Abstract

Ocean cobalt crust has attracted much attention due to the high economic potential of various metals. A large amount of industrial waste salt is usually filled or deposited without treatment, causing severe environmental pollution and waste of salt resources. In this work, to recover valuable metals (Cu, Co, Ni, and Mn) and NaCl from cobalt-rich crust and industrial waste salt and diminish energy consumption, a roasting coupling technology has been proposed and process and mechanism were investigated. In the reduction roasting process, the organic matter in industrial waste salt was continuously pyrolyzed, producing a large amount of reducing gases such as CO, CH4, and H2, which could react with the MnO2 and Fe2O3 in the cobalt-rich crust to destroy its original crystal structure. The results revealed that the reduction process of cobalt-rich crust was gradually completed from the surface layer of particles to the core. The NaCl and Cu, Co, Ni, and Mn in the roasting residues can be recovered by water leaching and acid leaching, respectively. Under the mass ratio of industrial waste salt to ocean cobalt-rich crust of 7:5, the roasting temperature of 973.15 K, and the roasting time of 25 min, the leaching efficiency of Cu, Co, Ni, and Mn reached 96.03%, 97.98%, 98.52%, and 99.74%, respectively, and the 98.49% recovery rate of NaCl could be achieved. The present process may simultaneously realize the extraction of metals from the cobalt-rich crust and the resource utilization of waste salt.

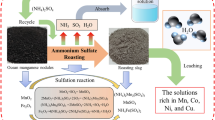

Graphical Abstract

Similar content being viewed by others

References

Martino S, Parson LM (2012) A comparison between manganese nodules and cobalt crust economics in a scenario of mutual exclusivity. Mar Policy 36(3):790–800

Du D, Wang C, Du X, Yan S, Ren X, Shi X, Hein JR (2017) Distance-gradient-based variogram and Kriging to evaluate cobalt-rich crust deposits on seamounts. Ore Geol Rev 84:218–227

Agterberg F (2009) Geochemical anomaly and mineral prospectivity mapping in GIS. Ore Geol Rev 35(3):455–456

Du D, Ren X, Yan S, Shi X, Liu Y, He G (2017) An integrated method for the quantitative evaluation of mineral resources of cobalt-rich crusts on seamounts. Ore Geol Rev 84:174–184

Yang Y, He G, Ma J, Yu Z, Yao H, Deng X, Liu F, Wei Z (2020) Acoustic quantitative analysis of ferromanganese nodules and cobalt-rich crusts distribution areas using EM122 multibeam backscatter data from deep-sea basin to seamount in Western Pacific Ocean, Deep Sea Research Part I: Oceanographic Research Papers 161:103281

Zhao B, Yang Y, Zhang X, He G, Lü W, Liu Y, Wei Z, Deng Y, Huang N (2020) Sedimentary characteristics based on sub-bottom profiling and the implications for mineralization of cobalt-rich ferromanganese crusts at Weijia Guyot, Western Pacific Ocean, Deep Sea Research Part I: Oceanographic Research Papers 158:103223

Maksimov SO, Safronov PP (2018) Geochemical features and genesis of continental cobalt-rich ferromanganese crusts. Russ Geol Geophys 59(7):745–762

Verlaan PA, Cronan DS, Morgan CL (2004) A comparative analysis of compositional variations in and between marine ferromanganese nodules and crusts in the South Pacific and their environmental controls. Prog Oceanogr 63(3):125–158

Koschinsky A, Halbach P (1995) Sequential leaching of marine ferromanganese precipitates: genetic implications. Geochim Cosmochim Acta 59(24):5113–5132

Zhao Q, Sun L, Wang G, Luo C, Shun Y, Yan K (2019) Novel reduction roasting and leaching method for manganese dioxide ore using FeP slag as the reductant. Hydrometallurgy 189:105113

