Abstract

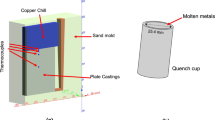

Computer controlled thermal heating and cooling curve cycles of the W319 (Al-7.5Si-3.5Cu-0.3Fe) and the WA328 (Al-9Si-lCu-0.3Fe) alloy samples were studied in this work. Both alloys contain residual levels of Sr (∼ 20 ppm max) and are processed with no grain refiner. From the cooling curve portion of the thermal cycle the characteristic temperature points that represent phase nucleation and growth are established. Once characteristic temperatures in the alloy samples are known, strategic quench points can be chosen to reveal the evolving mushy state using metallographic examination. In particular the growth kinetics of primary α-Al dendrites in quenched and unquenched alloys are studied and discussed in this work. In addition, growth modes for the Al-Si eutectic lamellae and polyhedral Si particles were also observed from quenched test samples during and post the Al-Si nucleation temperature event.

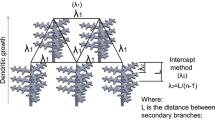

For each microstructure examined (quenched and unquenched test samples) the Secondary Dendrite Arm Spacing (λ2), Dendrite Cell Size (DCSz), and Microhardness (25g/15s μHV) of coarse dendrites were measured. For the test samples quenched at the beginning of the Al-Si eutectic nucleation event Image Analysis techniques were used to assess the area fraction of dendrites. This result, found for both alloys, was compared to fraction solid determined from conventional thermal analysis methods which have software capabilities for fraction solid calculation. The purpose for the analysis in this article stems from previous research on cast component testing using the WA328 and W319 alloys. The WA328 alloy has lower porosity but contains almost the same λ2 values as the W319 alloy. The lower porosity enhanced fatigue performance.

Similar content being viewed by others

References

G. F. Bourcier, J. Dickinson, J. Tessandori & D. Schiffer, Aluminum Recycling Casebook, The Aluminum Association Inc., pp. 56 (1985).

J. E. Gruzleski & B. M. Closset, The Treatment of Liquid Aluminum-Silicon Alloys, American Foundry Society, Inc., 1990, 256pp (1990).

Aluminum Casting Technology, Revised by J. L. Jorstad, W. M. Rasmussen, Edited by D. L. Zalensas, 2nd Ed., American Foundry Society, Inc., pp 201 (1993).

R.I. Mackay & J.H. Sokolowski, “Alloying with Silicon and Copper in Aluminum Alloys”, Journal Materials Science Forum, Vols. 539–546, pp. 392–397 (March 2007).

L. Bäckerud, G. Chai, J. Tamminen, “Solidification Characteristics of Aluminum Alloys” Vol. 2, Foundry Alloys, AFS/Skanaluminum, pp. 255, (1990).

J. M. Boileau, J. W. Zindel, & J. E. Allison, “The Effect of Solidification Time on The Mechanical Properties of A356-T6 Aluminum Alloys,” SAE, Paper # 970019, SAE Warrendale, PA, (1997).

P. N. Crepeau, “Effect of Iron in Al-Si Alloys: A Critical Review”, AFS Transactions, Vol. 103, pp. 361–366, (1995).

G. Gustafsson, T. Thorvaldsson, & G. L. Dunlop, “The Influence of Fe and Cr on the Microstructure of Cast AI-Si-Mg Alloys”, Metallurgical Transactions A, Vol. 17A, pp. 45–52, (1986).

L. Bäckerud, E. Krol and T. Tamminen, “Solidification Characteristics of Aluminum Alloys”, Volume 1: “Wrought Alloys”, AFS/Skanaluminum, pp. 156, (1996).

M. H. Mulazimoglu, N. Tenekedjiev, B. M. Closset, J. E. Gruzleski, “Microstructure and Thermal Analysis of Strontium Treated Aluminum-Silicon Alloys”, American Foundry Society, Inc., pp. 116, (1997).

M. C. Flemings, T. Z. Kattamis & B. P. Bardes, “Dendrite Arm Spacing in Aluminum Alloys”, AFS Transactions, Vol. 99, pp. 501–506, (1991).

P. Kumar & J. L. Gaindhar, “DAS, Solidification Time and Mechanical Properties of Al-11%Si Alloy V-Processed Castings”, AFS Transactions, Vol. 105, pp. 635–638, (1997).

T. Campanella, C. Charbon & M. Rappaz, “Microstructural Development in Copper-Based Alloys during Solidification”, 7thEuropean Conference on Advanced Materials and Processes, EUROMAT 2001, Rimini, Italy, pp. 456–466, 2001.

J. E. Gruzleski, “Microstructure Development during Metalcasting”, American Foundry Society, Inc., pp. 236, (2000).

Ø. Nielsen & S. O. Olsen, “Assessment of Dendrite Morphology by Quenching from the Mushy State”, AFS Transactions, Vol. 110, pp. 567–572, (2002).

