Abstract

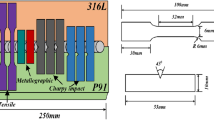

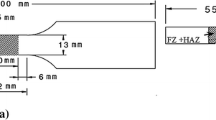

Dissimilar autogenous welding of ferritic/martensitic P92 steel and Inconel 617 alloy was conducted using the laser beam-welding process. The microstructure evolution such as element segregation, grain size, and precipitate morphology was investigated in different areas of the welded joint for as-welded (AW) and post-weld heat treatment (PWHT) condition by using optical microscopy (OM) and Field Emission Scanning Electron Microscopy (FE-SEM). The tensile strength at room temperature, microhardness variation, and Charpy V impact toughness was evaluated for the welded joint to study the effect of laser beam welding on mechanical properties. Finally, the fractured impact-tested specimen was characterized by FE-SEM. Microstructure observation showed the microstructure heterogeneity across the welded joint. A typical martensitic lath structure devoid of carbide precipitates was observed in P92 HAZ, while Inconel 617 HAZ exhibited the fine-equiaxed austenite grains of average size 24 ± 7 µm with Ti-enriched Ti(C, N) and Mo-enriched carbide precipitates. A columnar and cellular structure consisting of the alloying element segregation in the inter-dendritic areas was observed for the weld metal (WM) near the interface, while the interior WM showed the cellular and equiaxed dendrites along with particles of type NBC, TiC, and M23C6. Fairly good strength and ductility were obtained for the welded joint, and it qualified the ultra-supercritical (USC) boiler requirement. The WM was witnessed as the weakest part of the welded joint for impact strength. However, the impact strength of the WM (61 ± 2 J) was measured higher than the ASME standard value (> 41 J) and EN ISO 3580:2017 standard value (> 47 J) in the AW joint. After the PWHT, a drastic reduction in impact strength of WM (48 ± 3 J) was measured, and it was very close to EN ISO 3580:2017 recommended value of 47 J. The HAZ of P92 and Inconel 617 showed good impact strength for both AW and PWHT joints. The austenitic microstructure in WM exhibited the hardness of 150 ± 8 HV0.5, which was lower than the hardness of P92 and Inconel 617 base metal. The hardness in P92 HAZ was estimated higher than other regions of the weldments (WM and Inconel 617 HAZ). PWHT resulted in a drastic reduction in hardness of P92 HAZ, while WM (154 ± 7 HV0.5) and Inconel 617 HAZ showed a minute change in hardness value. The tensile strength of welded joints for the transverse tensile-tested specimen was also measured higher than the base metal, and fracture was observed in weaker parent metal, i.e., P92 steel for both AW and PWHT joint.

Similar content being viewed by others

References:

Di Gianfrancesco A, Blum R. 24—A-USC programs in the European union. Elsevier. 2017. https://doi.org/10.1016/B978-0-08-100552-1.00024-5.

Viswanathan R, Bakker W. Materials for ultrasupercritical coal power plants—boiler materials: part 1. J Mater Eng Perform. 2001;10:81–95.

Viswanathan R, Sarver J, Tanzosh JM. Boiler materials for ultra-supercritical coal power plants steamside oxidation. J Mater Eng Perform. 2006;15:255–74. https://doi.org/10.1361/105994906X108756.

Armaki HG, Chen R, Maruyama K, Lgarashi M. Creep behavior and degradation of subgrain structures pinned by nanoscale precipitates in strength-enhanced 5–12 % Cr ferritic steels. Metall Mater Trans A Phys Metall Mater Sci. 2011;42:3084–94. https://doi.org/10.1007/s11661-011-0726-8.

Yan W, Wang W, Shan YY, Yang K. Microstructural stability of 9–12%Cr ferrite/martensite heat-resistant steels. Front Mater Sci. 2013;7:1–27. https://doi.org/10.1007/s11706-013-0189-5.

Fetni S, Jhinaoui W, Boubahri C, Montero D, Briki J. Analysis of changes in lattice parameter of a grade 91 steel during thermal ageing at 550 °C. Eng Fail Anal. 2019;97:43–52. https://doi.org/10.1016/j.engfailanal.2018.12.006.