Cheng Z, Zhu G, Zhao Y (2009) Study in reduction-roast leaching manganese from low-grade manganese dioxide ores using cornstalk as reductant. Hydrometallurgy 96(1):176–179

Zhang Y, You Z, Li G, Jiang T (2013) Manganese extraction by sulfur-based reduction roasting–acid leaching from low-grade manganese oxide ores. Hydrometallurgy 133:126–132

Xiong S, Li X, Liu P, Hao S, Hao F, Yin Z, Liu J (2018) Recovery of manganese from low-grade pyrolusite ore by reductively acid leaching process using lignin as a low cost reductant. Miner Eng 125:126–132

Kang JX, Feng YL, Li HR, Du ZW, Deng XY, Wang H (2019) Electrochemical behavior of ocean polymetallic nodules and low-grade nickel sulfide ore in acidithiobacillus ferrooxidans-coupled bio-leaching. Minerals 9(2):70

Ju J, Feng Y, Li H, Yu H, Wu H, Liu S (2021) The limiting effect of manganese phase of oceanic cobalt-rich crust reduction by sawdust in acid leaching. Sustain Chem Pharm 19:100346

Mishra D, Srivastava RR, Sahu KK, Singh TB, Jana RK (2011) Leaching of roast-reduced manganese nodules in NH3–(NH4)2CO3 medium. Hydrometallurgy 109(3):215–220

Singh V, Reddy KVK, Tripathy SK, Kumari P, Dubey AK, Mohanty R, Satpathy RR, Mukherjee S (2020) A sustainable reduction roasting technology to upgrade the ferruginous manganese ores. J Clean Prod 284:124784

Nagy G, Dobó Z (2020) Experimental investigation of fixed-bed pyrolysis and steam gasification of food waste blended with woody biomass. Biomass Bioenergy 139:105580

Santos J, Ouadi M, Jahangiri H, Hornung A (2020) Valorisation of lignocellulosic biomass investigating different pyrolysis temperatures. J Energy Inst 93(5):1960–1969

Kang HW, Lee KR, Choi J-H, Park H-S (2021) Aerosol processing of glass for radioactive salt waste immobilization. Ann Nucl Energy 151:107951

Zhao Y, Zhou Q, Hidetoshi K, Luo L (2021) Nitrogen flow characteristics of solid waste in China. Ecotoxicol Environ Saf 208:111596

Camacho JA, Ruíz-Peñalver SM, Rodríguez M (2020) Identification of leading hazardous waste generating industries with high improvement potential in Spain. Sci Total Environ 731:139207

Yuan HR, Wang YZ, Kobayashi N, Zhao DD, Xine SY (2015) Study of fuel properties of torrefied municipal solid waste. Energy Fuels 29(8):4976–4980

Liu S-J, Zheng M-X, Sun X-J, Xi B-D, He X-S, Xiao X (2020) Evolution properties and dechlorination capacities of particulate organic matter from a landfill. J Hazard Mater 400:123313

Jiang K, Cheng Z, Lou Z, Wang L, Lu H, Xu B, Jin N (2021) Chemical and olfactive impacts of organic matters on odor emission patterns from the simulated construction and demolition waste landfills. J Environ Sci 103:196–206

Randazzo A, Asensio-Ramos M, Melián GV, Venturi S, Padrón E, Hernández PA, Pérez NM, Tassi F (2020) Volatile organic compounds (VOCs) in solid waste landfill cover soil: chemical and isotopic composition vs. degradation processes. Sci Total Environ 726:138326

Han Y, Wang Y, Chai F, Ma J, Li L (2020) Biofilters for the co-treatment of volatile organic compounds and odors in a domestic waste landfill site. J Clean Prod 277:124012

Giro-Paloma J, Mañosa J, Maldonado-Alameda A, Quina MJ, Chimenos JM (2019) Rapid sintering of weathered municipal solid waste incinerator bottom ash and rice husk for lightweight aggregate manufacturing and product properties. J Clean Prod 232:713–721

