Conclusions

The work reported represents only the beginning of a line of research into steelmaking processes which will be continued. Development of a better understanding of these mechanisms will prove valuable in designing future processes as well as in developing better understanding and control of present processes. The conclusions which may be drawn at this stage are:

-

1.

Surface areas for the carbon-oxygen reaction in the BOF process are extremely large and at the height of refining in commercial converters may reach values in the order of 2000 sq. ft. per ton.

-

2.

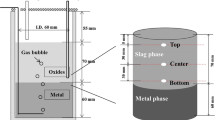

In BOF refining, the furnace contains a large volume fraction of gas-slag-metal emulsion. The quantity of metal within this emulsion expressed as a percentage of the total metallic charge may reach 30%, or more. This represents a significant fraction of the total metal within the system which is not present in the bulk metallic phase.

-

3.

The emulsified metal has a substantially lower carbon concentration than the average of all the liquid metal within the vessel.

-

4.

In the BOF process, decarburization does not take place principally from the metallic bath, but rather from emulsified metal. At the height of refining, most decarburization occurs within the slag-metal emulsion. Over the entire blowing period, as much as two-thirds of the starting carbon is removed from metal emulsified in the slag rather than from the bulk metallic phase.

-

5.

Carbon diffusion is not the rate-controlling mechanism for decarburization, except during the last few minutes of the blow when the bulk carbon concentration is below 0.35%.

-

6.

Finally, it is now clear that the existence of relatively stable slag-metal emulsions is a key technical factor in the commercial success of the BOF process. These emulsions provide high interphase surface areas for mass transfer and are thus the vehicle for extremely high reaction rates. It is probable that slag-metal emulsions also also played an important role in the Bessemer process and in pneumatic non-ferrous processes such as the copper converter, even though this factor was not fully understood at the time of the development and practice of these processes.

Similar content being viewed by others

References

H. W. Meyer and J. A. Glasgow, “Development and Operation of BOF Dynamic Control”, AISI, 1966.

E. Aukrust, M. M. Fischer, and W. F. Porter, “BOF Dynamic Control”, Operating Metallurgy Conference, AIME, Philadelphia, December 5, 1966.

E. Plockinger and M. Wahlster, “Metallurgy of Oxygen Top Blowing Process”, Stahl und Eisen, 80, 1960, pp. 407–416.

W. G. Davenport, A. V. Bradshaw, and F. D. Richardson, “Behavior of Spherical Cap Bubbles in Liquid Metals”, Journal of Iron & Steel Institute, Vol. 205, October 1967, pp. 1034–1042.

W. F. Porter, F. D. Richardson, and K. N. Subramanian, “Some Studies of Mass Transfer Across Interfaces Agitated by Bubbles”, Heat and Mass Transfer in Process Metallurgy, Institution of Mining & Metallurgy, London, 1967.

K. N. Subramanian and F. D. Richardson—Private Communication.

B. M. Larson, “A New Look at the Nature of the Open Hearth Process”, Special Report N.O.H.C., AIME, No. 1, 1956.

J. Crank, “The Mathematics of Diffusion”, Oxford Press, London, 1956.

K. Schwerdtfeger, “Diffusion of Oxygen and Nitrogen in Liquid Iron”. Trans. AIME, 239, 1967, pp. 134–137.

J. Szekely and M. R. Todd, “A Note on the Reaction Mechanism of Carbon Oxidation in Oxygen Steelmaking Processes”, Trans. AIME, 239, 1967, pp. 1664–1666.

K. Li, D. A. Dukelow, and G. C. Smith, “Decarburization in Iron-Carbon System by Oxygen Top Blowing”, Trans. AIME, 230, 1964, pp. 71–76.

H. W. Meyer, E. Aukrust, and W. F. Porter, “Process Analysis and Control of Basic Oxygen Furnaces”, Heat and Mass Transfer in Process Metallurgy, Institution of Mining & Metallurgy, London, 1967.

H. W. Meyer, D. A. Dukelow, and M. M. Fischer, “BOF Static and Dynamic Control Considerations”, Journal of Metals, 16, 1964, pp. 501–507.

P. Kozakevitch, G. Urbain, B. Denizot, H. Marette, “Study of Basic Phosphate Slag Foams”, Int. Congress Oxygen Steelmaking, Le Touquet, Sept. 1963, IRSID.

Author information

Authors and Affiliations

Additional information

The following article is a slightly revised form of a paper delivered on February 27, 1968 at the AIME Annual Meeting in New York City.

Rights and permissions

About this article

Cite this article

Meyer, H.W., Porter, W.F., Smith, G.C. et al. Slag-Metal Emulsions and Their Importance in BOF Steelmaking. JOM 20, 35–42 (1968). https://doi.org/10.1007/BF03378731

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03378731