Control Optim 47(3):1380–1398

Pecullan S, Gibiansky LV, Torquato S (1999) Scale effects on the elastic behavior of periodic andhierarchical two-dimensional composites. J. Mech. Phys. Solids 47(7):1509–1542

Ranganathan SI, Ostoja-Starzewski M (2008) Universal elastic anisotropy index. Phys Rev Lett 101(5)

Rodrigues H, Guedes JM, Bendsøe MP (2002) Hierarchical optimization of material and structure. Struct Multidiscip Optim 24(1):1–10

Sigmund O (1994) Materials with prescribed constitutive parameters: An inverse homogenization problem. Int J Solids Struct 31(17):2313–2329

Sivapuram R, Dunning PD, Kim HA (2016) Simultaneous material and structural optimization by multiscale topology optimization. Struct Multidiscip Optim 54(5):1267–1281

Svanberg K (1987) The method of moving asymptotes–a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Träff E, Sigmund O, Groen JP (2019) Simple single-scale microstructures based on optimal rank-3 laminates. Struct Multidiscip Optim 59(4):1021–1031

Vermaak N, Michailidis G, Parry G, Estevez R, Allaire G, Bréchet Y (2014) Material interface effects on the topology optimization of multi-phase structures using a level set method. Struct Multidiscip Optim 50(4):623–644

Wang Y, Chen F, Wang MY (2017) Concurrent design with connectable graded microstructures. Comput Methods Appl Mech Eng 317:84–101

Wang Y, Kang Z (2018) A level set method for shape and topology optimization of coated structures. Comput Methods Appl Mech Eng 329:553–574

Wang Y, Groen JP, Sigmund O (2019a) Simple optimal lattice structures for arbitrary loadings. Extreme Mech Lett 29:100447

Wang Y, Sigmund O (2019b) Quasiperiodic mechanical metamaterials with extreme isotropic stiffness. Extreme Mech Lett:100596

Wu J, Clausen A, Sigmund O (2017) Minimum compliance topology optimization of shell-infill composites for additive manufacturing. Comput Methods Appl Mech Eng 326:358– 375

Wu J, Wang W, Gao X (2019) Design and optimization of conforming lattice structures. IEEE Trans Vis Comput Graph:1–1

Xue D, Zhu Y, Guo X (2020) Generation of smoothly-varying infill configurations from a continuous menu of cell patterns and the asymptotic analysis of its mechanical behaviour. Comput Methods Appl Mech Eng 366:113037

Zhang W, Sun S (2006) Scale-related topology optimization of cellular materials and structures. Int J Numer Methods Eng 68(9):993–1011

Zhou S, Li Q (2008) Design of graded two-phase microstructures for tailored elasticity gradients. J Mater Sci 43(15):5157– 5167

Zuo ZH, Huang X, Yang X, Rong JH, Xie YM (2013) Comparing optimal material microstructures with optimal periodic structures. Comput Mater Sci 69:137–147

Acknowledgements

The first author is indebted to Yiqiang Wang and the simulation team at nTopology inc. for valuable discussions during the preparation of this manuscript. Finally, the authors would like to thank Krister Svanberg for providing the MATLAB MMA code.

Funding

This work received support from the Villum Fonden through the Villum investigator project InnoTop and the support of nTopology inc.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

Our work relies on several methodologies implemented in either MATLAB or nTop platform. Specifically, the homogenization-based topology optimization has been performed in MATLAB, the methodology to do so has been discussed in detail in Groen et al. (2019b, 2020) and the reader is referred to these works for more details. The numerical homogenization, de-homogenization, meshing and fine-scale analysis have been performed using nTop platform (nTopology Inc 2020), details about this software platform can be found on https://support.ntopology.com/hc/en-us.

Additional information

Responsible Editor: Xu Guo

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

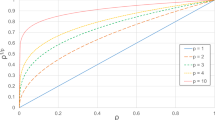

Appendix 1. Universal isotropy index

The universal isotropy index MU is obtained as (Ranganathan and Ostoja-Starzewski 2008),

here the superscripts V and R indicate the Voigt and Reuss measurements of the shear modulus G and bulk modulus K. These measurements can be obtained as (Hill 1952),

with compliance tensor S = E− 1 and,

Appendix 2. Mapping functions ϕ from spatially varying orientation

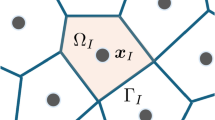

In this section we summarize the methodology presented in Groen et al. (2020) to obtain smooth and continuous mapping functions \(\boldsymbol {\phi } = \left \{\phi _{1}, \phi _{2}, \phi _{3}\right \}\) from 3 smooth and continuous orthogonal vector fields \(\left \{\boldsymbol {n}^{1},\boldsymbol {n}^{2},\boldsymbol {n}^{3}\right \}\). The theory to extract these smooth and continuous vector fields from the optimized microstructure orientation is discussed in more detail in Groen et al. (2020).

From (8) and (9) it follows that if a lamination direction has no width, i.e., wi = 0, it is not important how the corresponding mapping function ϕi looks. Furthermore, if a microstructure is solid, i.e., ρ = 1, then all mapping functions at that point can be relaxed. Hence, we require only an accurate description of ϕi in Ωi,

To solve for ϕi we solve the following least-squares problem,

Here ti,1 and ti,2 span a plane tangent to ni, i.e., for n1 we have t1,1 = n2 and t1,2 = n3. The domain is split into three parts, which dictate the weights on the objective \({\alpha ^{i}_{1}}\) and the weights on the constraints \({\alpha ^{i}_{2}}\) that allow us to relax ϕi outside Ωi,

Numerically, the above-mentioned problem can be solved using a finite element approach on a regular grid. Where the grid can be of similar resolution as \(\mathcal {T}^{c}\). Furthermore, the constraints are enforced in an augmented setting using a penalty parameter γϕ = 1000. We can impose an average unit-cell spacing ε. To do so, we define the periodicity scaling parameter Pi based on the average lattice spacing in the domain of interest \(\tilde {\varOmega }_{i}\),

From the mapping function ϕi we can identify the local distance between each plate λi using,

This local spacing can be used to get a description of the actual feature size of the geometry fi for each lamination direction i.

This description can then be used to modify the width wi to add a minimum feature size fmin to avoid very thin plates. Another option can be to impose a uniform feature size fi in the entire domain, as can be seen in Fig. 7c.

Rights and permissions

About this article

Cite this article

Groen, J.P., Thomsen, C.R. & Sigmund, O. Multi-scale topology optimization for stiffness and de-homogenization using implicit geometry modeling. Struct Multidisc Optim 63, 2919–2934 (2021). https://doi.org/10.1007/s00158-021-02874-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-021-02874-7