Abstract

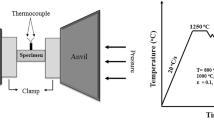

Damping properties of two austenitic stainless steel grades, EN 1.4318 and EN 1.4301, were investigated. The test materials were cold rolled to different reductions and damping capacity was measured as a function of temperature with an internal friction method. Microstructures of the test materials were studied by means of X-ray diffraction (XRD) and magnetic measurements. The results showed that damping capacity of the studied materials depended on the amounts of strain-induced ε- and α′-martensite phases. At temperatures around 0 °C, highest damping capacity was achieved with cold rolling reduction of 10 to 15 pct. This behavior is related to the existence of ε-martensite and stacking faults. Internal friction peak due to α′-martensite phase was present at the temperature of 130 °C. Strain aging heat treatment at 200 °C for 20 minutes decreased the damping capacity in the entire studied temperature range.

Similar content being viewed by others

References

M.W. Bowkett, S.R. Keown, and D.R. Harries: Met. Sci., 1982, vol. 16, pp. 499–517.

P.L. Mangonon and G. Thomas: Metall. Trans., 1970, vol. 1, pp. 1577–86.

P.L. Mangonon and G. Thomas: Metall. Trans., 1970, vol. 1, pp. 1587–94.

K. Nohara, Y. Ono, and N. Ohashi: J. Iron Steel Inst. Jpn., 1977, vol. 63, pp. 212–22.

R.E. Schramm and R.P. Reed: Metall. Trans., 1974, vol. 6, pp. 1345–51.

V.R. Baraz, S.V. Grachev, and L.D. Rolschikov: Steel USSR, 1972, vol. 2, pp. 670–72.

N. Igata, H.B. Chen, and K. Miyahara: Scripta Metall., 1982, vol. 16, pp. 169–72.

N. Igata, H.B. Chen, and K. Miyahara: Scripta Metall., 1982, vol. 16, pp. 1039–42.

S.S. Hecker, M.G. Stout, K.P. Staudhammer, and J.L. Smith: Metall. Trans. A, 1982, vol. 13A, pp. 619–26.

B.D. Cullity and S.R. Stock: Elements of X-Ray Diffraction, 3rd ed., Prentice-Hall Inc., Elmsford, NJ, 2001.

International Tables for X-Ray Crystallography, Volume III, Physical and Chemical Tables, C.H. MacGillavry and G.D. Rieck, eds., Reidel Publishing Company, Dordrecht, Netherlands, 1985.

M.S. Paterson: J. Appl. Phys., 1952, vol. 23, pp. 805–11.

B.E. Warren: X-Ray Diffraction, Dover Publications Inc., New York, NY, 1990.

H. Fujita and S. Ueda: Acta Metall., 1972, vol. 20, pp. 759–67.

Y.-K. Lee, J.-H. Jun, and C.-S. Choi: Scripta Mater., 1996, vol. 35, pp. 825–30.

V.G. Gavriljuk, P.G. Yakovenko, and K. Ullakko: Scripta Mater., 1998, vol. 38, pp. 931–35.

R.W. Rathbun, D.K. Matlock, and J.G. Speer: Scripta Mater., 2000, vol. 42, pp. 887–91.

J. Talonen, P. Nenonen, and H. Hänninen: Helsinki University of Technology, Helsinki, unpublished research, 2004.

K. Enami, S. Nenno, and Y. Minato: Trans. JIM, 1977, vol. 18, pp. 435–42.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Talonen, J., Hänninen, H. Damping properties of austenitic stainless steels containing strain-induced martensite. Metall Mater Trans A 35, 2401–2406 (2004). https://doi.org/10.1007/s11661-006-0220-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0220-x