Abstract

Objectives

To develop a recombinant human factor IX (rFIX) formulation equivalent to commercially available products in terms of cake appearance, residual moisture, proportion of soluble aggregates and activity maintenance for 3 months at 4–8 °C.

Results

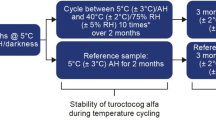

NaCl and low bulking agent/cryoprotectant mass ratio had a negative impact on cake quality upon lyophilisation for a wide range of formulations tested. Particular devised formulations maintained rFIX activity after lyophilization with a similar performance when compared with the rFIX formulated using the excipients reported for a commercially available FIX formulation (Benefix). rFIX remained active after 3 months when stored at 4 °C, though this was not the case with samples stored at 40 °C. Interestingly, particular formulations had an increase in residual moisture after 3 months storage, but not above a 3% threshold. All four formulations tested were equivalent to the Benefix formulation in terms of particle size distribution and cake appearance.

Conclusions

Three specific formulations, consisting of surfactant polysorbate-80, sucrose or trehalose as cryoprotectant, mannitol or glycine as bulking agent, l-histidine as buffering agent, and NaCl added in the reconstitution liquid at 0.234% (w/v) were suitable for use with a CHO cell-derived recombinant FIX.

Similar content being viewed by others

References

Amaral RL, Bomfim AS, Abreu-Neto MS, Picanço-Castro V, Russo EMS, Covas DT, Swiech K (2016) Approaches for recombinant human factor IX production in serum-free suspension cultures. Biotechnol Lett 38:385–394

Baxalta Canada Corporation (2015) Product Monograph Rixubis Recombinant Coagulation Factor IX (rFIX), Nonacog gamma. http://www.baxalta.ca/downloads/Product_Monographs/en/Rixubis.pdf. Accessed 4 November 2016

Bush L, Webb C, Bartlett L, Burnett B (1998) The formulation of recombinant factor IX: stability, robustness, and convenience. Semin Hematol 35:18–21

EMEA (2005) Scientific Discussion.http://www.ema.europa.eu/docs/en_GB/document_library/EPAR_-_Scientific_Discussion/human/000139/WC500020386.pdf. Accessed 12 March 2017

Gourbatsi E, Povey J, Uddin S, Smales CM (2016) Biotherapeutic protein formulation variables influence protein integrity and can promote post-translational modifications as shown using chicken egg white lysozyme as a model system. Biotechnol Lett 38:589–596

Jameel F, Pikal MJ (2010) Design of a formulation for freeze drying. In: Jameel F, Hershenson S (eds) Formulation and process development strategies for manufacturing biopharmaceuticals. Wiley, New Jersey, pp 459–492

Johnson RE, Kirchhoff CF, Gaud HT (2002) Mannitol-sucrose mixtures: versatile formulations for protein lyophilization. J Pharm Sci 91:914–922

Kasper JC (2011) The freezing step in lyophilization: physico-chemical fundamentals, freezing methods and consequences on process performance and quality attributes of biopharmaceuticals. Eur J Pharm Biopharm 78:248–263

Lambert T, Recht M, Valentino LA, Powell JS, Udata C, Sullivan ST, Roth DA (2007) Reformulated BENEFIX: efficacy and safety in previously treated patients with moderately severe to severe haemophilia B. Haemophilia 13:233–243

Liao X, Krishnamurthy R, Suryanarayanan R (2005) Influence of the active pharmaceutical ingredient concentration on the physical state of mannitol—implications in freeze-drying. Pharm Res 22:1978–1985

Lim I, Kim JS, Lee G, Choi M, Yoon Y (2010) The effects of medium supplement on high-level production of recombinant human factor IX in CHO cell. In: Noll T (ed) Cells and culture. Springer, Dordrecht, pp 613–618

Lim JY, Kim NA, Lim DG et al (2016) Process cycle development of freeze drying for therapeutic proteins with stability evaluation. J Pharm Invest 46:519–536

