Abstract

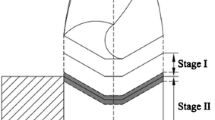

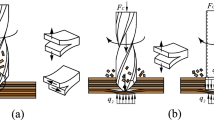

Delamination is one of the major damages associated with drilling carbon fiber-reinforced plastics (CFRP), Peel-up and Push-out are two recognizable delamination mechanisms, while drilling without using a back-up plate under the workpiece complicates the delamination mechanism even more. Minimizing delamination is dependent on many factors such as cutting parameters, geometry and type of drill bits used. The objective of this study is to present a new approach to measure the equivalent adjusted delamination factor (F e d a ) when drilling unidirectional CFRP laminates without using a back-up plate and comparing it experimentally and numerically with conventional delamination factor (F d ) and adjusted delamination factor (F d a ). A polycrystalline diamond (PCD) twist drill and a special diamond coated double point angle drill was used for drilling in this study. The 3D finite element model was developed in ANSYS-Explicit to simulate the drilling process using the ply-based modeling method instead of a conventional zone-based concept. Experimental drilling validation process was implemented by utilizing a CNC machining center. Results show that the F e d a obtained is suitable to estimate the drilling induced damages, damage analysis shows that good agreements were obtained from the experiments and finite element method (FEM) simulation, while the special diamond coated double point angle drill seemed to provide a better hole quality, and drilling induced damage is highly affected by feed rate which is considered one of the important parameter.

Similar content being viewed by others

References

Sanda A, Arriola I, Garcia Navas V, Bengoetxea I, Gonzalo O (2016) Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V. J Manuf Process 22:169–176. doi:10.1016/j.jmapro.2016.03.003

Isbilir O, Ghassemieh E (2013) Numerical investigation of the effects of drill geometry on drilling induced delamination of carbon fiber reinforced composites. Compos Struct 105:126–133. doi:10.1016/j.compstruct.2013.04.026

Wang X, Kwon PY, Sturtevant C, Kim D, Lantrip J (2013) Tool wear of coated drills in drilling CFRP. J Manuf Process 15(1):127–135. doi:10.1016/j.jmapro.2012.09.019

Madhavan V, Lipczynski G, Lane B, Whitenton E (2015) Fiber orientation angle effects in machining of unidirectional CFRP laminated composites. J Manuf Process 20, Part 2:431–442. doi:10.1016/j.jmapro.2014.06.001

Feito N, López-Puente J, Santiuste C, Miguélez MH (2014) Numerical prediction of delamination in CFRP drilling. Compos Struct 108:677–683. doi:10.1016/j.compstruct.2013.10.014

Gudimetla P, Kharidi A, Yarlagadda P (2009) Simulation of delaminations in composite laminates. In: Proceedings of the 6th international conference on precision, meso, micro and nano engineering

Durão LMP, Tavares JMRS, de Albuquerque VHC, Gonçalves DJS (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct 96:576–583. doi:10.1016/j.compstruct.2012.08.003

Grilo TJ, Paulo RMF, Silva CRM, Davim JP (2013) Experimental delamination analyses of CFRPs using different drill geometries. Compos Part B Eng 45(1):1344–1350. doi:10.1016/j.compositesb.2012.07.057

Tsao CC, Hocheng H, Chen YC (2012) Delamination reduction in drilling composite materials by active backup force. CIRP Ann Manuf Technol 61(1):91–94. doi:10.1016/j.cirp.2012.03.036

Shyha IS, Soo SL, Aspinwall DK, Bradley S, Perry R, Harden P, Dawson S (2011) Hole quality assessment following drilling of metallic-composite stacks. Int J Mach Tools Manuf 51(7–8):569–578. doi:10.1016/j.ijmachtools.2011.04.007

Gaitonde V, Karnik S, Rubio JC, Correia AE, Abrão A, Davim JP (2011) A study aimed at minimizing delamination during drilling of CFRP composites. J Compos Mater 45(22):2359–2368

Tsao CC (2008) Prediction of thrust force of step drill in drilling composite material by Taguchi method and radial basis function network. Int J Adv Manuf Technol 36(1-2):11–18. doi:10.1007/s00170-006-0808-8

Bednarcyk BA, Stier B, Simon J-W, Reese S, Pineda EJ (2015) Meso- and micro-scale modeling of damage in plain weave composites. Compos Struct 121:258–270. doi:10.1016/j.compstruct.2014.11.013

