Abstract

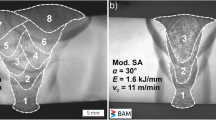

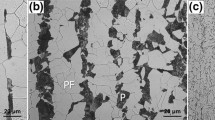

Modified 9Cr-1 Mo steel, being air hardenable is highly susceptible to hydrogen-assisted cracking (HAC). As welding is carried out using matching consumables, the weld metal is also equally susceptible to HAC. Preheating and post heating are generally employed to avoid HAC during fabrication. Susceptibility of indigenously developed modified 9Cr-1 Mo steel plate and shielded metal arc welding (SMAW) electrode has been evaluated using the implant test and the Gap — Bead on Plate (G-BOP) test. For both these tests the same base metal plate and consumable were employed. The variation of Lower Critical Stress (stress below which no cracking takes place, LCS) as a function of preheat temperature was studied using the implant test. Preheat temperature that would prevent cracking in the weld metal was determined from the G-BOP test. Results of the implant test showed that LCS without any preheat was only 185 MPa, considerably lower than the YS of fully hardened steel of ∼ 1 000 MPa. With increase in preheat temperature, LCS increased to up to 267 MPa for a preheat of 250 °C. The microstructural examination of the tested implant specimens revealed that though cracks initiated at the helical notch in the specimen, at high stress levels they propagated predominantly through the weld metal, and at low stress levels through the HAZ. Results of the G-BOP test, designed specifically to evaluate the weld metal susceptibility to HAC showed that the weld metal cracked soon after welding, when prepared without any preheating of the base plate. The weld metal did not crack for a preheat of 200 °C. Being a self-restraint test, in the tests conducted at a preheat of 150 °C, crack stopped in the midway of the weld metal with the release of stresses caused by cracking. Based on results obtained from both these tests, this paper discusses the HAC cracking in both the weld metal and the HAZ of modified 9Cr-1 Mo steel.

Similar content being viewed by others

References

Cold cracking test methods using implants, Doc. IIW-802, Welding in the World, 1985, vol. 23, no. 1/2, pp. 12-20.

Graville B.A. and McParlan M.: Weld metal cold cracking, Metal Construction and British Welding Journal, 1974, vol. 6, no. 2, pp. 62–63.

Chakravarti A.P. and Bala S.R.: Evaluation of weld metal cold cracking using G-BOP test, Welding Journal, 1989, vol. 68, no. 1, pp. 1s–8s.

Messler Jr R.: Principles of Welding, Process, Physics, Chemistry & Metallurgy, Chapter 17, Wiley Interscience, 1999, pp. 598-600.

Hart P.H.M.: Resistance to hydrogen cracking in steel weld metals, Welding Journal, 1986, vol. 65, no. 1, pp. 14s–17s.

Colombe G., Dibiez S., Donati J.R., Petreguin P. and Zacharie G.: Metallurgical aspects of weldability of Cr-Mo stabilized ferritic steels, Ferritic Steels for Fast Breeder Reactor Steam Generators, Ed. S.A. Pugh and E.A. Little, BNES London, 1978, pp. 447-458.

Hart P.H.M. and Watkinson E.: Weld metal implant test ranks Cr-Mo steels hydrogen cracking resistance, Welding Journal, 1975, vol. 54, no. 9, pp. 288s–295s.

Terai K., Shimazu S., Nakai Y., Murakami T., Ota S. and Fujiwara M.: Weldability and joint properties of advanced carbon stabilized 2.25Cr-1Mo Steels for LMFBR, Ferritic Steels for Fast Breeder Reactor Steam Generators, Ed. S.A. Pugh and E.A. Little, BNES London, 1978, pp. 442-446.

Lundin C.D., Henning J.A., Menon R. and Khan K.K.: Transformation, metallurgical response and behaviour of the weld fusion zone and HAZ in Cr-Mo steels for fossil energy applications, Report ORNL/Sub-81-07685/02-77, September 1987.

Lundin C.D., Milton R, Henning T.A., Richey M.W: Hydrogen assisted cracking sensitivity of Cr-Mo Steels during welding, Advances in Welding Science and Technology, Ed. by S.A. David, ASM International, Ohio, 1986, pp. 585–596.

Albert S.K., Ramasubbu V., Parvathavarthini N. and Gill T.P.S.: Influence of alloying on behaviour of diffusible hydrogen in Cr-Mo steels, Proceedings of the International Conference on the Joining of Materials, Helsingor, Denmark, May 16–19 1999, pp. 191-196.

Albert S.K., Ramasubbu V. and Gill T.P.S.: Hydrogen assisted cracking susceptibility of modified 9Cr-1 Mo steel, Proceedings of the International Conference on Welding, The Indian Institute of Welding, New Delhi, 2001.

Hirth J.P.: Theories of hydrogen induced cracking of steels, Hydrogen Embrittlement and Stress Corrosion Cracking, Cleveland,Ohio, 1984, pp. 29-41.

Wongpanya P., Boellinghaus Th. and Lothongkum G.: Numerical simulation of hydrogen removal heat treatment procedure in high strength steel welds, Mathematical modeling of weld phenomena, Ed. H. Cerjak, H.K. D.H. Bhadeshia and E. Kozeschnik, Graz University of Technology, 2007, pp.743-765.

Clerge M. and Boucher C.: Numerical simulation of intermediate heat treatment (DHT and ISR) of CrMo Steel Welds, Mathematical modeling of weld phenomena, Ed. H. Cerjak, H.K. D.H. Bhadeshia and E. Kozeschnik, Graz University of Technology, 2007, pp. 341-356.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Albert, S.K., Ramasubbu, V., Sundar Raj, S.I. et al. Hydrogen-Assisted Cracking Susceptibility of modified 9Cr-1 Mo steel and its weld metal. Weld World 55, 66–74 (2011). https://doi.org/10.1007/BF03321309

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321309