Abstract

Heating green-wood prior to peeling is necessary to improve both peeling process and quality of veneer. This study investigates optimum heating temperatures by soaking of beech, birch and spruce. Experiments have studied the influence of heating temperatures from 20 to 80 °C on thickness deviations and veneer lathe checking using a pneumatic rugosimeter and image analysis of opening checks with the SMOF device (Système de Mesure de l’Ouverture des Fissures). Conclusions account for reduced heating temperatures compared to the temperatures currently in-use in the industry. Already at 50 °C, positive effects of heating ensure efficient peeling process. Low temperatures produce veneers with deeper and more spaced checks than high temperatures when checks are closer and less deep, becoming even unpredictable especially in case of spruce. These results establish the SMOF as an essential non-destructive control device to control the quality of the veneer produced at research level.

Zusammenfassung

Um den Schälprozess und die Qualität von Furnier zu verbessern, muss das Rundholz vor dem Schälen aufgeheizt werden. Dieser Artikel beschäftigt sich mit der Untersuchung der optimalen Aufheiztemperatur bei der Wässerung von Buche, Birke und Fichte. Unter Verwendung eines druckluftbetätigten Rugosimeters und digitaler Bildanalyse mittels SMOF-Apparat wurde der Einfluss einer Temperatur zwischen 20 und 80 °C auf die Dickenschwankungen und Risse der Furniere untersucht. Die Ergebnisse zeigen, dass die aktuell in der Industrie verwendeten Temperaturen reduziert werden könnten. Schon bei 50 °C kann ein effizienter Schälprozess erreicht werden. Bei niedrigeren Temperaturen treten tiefere Risse in größerem Abstand auf. Im Vergleich dazu sind bei höheren Temperaturen der Abstand und die Tiefe der Risse geringer, beim Schälen von Fichte sogar kaum meßbar. Die Ergebnisse zeigen, dass der SMOF-Apparat zur zerstörungsfreien Qualitätsprüfung von Furnieren im Rahmen von Forschungsarbeiten geeignet ist.

Similar content being viewed by others

References

Bédard N, Poulain A (2000) Application de l’infrarouge au réchauffage de billes pour produits forestiers Donohue—essais de laboratoires (Application of infrared heating to bolts for forest products Donohue—experimental tests). Technical report, Hydro Québec

Coelho CMP (2005) Influence de l’usinage du bois sur les caractéristiques objectives et sur la perception subjective de l’aspect d’une finition (Influence of wood machining on objective characteristics and subjective perception of the aspect of finishing). PhD thesis, Faculdade de Engenharia da Universidade do Porto

Dai C, Troughton GE (2011) Effect of log conditioning temperature on veneer quality. Technical report, FP Innovations

Daoui A, Douzet J, Marchal R, Zerizer A et al (2007) Valorisation du bois de pin d’alep par déroulage: optimisation de l’étuvage (Valorisation of Aleppo pine for peeling: optimisation of soaking). Bois et Forêts des Tropiques 294(4):51–64

Denaud LE, Bleron L, Eyma F, Marchal R (2012) Wood peeling process monitoring: a comparison of signal processing methods to estimate veneer average lathe check frequency. Eur J Wood Prod 70:253–261

Dupleix A, Ould Ahmedou SA, Bleron L, Rossi F, Hughes M (2012) Rational production of veneer by IR-heating of green wood during peeling: modeling experiments. Holzforschung (accepted)

El Haouzali H (2009) Déroulage du peuplier: effets cultivars et stations sur la qualité des produits dérivés (Peeling of poplar: effects of cultivars and stations on the quality of derived products) PhD thesis, Arts et Métiers ParisTech

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, reactions. Walter de Gruyter

Marchal R, Gaudilliere C, Collet R (2004) Technical feasibility of an embedded wood heating device on the slicer or the peeling lathe. 1st International Symposium Veneer Processing and Products Proceedings, pp 29–44

Meola C, Carlomagno GM, Giorlea L (2004) The use of infrared thermography for materials characterization. J Mater Process Technol 155:1132–1137

Mothe F (1985) Essai et comparaison de trois méthodes de classement de surface de bois massif pour leur rugosité: méthodes pneumatique et sensorielles (Test and comparison of three methods for grading the surface of solid wood for roughness: pneumatic and sensorial methods). Annales des Sciences Forestières 42(4):435–452

Mothe F (1988) Aptitude au déroulage du bois de Douglas. Conséquences de l’hétérogénéité du bois sur la qualité des placages. PhD thesis, Institut Polytechnique de Lorraine

Navi P, Heger F (2005) Comportement thermo-hydromécanique du bois: applications technologiques et dans les structures (Thermo-hydro-mechanical behaviour of wood: technological and structural applications). PPUR Presses Polytechniques

Olsson AM, Salmen L (1997) The effect of lignin composition on the viscoelastic properties of wood. Nord Pulp Pap Res 12(31):140–144

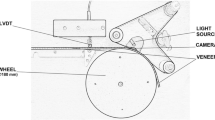

Palubicki B, Marchal R, Butaud JC, Denaud LE, Bleron L, Collet R, Kowaluk G (2010) A method of lathe checks measurement: SMOF device and its software. Eur J Wood Prod 68(2):151–159

Perre P (2007) Fundamentals of wood drying. A.R.BO.LOR

Pouzeau P, Pradal H (1957) Aspects nouveaux dans la technique de déroulage de l’Okoumé (New look in Okoumé peeling method). Bois et Forêts des Tropiques 54:41–50

Raiskila S, Saranpaa P, Fagerstedt K, Laakso T, Loija M, Mahlberg R, Paajanen L, Ritschkoff A (2006) Growth rate and wood properties of Norway spruce cutting clones on different sites. Silva Fenn 40(2):247–256

Tanritanir E, Hiziroglu S, As N (2006) Effect of steaming time on surface roughness of beech veneer. Build Environ 41(11):1494–1497

Thibaut B (1988) Le processus de coupe du bois par déroulage, PhD thesis, Institut Polytechnique de Lorraine

Thibaut B, Beauchene J (2004) Links between wood machining phenomena and wood mechanical properties: the case of 0°/90° orthogonal cutting of green wood, 2nd International Symposium on Wood Machining, pp 149–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dupleix, A., Denaud, LE., Bleron, L. et al. The effect of log heating temperature on the peeling process and veneer quality: beech, birch, and spruce case studies. Eur. J. Wood Prod. 71, 163–171 (2013). https://doi.org/10.1007/s00107-012-0656-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-012-0656-1