Sirohi S, Kumar P, Gupta A, Kumar S, Pandey C. Role of Ni-based filler on charpy impact toughness of the P91 welds joint. Mater Today Proc. 2021;44:1043–9. https://doi.org/10.1016/j.matpr.2020.11.177.

Yin H, Gao Y, Gu Y. Evolution of the microstructure and microhardness of the welding joint of IN 740H alloy with IN 617 as filler metal. Mater Charact. 2017;127:288–95. https://doi.org/10.1016/j.matchar.2017.01.011.

Zhang Y, Jing H, Xu L, Han Y, Zhao L, Xiao B. Microstructure and mechanical performance of welded joint between a novel heat-resistant steel and Inconel 617 weld metal. Mater Charact. 2018;139:279–92. https://doi.org/10.1016/j.matchar.2018.03.012.

Wang Y, Cui H, Fan M, Chen Y, Lu F. Characterization on the gradient microstructure near the fusion interface of dissimilar metal between high Cr heat-resistant steel and Ni-based Alloy 617. Mater Charact. 2019;151:227–36. https://doi.org/10.1016/j.matchar.2019.03.001.

Kumar S, Pandey C, Goyal A. Role of dissimilar IN617 nickel alloy consumable on microstructural and mechanical behavior of P91 welds joint. Arch Civ Mech Eng. 2020;20:99. https://doi.org/10.1007/s43452-020-00104-3.

Pandey C, Mahapatra MM, Kumar P, Saini N. Some studies on P91 steel and their weldments. J Alloys Compd. 2018;743:332–64. https://doi.org/10.1016/j.jallcom.2018.01.120.

Shamanian M, Kangazian J, Derakhshi MA, Szpunar JA. Microstructure and Mechanical Properties of Inconel 617/AISI 310 Electron Beam Welds. Metall Mater Trans A Phys Metall Mater Sci. 2019;50:3164–73.

Pavan AHV, Vikrant KSN, Ravibharath R, Singh K. Development and evaluation of SUS 304H–IN 617 welds for advanced ultra supercritical boiler applications. Mater Sci Eng A. 2015;642:32–41. https://doi.org/10.1016/j.msea.2015.06.065.

Zhang Y, Li K, Cai Z, Pan J. Creep rupture properties of dissimilar metal weld between Inconel 617B and modified 9%Cr martensitic steel. Mater Sci Eng A. 2019;764: 138185. https://doi.org/10.1016/j.msea.2019.138185.

Naffakh H, Shamanian M, Ashrafizadeh F. Microstructural evolutions in dissimilar welds between AISI 310 austenitic stainless steel and Inconel 657. J Mater Sci. 2010;45:2564–73. https://doi.org/10.1007/s10853-010-4227-8.

Sudha C, Paul VT, Terrance ALE, Saroja S, Vijayalakshmi M. Microstructure and microchemistry of hard zone in dissimilar weldments of Cr-Mo steels. Weld J (Miami, Fla). 85 (2006).

Dak G, Pandey C. Experimental investigation on microstructure, mechanical properties, and residual stresses of dissimilar welded joint of martensitic P92 and AISI 304L austenitic stainless steel. Int J Press Vessel Pip. 2021;194: 104536. https://doi.org/10.1016/j.ijpvp.2021.104536.

Sridhar R, DevendranathRamkumar K, Arivazhagan N. Characterization of microstructure, strength, and toughness of dissimilar weldments of inconel 625 and duplex stainless steel SAF 2205. Acta Metall Sin Engl Lett. 2014;27:1018–30. https://doi.org/10.1007/s40195-014-0116-5.

Sauraw A, Sharma AK, Fydrych D, Sirohi S, Gupta A, Świerczyńska A, Pandey C, Rogalski G. Study on microstructural characterization, mechanical properties and residual stress of GTAW dissimilar joints of P91 and P22 steels. Mater (Basel). 2021;14:6591. https://doi.org/10.3390/ma14216591.

Sirohi S, Pandey C, Goyal A. Role of heat-treatment and filler on structure-property relationship of dissimilar welded joint of P22 and F69 steel. Fusion Eng Des. 2020;159: 111935. https://doi.org/10.1016/j.fusengdes.2020.111935.