Pansare SK, Patel SM (2016) Practical considerations for determination of glass transition temperature of a maximally freeze concentrated solution. AAPS PharmSciTech 17:805–819

Passot S, Tréléa IC, Marin M, Fonseca F (2010) The relevance of thermal properties for improving formulation and cycle development: application to freeze-drying of proteins. In: Rey L, May JC (eds) Freeze drying/lyophilization of pharmaceutical and biological products, 3rd edn. Inf Healthc, New York, pp 136–166

Pfizer (2012) Product Monograph Benefix Coagulation Factor IX (recombinant). http://www.pfizer.ca/sites/g/files/g10017036/f/201410/BENEFIX_PM_E_153056_27Dec2012.pdf. Accessed 4 November 2016

Povey JP, Perez-Moral N, Noel TR, Parker R, Howard MJ, Smales CM (2009) Investigating variables and mechanisms that influence protein integrity in low water content amorphous carbohydrate matrices. Biotechnol Prog 25:1217–1227

Ribeiro DA (2013) Processo de purificação de fator IX recombinante produzido em células da linhagem CHO. Ph.D. thesis, Federal University of Rio de Janeiro (Brazil)

Ribeiro DA, Passos DP, Ferraz HC, Castilho LR (2013) Anion-exchange purification of recombinant factor IX from cell culture supernatant using different chromatography supports. J Chrom B 938:111–118

Ronzi E, Capolongo A, Rovero G, Bucci E, Mondini S, Falbo A (2003) Optimisation of a freeze-drying process of high purity factor VIII and factor IX concentrates. Chem Eng Proc 42:751–757

Smales CM, Pepper DS, James DC (2002) Protein modification during anti-viral heat-treatment bioprocessing of factor VIII concnetrates, factor IX concentrates, and model proteins in the presence of sucrose. Biotechnol Bioeng 77:37–48

Tang X, Pikal MJ (2004) Design of freeze-drying processes for pharmaceuticals: practical advice. Pharm Res 21:191–200

Vatandoost J, Bos MH (2016) Efficient expression of functional human coagulation factor IX in stably-transfected Drosophila melanogaster S2 cells; comparison with the mammalian CHO system. Biotechnol Lett 38:1691–1698

Wang W (2000) Lyophilization and development of solid protein pharmaceuticals. Int J Pharm 203:1–60

Webb C, Bush L, Schaub RG (1997) Highly concentrated, lyophilized, and liquid factor IX formulations. Patent WO 1997026909:A1

Acknowledgements

The authors would like to thank CNPq, Capes, FAPERJ, BNDES, and Hemobras for the financial support of this research project, and the University of Kent for their support and laboratory facilities to enable these experiments. CMS thanks the Royal Society for an Industrial Fellowship (IF130004).

Supporting information

Supplementary Table 1—Excipients and concentration ranges used in the Design of Experiments (DoE).

Supplementary Table 2—Two-level fractional factorial design of experiment (resolution IV) showing the 3 categorical factors and the 5 numeric factors (concentration ranges).

Supplementary Fig. 1—DSC thermal analysis of rFIX samples formulated with Benefix (A) and Rixubis (B) excipients.

Supplementary Fig. 2—Cake appearance after the lyophilisation of formulations A to D, rFIX formulated with Benefix excipients and the condition with no excipients (just rFIX).

Supplementary Fig. 3—Particle size profiles (by DLS) of formulations A to D, rFIX formulated with Benefix excipients and the condition with no excipients for all three time points analyzed.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Almeida, A.G., Pinto, R.C.V., Smales, C.M. et al. Investigations into, and development of, a lyophilized and formulated recombinant human factor IX produced from CHO cells. Biotechnol Lett 39, 1109–1120 (2017). https://doi.org/10.1007/s10529-017-2353-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-017-2353-y