Abstract

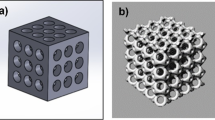

This paper is the second in a two-part series on mold filling analysis for lost foam casting of aluminum. Part I (published in the IJMC Volume 2, Issue 3, Summer 2008) describes the analysis method, assumptions, and governing equations, and this paper (Part II) discusses applications of the analysis to a variety of pattern shapes that exhibit different types of mold filling behavior, many of which are unique to lost foam casting. The first example compares mold filling in a horizontal foam strip filled from the side with filling in the same strip oriented vertically and filled from the top or bottom. The results illustrate the unusual effect that pattern orientation and thickness have on metal fluidity in lost foam casting. The second example, a rectangular plate filled through a single inlet located on a top, bottom or side edge, illustrates how different modes of foam decomposition can interact during the filling of a single pattern. The mold filling sequence turns out to be dramatically different depending on inlet location and pattern thickness. The third example is a generic box pattern that has long been used at GM and elsewhere to study the lost foam process. This pattern is filled from the back through three separate inlets, creating two merging flow fronts inside the cavity. The likelihood of these metal fronts enclosing foam between them when they come together is explored by examining the concavity of their flow front profiles. For several cases considered in this paper, the results of the analysis are compared with X-ray and neutron radiography images taken during actual mold filling.

Similar content being viewed by others

References

Barone, M. R. and Caulk, D. A., “Analysis of Mold Filling in Lost Foam Casting of Aluminum: Part I — Method,” International Journal of Metal Casting, vol. 2, pp. 29–43 (2008).

Barone, M. R. and Caulk, D. A., “A Pattern Decomposition Model for Lost Foam Casting of Aluminum: Part I — Contact Mode,” AFS Transactions, vol. 114 (2006).

Tsai, H. L., and Chen, T. S., “Modeling of Evaporative Pattern Process, Part I: Metal Flow and Heat Transfer During the Filling Stage,” AFS Transactions, vol. 96, pp 881–890 (1988).

Shivkumar, S., “Modeling of temperature losses in liquid metal during casting formation in expendable pattern casting process,” Materials Science and Technology, vol. 10, pp 986–992 (1994).

Sun, W. L., Littleton, H. E., and Bates, C. E., “Real-Time X-Ray Investigations on Lost Foam Mold Filling,” AFS Transactions, vol. 110, pp 1347–1356 (2002).

Caulk, D. A., “A Pattern Decomposition Model for Lost Foam Casting of Aluminum: Part II — Gap Mode,” AFS Transactions, vol. 114 (2006).

Molibog, T. V., and Littleton, H., “Degradation of Expanded Polystyrene Patterns,” AFS Transactions, vol. 110, pp 1483–1496 (2002).

Bennett, S., Ramsay, C. W., and Askeland, D. R., “Temperature Gradients During Fill and Solidification of Al LFCs,” AFS Transactions, vol. 106, pp 357–363 (1998).

Tseng, C.-H., and Askeland, D. R., “A Study of Selected Process Parameters for the Evaporative Pattern Casting Process,” AFS Transactions, vol. 99, pp 455–464 (1991).

Shivkumar, S., “Casting Characteristics of Aluminum Alloys in the EPC Process,” AFS Transactions, vol. 101, pp 513–518, (1993).

Fu, J., Tsai, H.-L., and Askeland, D. R., “Mold Filling in Thin Section Castings Produced by the EPC Process,” AFS Transactions, vol. 103, pp 817–828 (1995).

Sun, Y., Tsai, H. L., and Askeland, D. R., “Influence of Pattern Geometry and Other Process Parameters on Mold Filling in Aluminum EPC Process,” AFS Transactions, vol. 103, pp 651–662 (1995).

Pan, E. N., and Liao, K. Y., “Study on Flowability of EPC A356 Al Alloy,” AFS Transactions, vol. 106, pp 233–242 (1998).

Pan, E. N., and Liao, K. Y., “Filling Behavior of EPC A356 Alloy Castings,” AFS Transactions, vol. 107, pp 751–760 (1999).

Zhao, Q., Burke, J. T., Gustafson, T. W., “Foam Removal Mechanism in Aluminum Lost Foam Casting,” AFS Transactions, vol. 110, pp 1399–1414 (2002).

Goettsch, D. D., Companion CD in Lost Foam Casting Made Simple, F. Sonnenberg, ed., AFS, Schaumburg, IL, 2007.

Caulk, D. A., “A Foam Melting Model for Lost Foam Casting of Aluminum,” International Journal of Heat and Mass Transfer, vol. 49, pp 2124–2136 (2006).

Caulk, D. A., “A Pattern Decomposition Model for Lost Foam Casting of Aluminum: Part IV-Engulf Mode,” AFS Transactions, vol. 115 (2007).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Caulk, D. Analysis of Mold Filling in Lost Foam Casting of Aluminum: Part II-Example Applications. Inter Metalcast 3, 7–25 (2009). https://doi.org/10.1007/BF03355438

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355438