Kou S, Yang YK. Fusion-boundary macrosegregation in dissimilar-filler welds. Weld J (Miami Fla). 2007;86:303–12.

Jula M, Dehmolaei R, AlaviZaree SR. The comparative evaluation of AISI 316/A387-Gr.91 steels dissimilar weld metal produced by CCGTAW and PCGTAW processes. J Manuf Process. 2018;36:272–80. https://doi.org/10.1016/j.jmapro.2018.10.032.

Yang YK, Kou S. Evidence of macrosegregation near fusion boundary in welds made with dissimilar filler metals. In: Mater. Sci. Technol. Conf. Exhib. MS T’07 - "Exploring Struct. Process. Appl. Across Mult. Mater. Syst. 2007, 3220–3231.

Soysal T, Kou S, Tat D, Pasang T. Macrosegregation in dissimilar-metal fusion welding. Acta Mater. 2016;110:149–60. https://doi.org/10.1016/j.actamat.2016.03.004.

Shin KY, Lee JW, Han JM, Lee KW, Kong BO, Hong HU. Transition of creep damage region in dissimilar welds between Inconel 740H Ni-based superalloy and P92 ferritic/martensitic steel. Mater Charact. 2018;139:144–52. https://doi.org/10.1016/j.matchar.2018.02.039.

Seo WG, Suh JY, Shim JH, Lee H, Yoo K, Choi SH. Effect of post-weld heat treatment on the microstructure and hardness of P92 steel in IN740H/P92 dissimilar weld joints. Mater Charact. 2020;160: 110083. https://doi.org/10.1016/j.matchar.2019.110083.

Ahmad H, Hwang J, Lee J, Bae D. An assessment of the mechanical properties and microstructural analysis of dissimilar material welded joint between alloy 617 and 12Cr Steel. Metals (Basel). 2016;6:242. https://doi.org/10.3390/met6100242.

Ding K, Wang P, Liu X, Li X, Zhao B, Gao Y. Formation of lamellar carbides in Alloy 617-HAZ and their role in the impact toughness of alloy 617/9%Cr dissimilar welded joint. J Mater Eng Perform. 2018;27:6027–39. https://doi.org/10.1007/s11665-018-3668-0.

Ranjbar K, Dehmolaei R, Amra M, Keivanrad I. Microstructure and properties of a dissimilar weld between alloy 617 and A387 steel using different filler metals. Weld World. 2018;62:1121–36. https://doi.org/10.1007/s40194-018-0610-x.

Zhang Y, Fan M, Ding K, Zhao B, Zhang Y, He Y, Wang Y, Wu G, Wei T, Gao Y. Formation and control of the residual δ-ferrite in 9% Cr-HAZ of Alloy 617/9% Cr dissimilar welded joint. Sci Technol Weld Join. 2020. https://doi.org/10.1080/13621718.2020.1719622.

Shanmugarajan B, Sathiya P, Buvanashekaran G. Mechanical and metallurgical properties of autogenous laser welded P92 material. J Manuf Process. 2016;24:11–8. https://doi.org/10.1016/j.jmapro.2016.07.003.

Shanmugarajan B, Padmanabham G, Kumar H, Albert SK, Bhaduri AK. Autogenous laser welding investigations on modified 9Cr–1Mo (P91) steel. Sci Technol Weld Join. 2011;16:528–34. https://doi.org/10.1179/1362171811Y.0000000035.

Pandey C. Mechanical and metallurgical characterization of dissimilar P92/SS304 L welded joints under varying heat treatment regimes. Metall Mater Trans A. 2020;51:2126–42. https://doi.org/10.1007/s11661-020-05660-0.

Pandey C, Mahapatra MM. Effect of heat treatment on microstructure and hot Impact toughness of various zones of P91 welded pipes. J Mater Eng Perform. 2016;25:2195–210. https://doi.org/10.1007/s11665-016-2064-x.

Taheri N, Naffakh-Moosavy H, Ghaini FM. A new procedure for refurbishment of power plant Superalloy 617 by pulsed Nd:YAG laser process. Opt Laser Technol. 2017;91:71–9. https://doi.org/10.1016/j.optlastec.2016.12.013.