Phadnis VA, Makhdum F, Roy A, Silberschmidt VV (2013) Drilling in carbon/epoxy composites: experimental investigations and finite element implementation. Compos A: Appl Sci Manuf 47:41–51. doi:10.1016/j.compositesa.2012.11.020

Niezgoda T, Derewońko A (2009) Multiscale composite FEM modeling. Procedia Eng 1(1):209–212. doi:10.1016/j.proeng.2009.06.049

Cherniaev A, Telichev I (2015) Meso-scale modeling of hypervelocity impact damage in composite laminates. Compos Part B Eng 74:95–103. doi:10.1016/j.compositesb.2015.01.010

Stier B, Simon JW, Reese S (2015) Comparing experimental results to a numerical meso-scale approach for woven fiber reinforced plastics. Compos Struct 122:553–560. doi:10.1016/j.compstruct.2014.12.015

Han M-G, Chang S-H (2015) Failure analysis of a Type III hydrogen pressure vessel under impact loading induced by free fall. Compos Struct 127:288–297. doi:10.1016/j.compstruct.2015.03.027

Stelzmann IU, Hörmann IM (2011) Ply-based composite modeling with the new* ELEMENT_SHELL_COMPOSITE keyword

Halim NFHA, Ascroft H, Barnes S (2017) Analysis of tool wear, cutting force, surface roughness and machining temperature during finishing operation of ultrasonic assisted milling (UAM) of carbon fibre reinforced plastic (CFRP). Procedia Eng 184:185–191. doi:10.1016/j.proeng.2017.04.084

Ha SJ, Kim KB, Yang JK, Cho MW (2017) Influence of cutting temperature on carbon fiber-reinforced plastic composites in high-speed machining. J Mech Sci Technol 31(4):1861–1867. doi:10.1007/s12206-017-0333-8

Mishnaevsky L (2007) Mesoscale level in the mechanics of materials. Wiley, pp 13–36. doi:10.1002/9780470513170.ch2

Burns LA, Mouritz AP, Pook D, Feih S (2012) Strength improvement to composite T-joints under bending through bio-inspired design. Compos A: Appl Sci Manuf 43(11):1971–1980. doi:10.1016/j.compositesa.2012.06.017

Sato N, Hojo M, Nishikawa M (2015) Intralaminar fatigue crack growth properties of conventional and interlayer toughened CFRP laminate under mode I loading. Compos A: Appl Sci Manuf 68:202–211. doi:10.1016/j.compositesa.2014.09.031

Jones RM (1999) Mechanics of composite materials, 2nd edn. Taylor and Francis, Blacksburg

Roos R, Kress G, Ermanni P (2007) A post-processing method for interlaminar normal stresses in doubly curved laminates. Compos Struct 81(3):463–470. doi:10.1016/j.compstruct.2006.09.016

ANSYS (2013) ANSYS Composite preppost user’s guide Release 15.0 edn. Canonsburg

Rakesh PK, Sharma V, Singh I, Kumar D (2011) Delamination in fiber reinforced plastics: a finite element approach. Engineering 03(05):549–549

Hashin Z (1980) Failure criteria for unidirectional fiber composites. J Appl Mech 47(2):329–334. doi:10.1115/1.3153664

Camanho PP, Dávila CG (2002) Mixed-mode decohesion finite elements for the simulation of delamination in composite materials. NASA/TM-2002-211737

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67(9):1939–1945. doi:10.1016/j.compscitech.2006.10.009

Tsao CC, Kuo KL, Hsu IC (2012) Evaluation of a novel approach to a delamination factor after drilling composite laminates using a core–saw drill. Int J Adv Manuf Technol 59 (5):617–622. doi:10.1007/s00170-011-3532-y

Capello E (2004) Workpiece damping and its effect on delamination damage in drilling thin composite laminates. J Mater Process Technol 148(2):186–195

Yuan S, Zhang C, Amin M, Fan H, Liu M (2015) Development of a cutting force prediction model based on brittle fracture for carbon fiber reinforced polymers for rotary ultrasonic drilling. Int J Adv Manuf Technol 81(5):1223–1231. doi:10.1007/s00170-015-7269-x

Shan C, Dang J, Yan J, Zhang X (2017) Three-dimensional numerical simulation for drilling of 2.5d carbon/carbon composites. Int J Adv Manuf Technol. doi:10.1007/s00170-017-0653-y

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-wandi, S., Ding, S. & Mo, J. An approach to evaluate delamination factor when drilling carbon fiber-reinforced plastics using different drill geometries: experiment and finite element study. Int J Adv Manuf Technol 93, 4043–4061 (2017). https://doi.org/10.1007/s00170-017-0880-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0880-2