Abstract

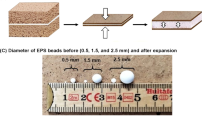

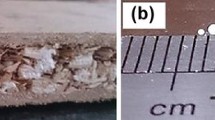

In the present paper, lightweight wood-based foam core panels were produced in a novel continuous process. Expandable microspheres (MS) and expandable polystyrene (EPS) were used as core materials. The influence of surface thickness and core materials on bending strength, internal bond and specific strength of the produced panel were investigated.

With increasing the surface thickness, bending strength was increased in both core types of panels. The internal bond value of the panels with expandable microspheres was steadily raised while the surface thickness was increased. The internal bond for the expandable polystyrene with increasing face thickness was reduced. In comparison with conventional particleboards, the specific bending strength and internal bond were increased. In addition, FE-SEM-microscopy and gamma-ray densitometry were used to characterize the panels.

Zusammenfassung

Leichte Schaumkernplatten wurden in einem neuartigen einstufigen Verfahren hergestellt. In zwei Plattenvarianten wurden als Mittellagenmaterialien expandierbare Mikrosphären (MS) und expandierbares Polystyrol (EPS) eingesetzt. Der Einfluss der Decklagendicke und des Kernmaterials auf Biegefestigkeit, Querzugfestigkeit und die korrespondierenden spezifischen Festigkeiten wurde untersucht.

Es konnte ein deutlicher Einfluss der Decklagendicke auf die Biegefestigkeiten beider Plattenvarianten und eine steigende Querzugfestigkeit der Platten mit MS-Mittellagen nachgewiesen werden. Die Querzugeigenschaften der Platten mit MS-Mittellagen reduzierten sich mit steigender Decklagendicke. Im Vergleich zu konventionellen Spanplatten konnte eine Erhöhung der spezifischen Biege- und Querzugfestigkeiten festgestellt werden. Die Analyse der Ergebnisse erfolgte mit Hilfe von FE-SEM-Mikroskopie und Gammastrahlen-Densitometrie.

Similar content being viewed by others

References

Allen HG (1969) Analysis and design of structural sandwich panels. Pergamon, Oxford

Karlsson K, Aström T (1997) Manufacturing and applications of structural sandwich components. Sci Ltd Part A (28A):97–111

Doroudiani S, Kortschot M (2004) Expanded wood fiber polystyrene composites: processing-structure-mechanical properties relationships. Thermoplast Compos Mater 17(1):13–30

Gibson LJ, Ashby MF (1982) The mechanics of three-dimensional cellular materials. Proc R Lond A 382:43–59

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Luedtke J, Welling J, Thoemen H, Barbu MC (2008a) Development of a continuous process for the production of lightweight panel boards. In: Ferreira AJM (ed) 8th international conference on sandwich structure ICSS8, Porto, Portugal

Luedtke J, Lohmann M, Thoemen H, Welling J (2008b) Foam core panels produced in a one-stage process: composition and specific properties. In: Hague J (ed) 9th Pacific Rim bio-based composites symposium, Rotorua, 6–8 November 2009

May-Pat A, Aviles F, Aguilar JO (2010) Mechanical properties of sandwich panels with perforated foam cores. J Sandw Struct Mater, 1–18

Michanickl A (2006) Development of a new light wood-based panel. In: 5th European wood-based panel symposium, Hannover, Germany

Vinson J (1999) The behavior of sandwich structures of isotropic and composite materials. Taylor and Francis Routledge, Pennsylvania

Wang Z, Gao L, Zhang G, Chang L (2008) Microscopic structure and properties of wood-based foaming composites. Eur J Wood Prod 3(3):357–379

Zenkert D (1997) The handbook of sandwich construction. Cradley Heath, Engineering Materials Advisory, UK

Acknowledgements

Sincere thanks are expressed to the “Ministry of Science, Research and Technology of Iran” for granting Ali Shalbafan a doctoral scholarship. The authors would also like to thank the companies Sunpor, AkzoNobel and BASF for providing materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shalbafan, A., Luedtke, J., Welling, J. et al. Comparison of foam core materials in innovative lightweight wood-based panels. Eur. J. Wood Prod. 70, 287–292 (2012). https://doi.org/10.1007/s00107-011-0552-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-011-0552-0