Abstract

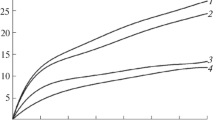

The structure and physicomechanical properties of composite materials based on boron nitride within which new phases (mullite and sialon) form during hot compaction are studied. It is established that the microstructure of composites is specified by their texture formation caused by the crystal morphology of boron nitride particles and it is almost independent of composite phase composition. It is shown that the main factor that affects strength is porosity. The dependence of strength on porosity is exponential in character. The strength of boron nitride-mullite and boron nitride-sialon composites is 110–140 MPa and at 20–1200°C it is almost unchanged.

Similar content being viewed by others

References

G. I. Savvakin, T. V. Dubovik, and G. S. Oleinik, “Structural study of ceramics based on graphite-like boron nitride subjected to detonation treatment,” Poroshk. Metall., Nos. 5–6, 75–80 (1995).

A. Lipp, K. A. Schwetz, and K. Hunold, “Hexagonal boron nitride: fabrication, properties and application,” J. Europ. Ceram. Soc., No. 5, 3–9 (1989).

T. Mah and K. S. Mazdiyashi, “Mechanical properties of mullite,” J. Amer. Ceram. Soc., No. 10, 699–703 (1983).

I. L. Boyarina, A. B. Puchkov, A. M. Gavrish, et al., “Sialon, a new refractory material,” Ogneupory, No. 12, 24–27 (1981).

Ya. L. Grushevskii, V. I. Frolov, I. L. Shabalin, and A. V. Cheboryukov, “Mechanical behavior of ceramics containing boron nitride,” Poroshk. Metall., No. 4, 89–92 (1991).

G. Philippe and D. B. Hoggard, Composite Material, Pat. 1002776 EP, Publ. May 24 (2000).

H. Zhao, W. Li, X. Zhong, and J. Wang, “Study of thermal shock resistance of zirconia-corundum-mulliteboron nitride system composites,” J. Chin. Ceram. Soc., 24, No. 3, 311–316 (1996).

Gr. W. Shaffer, et al., Method of Producing Mullite/Yttria Stabilized Zirconia/Boron Nitride Composites,” Pat. 5.134.098 US, Publ. June 28 (1992).

L. Sigl and H. Thaler, Verbundwerkstoffe und Formkorper Soviet Verfahren zu Ihrer Herstellung, Pat. 01519492 EP, Publ. June 19 (1992).

K. Kabushiki, M. Nakashima, S. Kurita, et al., Boron Nitride Ceramic Having Excellent Resistance Against Fusing Damage, Pat. 90.05122 WO, Publ. May 17 (1990).

P. Sindhauser, K. Hunold, and A. Lipp, Gesinterte Polycristalline Mischwerkstoffe auf Bornitridbasis, Pat. 3510111 DE, Publ., September 25 (1986).

L. N. Pereselentseva, A. K. Barshchevskaya, T. V. Tomila, and A. V. Maznaya, “Study of the structure-and phase-formation during preparation of composites in the system B-N-Al-Si-O,” Proc. Internat. Conf. “Newest Technology in Powder Metallurgy and Ceramics” (8–12 Sept. 2003, Kiev), Kiev (2003).

R. A. Andrievskij, Introduction in Powder Metallurgy, Ilim, Frunze (1988).

L. N. Rusanova, A. G. Romashin, G. I. Kulikova, and O. P. Golubeva, “Problems and prospects in developing ceramics of boron nitride,” Poroshk. Metall., No. 1, 23–30 (1988).

E. S. Lukin and N. A. Makarov, “Selection of additions in technology of corundum ceramics with lowered sintering temperature,” Ogneupory i Techn. Keramica, No. 9, 11–13 (1999).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 5–6(449), pp. 33–39, May–June, 2006.

Rights and permissions

About this article

Cite this article

Vishnyakov, L.R., Maznaya, A.V., Pereselentseva, L.N. et al. Structure and high-temperature strength of composite materials based on boron nitride. Powder Metall Met Ceram 45, 239–243 (2006). https://doi.org/10.1007/s11106-006-0070-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0070-5