Chen W, He C, Zhuo X, Wang F, Li Q (2020) Comprehensive evaluation of dissolved organic matter molecular transformation in municipal solid waste incineration leachate. Chem Eng J 400:126003

Asakura H, Endo K, Yamada M, Inoue Y, Ono Y, Ono Y (2010) Influence of oxygen flow rate on reaction rate of organic matter in leachate from aerated waste layer containing mainly incineration ash. Waste Manag 30(11):2185–2193

Zhang S, Herbell J-D, Gaye-Haake B (2004) Biodegradable organic matter in municipal solid waste incineration bottom ash. Waste Manag 24(7):673–679

Astrup T, Mosbæk H, Christensen TH (2006) Assessment of long-term leaching from waste incineration air-pollution-control residues. Waste Manag 26(8):803–814

AmuthaRani D, Boccaccini AR, Deegan D, Cheeseman CR (2008) Air pollution control residues from waste incineration: current UK situation and assessment of alternative technologies. Waste Manag 28(11):2279–2292

Alibardi L, Astrup TF, Asunis F, Clarke WP, De Gioannis G, Dessì P, Lens PNL, Lavagnolo MC, Lombardi L, Muntoni A, Pivato A, Polettini A, Pomi R, Rossi A, Spagni A, Spiga D (2020) Organic waste biorefineries: looking towards implementation. Waste Manag 114:274–286

Girotto F, Alibardi L, Cossu R (2015) Food waste generation and industrial uses: a review. Waste Manag 45:32–41

Ma H, Guo Y, Qin Y, Li Y-Y (2018) Nutrient recovery technologies integrated with energy recovery by waste biomass anaerobic digestion. Biores Technol 269:520–531

Moško J, Pohořelý M, Cajthaml T, Jeremiáš M, Robles-Aguilar AA, Skoblia S, Beňo Z, Innemanová P, Linhartová L, Michalíková K, Meers E (2021) Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere 265:129082

Luo J, Lin J, Ma R, Chen X, Sun S, Zhang P, Liu X (2020) Effect of different ash/organics and C/H/O ratios on characteristics and reaction mechanisms of sludge microwave pyrolysis to generate bio-fuels. Waste Manag 117:188–197

Gao R, Liu B, Zhan L, Guo J, Zhang J, Xu Z (2021) Catalytic effect and mechanism of coexisting copper on conversion of organics during pyrolysis of waste printed circuit boards. J Hazard Mater 403:123465

Nuagah MB, Boakye P, Oduro-Kwarteng S, Sokama-Neuyam YA (2020) Valorization of faecal and sewage sludge via pyrolysis for application as crop organic fertilizer. J Anal Appl Pyrolysis 151:104903

Vereshchagin OS, Perova EN, Brusnitsyn AI, Ershova VB, Khudoley AK, Shilovskikh VV, Molchanova EV (2019) Ferro-manganese nodules from the Kara Sea: mineralogy, geochemistry and genesis. Ore Geol Rev 106:192–204

Acknowledgements

We are deeply grateful to COMRA for providing samples of this study. We gratefully acknowledge the financial support from the long-term special project for National (Project No. JS-KTHT-2019-01) and the key Laboratory of Biochemical Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China. Help from the Analytical & Testing Center of University of Science and Technology Beijing is also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This article has not been published elsewhere in whole or in part. All authors have read and approved the content and agreed to submit for consideration for publication in the journal. There are no ethical/legal conflicts involved in the article. The article will not be published elsewhere in the same form, in any language, without the written authorization of the Publisher.

Additional information

The contributing editor for this article was Zhi Sun.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ju, J., Feng, Y., Li, H. et al. Recovery of Valuable Metals and NaCl from Cobalt-Rich Crust and Industrial Waste Salt via Roasting Coupling Technology. J. Sustain. Metall. 7, 1862–1875 (2021). https://doi.org/10.1007/s40831-021-00464-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00464-x