Abstract

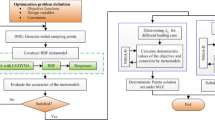

Tailor rolled blank (TRB) is an emerging steel rolling process to produce lightweight vehicle components. It allows continuous metal thickness changes, and as a result, it offers opportunities for automotive design in weight reduction, part complexity reduction, reduced capital investment, yet, maintains equal to or better strength characteristics. The objective of this research is to take advantages of the TRB manufacturing technology and combine with the advanced multidisciplinary design optimization (MDO) methodology to optimize vehicle structure. The process begins with noise vibration and harshness (NVH) optimization. The outputs of the optimal NVH response sensitivities are employed to build the first order response surface models. Uniform Latin Hypercube sampling and subset selection regression methods are used to construct the response surface models for the highly nonlinear impact and seatbelt pull responses. The optimal NVH design is then used as the starting point for MDO to obtain the optimal thickness profiles for the TRB parts. A vehicle application considering multiple impact modes, seatbelt pulls, and NVH, is used to demonstrate the proposed process for vehicle underbody TRB design. Results of this MDO TRB study is presented and discussed.

Similar content being viewed by others

References

Chatti S, Heller B, Kleiner M, Ridane N (2002) Forming and further processing of tailor rolled blanks for lightweight structures. Adv Technol Plasticity 2:1387–1392

Fang K, Lin D, Winker P, Zohang Y (2000) Uniform design: theory and application. Technometrics 42:237–248

Glad M, Muller-Bechtel M (2005) Thickness optimization as a tool for evaluation of structures. NAFEMS Seminar: optimization in structural mechanics, Wiesbaden, Germany

Gu L, Yang RJ (2006) On reliability-based optimization methods for automotive structures. Int J Mater Prod Technol 25, Nos. 1/2/3

Gu L, Yang RJ, Tho C, Makowski M, Faruque O, Li Y (2001) Optimization and robustness for crashworthiness of side impact. Int J Veh Des 26:348–360

Hoope A, Kaufmann M, Lauber B (2005) Multidisciplinary optimization considering crash and NVH loadcases. ATZ/MTZ Virtual Product Creation

Kleiner M, Geiger M, Klaus A (2003) Manufacturing of lightweight components by metal forming. ANNALS-CIRP 52:521–542

Kodiyalam S, Yang RJ, Gu L, Tho C (2002) Large scale multidisciplinary optimization of a vehicle system in a scalable, high performance computing environment. DETC/DAC-21082, Pittsburg

McKay MD, Bechman RJ, Conover WJ (1979) A comparison of three methods for selecting values of input variable in the analysis of output from a computer code. Technometrics 21:239–245

Miller AJ (1990) Subset selection in regression. Chapman & Hall, London

Mullerschon H, van den Hove M, Mlekiusch B (2006) Optimization strategies for highly non-linear FE-applications as crashworthiness. European conference on computational mechanics solids, structures and coupled problems in engineering, Lisbon, Portugal

National Highway Traffic Safety Administration Federal Motor Vehicle Safety Standards (1999) Standard No. 207-seating systems and standard No. 201-seat belt assembly anchorages. Washington, DC

Redhe M, Nilsson L (2004) Optimization of the new Saab 9-3 exposed to impact load using a space mapping technique. Struct Multidiscipl Optim 27:411–420

Rehse M (2006) Flexible rolling technologies (Tailor Rolled Blanks). Great designs in steel

Sener JY, De Medeiros C, Lescart JC, Marron G, Antoine P, Delfanne S (2002) Increasing performances by using multi-thicknesses blanks. SAE2002-01-2087

Sobieski JS, Kodiyalam S, Yang RJ (2001) Optimization of car body under constraints of noise, vibration, and harshness (NVH), and crash. Struct Multidiscipl Optim 22:295–305

Yang RJ, Gu L (2003) Experience with approximate reliability-based optimization methods. Struct Multidiscipl Optim 25:1–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chuang, C.H., Yang, R.J., Li, G. et al. Multidisciplinary design optimization on vehicle tailor rolled blank design. Struct Multidisc Optim 35, 551–560 (2008). https://doi.org/10.1007/s00158-007-0152-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-007-0152-0