Ren W, Lu F, Yang R, Liu X, Li Z, Elmi Hosseini SR. A comparative study on fiber laser and CO2 laser welding of Inconel 617. Mater Des. 2015;76:207–14. https://doi.org/10.1016/j.matdes.2015.03.033.

Caiazzo F, Alfieri V, Cardaropoli F, Sergi V. Investigation on edge joints of Inconel 625 sheets processed with laser welding. Opt Laser Technol. 2017;93:180–6. https://doi.org/10.1016/j.optlastec.2017.03.011.

Bhanu V, Fydrych D, Gupta A, Pandey C. Study on microstructure and mechanical properties of laser welded dissimilar Joint of P91 steel and INCOLOY 800HT nickel alloy. Mater (Basel). 2021;14:5876.

Sirohi S, Gupta A, Pandey C, Vidyarthy RS, Guruloth K, Natu H. Investigation of the microstructure and mechanical properties of the laser welded joint. Opt Laser Technol. 2022;147: 107610. https://doi.org/10.1016/j.optlastec.2021.107610.

Vellaichamy L, Gerard PBT, Paulraj S. Mechanical and metallurgical characterization of laser welding on P91 ferritic steel and incoloy 800HT dissimilar joints. Mater Res. 2018. https://doi.org/10.1590/1980-5373-mr-2017-0911.

Sun Z. Feasibility of producing ferritic/austenitic dissimilar metal joints by high energy density laser beam process. Int J Press Vessel Pip. 1996;68:153–60. https://doi.org/10.1016/0308-0161(94)00048-4.

Ahmad GN, Raza MS, Singh NK, Kumar H. Experimental investigation on Ytterbium fiber laser butt welding of Inconel 625 and Duplex stainless steel 2205 thin sheets. Opt Laser Technol. 2020. https://doi.org/10.1016/j.optlastec.2020.106117.

Anawa EM, Olabi AG. Optimization of tensile strength of ferritic/austenitic laser-welded components. Opt Lasers Eng. 2008;46:571–7. https://doi.org/10.1016/j.optlaseng.2008.04.014.

Sun J, Ren W, Nie P, Huang J, Zhang K, Li Z. Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate using narrow gap laser welding method. Mater Des. 2019;175: 107823. https://doi.org/10.1016/j.matdes.2019.107823.

Sharma P, Dwivedi DK. A-TIG welding of dissimilar P92 steel and 304H austenitic stainless steel: mechanisms, microstructure and mechanical properties. J Manuf Process. 2019;44:166–78. https://doi.org/10.1016/j.jmapro.2019.06.003.

Shah Hosseini H, Shamanian M, Kermanpur A. Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds. Mater Charact. 2011;62:425–31. https://doi.org/10.1016/j.matchar.2011.02.003.

Lippold J, Kiser S, DuPont J. Welding metallurgy and weldability of nickel-base alloys. 2011.

Kuo TY, Lee HT. Effects of filler metal composition on joining properties of alloy 690 weldments. Mater Sci Eng A. 2002;338:202–12. https://doi.org/10.1016/S0921-5093(02)00063-1.

Pandey C, Mohan Mahapatra M, Kumar P, Thakre JG, Saini N. Role of evolving microstructure on the mechanical behaviour of P92 steel welded joint in as-welded and post weld heat treated state. J Mater Process Technol. 2018;263:241–55. https://doi.org/10.1016/j.jmatprotec.2018.08.032.

Standard S (2008) Welding consumables—covered electrodes for manual metal arc welding of creep- resisting steels—Classification (ISO 3580:2004). Com Eur Norm 1999.

DevendranathRamkumar K, Sridhar R, Periwal S, Oza S, Saxena V, Hidad P, Arivazhagan N. Investigations on the structure—property relationships of electron beam welded Inconel 625 and UNS 32205. Mater Des. 2015;68:158–66. https://doi.org/10.1016/j.matdes.2014.12.032.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest.

Research involving human participants and/or animals

This article does not contain any studies with animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Pandey, C. Autogenous laser-welded dissimilar joint of ferritic/martensitic P92 steel and Inconel 617 alloy: mechanism, microstructure, and mechanical properties. Archiv.Civ.Mech.Eng 22, 39 (2022). https://doi.org/10.1007/s43452-021-00365-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00365-6