G. Figuerdo, Y. Sumartha, M.C. Flemings, “Measurement and Calculation of Fraction Solid in Quenched Semi-solid Melts of Rheocast Aluminum Alloy A357”, Light Metals, pp. 1103–1106, (1998).

O. Pompe & M. Rettenmayr, “Microstructual Changes During Quenching”, Journal of Crystal Growth, vol. 192, pp. 300–306, (1998).

S. Chen, C.C. Huang, “Solidification Curves of Al-Cu, Al-Mg and Al-Cu-Mg Alloys”, Acta Materialia, vol. 44, pp. 1955–1965, (1996).

S. Takamori and D. Stefanescu, “Evaluation of Coherency, Dendrite Envelope and Internal Fraction Solid for Al-Cu Alloys”, Proceedings of the 4thDecennial International Conference on Solidification Processing, Sheffield, pp. 217–221, (1997).

J. W. Zindel, G. Goldewski & D. Donlon, “Microstructural Evolution of an 319 Alloy During Solidification”, Modeling of Casting, Welding & Advanced Solidification Processes VII, TMS, San Diego, June 7–12, (1998).

A. K. Dahle, K. Nogita, J. W. Zindel, S. D. McDonald and L.M. Hogan, “Eutectic Nucleation and Growth in Hypoeutectic Al-Si Alloys at Different Strontium Levels”, Metallurgical & Materials Transactions A, Vol. 32A No 4, pp. 949–960, (2001).

E. Talaat & H. Fredriksson, “Solidification Mechanism of Unmodified and Strontium Modified Al-Si Alloys”, Materials Transactions, Vol. 41, No 4, pp. 507–515, (2000).

M. H. Mulazimoglu, A. Zaluska, J. E. Gruzleski & F. Paray, “Electron Microscope Study of Al-Fe-Si Intermetallics in 6xxx.x Series Aluminum Alloys”, Metallurgical & Materials Transactions A, Vol. 27A, pp. 929–936, 1996.

A. Savitzky and M. Golay, “Smoothing and Differentiation of Data by Simplified Least Squares Procedures”, Analytical Chemistry, v. 36, No 8, pp 1627–1639, (1964).

R. Mackay, M. Djurdjevic and J. H. Sokolowski, “The Effect of Cooling Rate on the Fraction Solid of the Metallurgical Reactions in the 319 Alloy”, AFS Transactions, Vol. 108, pp. 521–529, (2000).

M. B. Djurdjevic, W. Kasprzak, C. A. Kierkus, W. T. Kierkus and J. H. Sokolowski, “Quantification of Cu Enriched Phases in Synthetic 3XX Aluminum Alloys Using Thermal Anaylsis”, AFS Transactions, Vol. 103, pp. 455–467, (2001).

W. T. Kierkus and J. H. Sokolowski, “Recent Advances in CCA: A New Method of Determining ‘Baseline’ Equation”, AFS Transactions, v. 66, pp. 161–167, (1999).

L. Arnberg, L. Bäckerud and G. Chai, “Solidification Characteristics of Aluminum Alloys”, Volume 3: “Dendrite Coherency”, AFS/Skanaluminum, pp. 247, (1996).

L. Bäckerud, E. Krol and T. Tamminen, “Solidification Characteristics of Aluminum Alloys”, Volume 1: “Wrought Alloys”, AFS/Skanaluminum, pp. 156, (1996).

L. Bäckerud, G. Chai, J. Tamminen, “Solidification Characteristics of Aluminum Alloys” Vol. 2, Foundry Alloys, AFS/Skanaluminum, pp. 255, (1990).

M. H. Mulazimoglu, N. Tenekedjiev, B. M. Closset, J. E. Gruzleski, “Microstructure and Thermal Analysis of Strontium Treated Aluminum-Silicon Alloys”, American Foundry Society, Inc., pp. 116, (1997).

W. Kurz, and D. J. Fisher, Fundamentals of Solidification, Trans Tech Publications, UK-USA, pp. 299, (1986).

J. E. Gruzleski, “Microstructure Development during Metalcasting”, American Foundry Society, Inc., pp. 236, (2000).

R.I. Mackay & J. H. Sokolowski, “Alloying with Silicon and Copper in Aluminum Alloys”, Journal Materials Science Forum, Vols. 539–546, pp. 392–397 (March 2007).

G. A. Edwards, G. K. Sigworth, C. H. Cáceres, D. H. St. John, & J. Barresi, “Microporosity Formation in Al-Si-Cu-Mg Casting Alloys”, AFS Transactions, Vol. 105, pp. 809–818, (1997).

ASM Handbook Vol. 3: Alloy Phase Diagrams, The Materials Information Society, (1992).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mackay, R., Sokolowski, J. Experimental Observations of Dendrite Coarsening & Al-Si Eutectic Growth in Progressively Quenched Structures of Al-Si-Cu Casting Alloys. Inter Metalcast 2, 57–75 (2008). https://doi.org/10.1007/BF03355428

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355428