Abstract

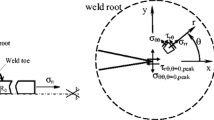

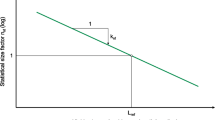

Several fatigue failures are initiating from the root of non-penetrating welds, which are widely applied in several industrial sectors. The structural optimization and reduction of weld material increase the danger of root cracking. The fatigue assessment during design is mainly based on the nominal, structural hot-spot or notch stress approach. These approaches are only partly applicable to weld roots, give rough estimates such as the nominal stress approach or over-conservative life estimation such as occasionally the notch stress approach when keyhole notches are modelled. An alternative assessment is possible with the crack propagation approach assuming the non-welded root gap and a short crack at the weld toe as initial cracks. A new approach is the notch stress intensity approach (N-SIF approach) which is able to assess the fatigue life of V-shaped notches at weld toes as well as crack-like notches at weld roots using the strain energy density around the notch. Both approaches are applied to different joints where toe and root failures are probable. The results are compared with a previous analysis using the notch stress approach. Fatigue test results are also available for a comparison which allows to draw conclusions with respect to the approaches for an appropriate fatigue strength assessment.

Similar content being viewed by others

Abbreviations

- a:

-

weld throat thickness

- a:

-

initial crack length

- ac :

-

critical crack length

- C:

-

material constant

- da/dN:

-

crack propagation rate

- E:

-

modulus of elasticity

- E′:

-

modified modulus of elasticity

- e1, e2 :

-

parameters for dependency from α

- Kc :

-

critical stress intensity factor

- K1, K2 :

-

stress intensity factor for Mode I and Mode II loading

- ℓ:

-

length

- λ1, λ2 :

-

eigenvalues of the stress field for K1 and K2 modes

- m:

-

slope exponent of S-N curve

- m:

-

material constant (in Paris equation)

- N:

-

number of load cycles

- Ps :

-

probability of survival

- R:

-

stress ratio (lower stress/upper stress)

- ReH :

-

yield stress

- R0 :

-

control radius

- R*:

-

enlarged control radius

- rref :

-

reference radius ref. to notch stress

- t:

-

plate thickness

- Tσ :

-

scatter index ref. to fatigue strength for Ps= 10 and 90%

- W:

-

elastic strain energy density

- α:

-

half opening angle of V-notch

- Δa:

-

crack increment

- ΔK:

-

range of stress intensity factor

- ΔKth :

-

threshold range of stress intensity factor

- Δσc :

-

characteristic fatigue strength

- Δσeq :

-

equivalent stress range

- Δσn :

-

nominal stress range

- ΔσT :

-

range of T-stress (parallel to slit)

- ΔW:

-

range of elastic strain energy density

- ΔWT :

-

range of elastic strain energy density due to T-stress

- v:

-

Poisson’s number

- σ:

-

stress

References

Niemi E., Fricke W. and Maddox S.: Fatigue analysis of welded components — Designer’s guide to the structural hot-spot stress approach, Woodhead Publishing, Cambridge, 2006.

Hobbacher A.: Recommendations for fatigue design of welded joints and components, Doc. IIW-1823, WRC Bulletin 520, Welding Research Council, Inc., New York, 2009.

Radaj D., Sonsino C.M. and Fricke W.: Recent developments in local concepts of fatigue assessment of welded joints, International Journal of Fatigue, 2009, vol. 31, no. 1, pp. 2–11.

Radaj D., Sonsino C.M. and Fricke W.: Fatigue assessment of welded joints by local approaches, Woodhead Publishing (2nd Edition), Cambridge, 2006.

Lazzarin T. and Tovo R.: A notch intensity factor approach to the stress analysis of welds, Fatigue & fracture of engineering materials & structures, 1998, vol. 21, no. 9, pp. 1089–1103.

Livieri P. and Lazzarin P.: Fatigue strength of steel and aluminium welded joints based on generalised stress intensity factors and local strain energy values, International Journal of Fracture, 2005, vol. 133, no. 3, pp. 247–276.

Lazzarin P., Berto F., Gomez F.J. and Zappalorto M.: Some advantages derived from the use of the strain energy density over a control volume in fatigue strength assessments of welded joints, International Journal of Fatigue, 2008, vol. 30, no. 8, pp. 1345–1357.

Paris P.C. and Erdogan F.: A critical analysis of crack propagation laws, Trans. ASME, Journal of Basic Engineering, 1963, Series D, vol. 85, no. 4, pp. 528–534.

Maddox S.J.: Assessing the significance of flaws in welds subject to fatigue, Welding Journal, 1974, Res. Suppl., vol. 53, no. 9, pp. 401s–409s.

Petershagen H.: A comparison of two different approaches for the fatigue strength assessment of cruciform joints, IIW Doc. XIII-1410-91, 1991.

Fricke W. and Feltz O.: Fatigue tests and numerical analyses of partial-load and full-load carrying fillet welds at cover plates and lap joints, Doc. IIW-2080, Welding in the World, 2010, vol. 54, no. 7/8, pp. R225–R233.

Williams M.: Stress singularities resulting from various boundary conditions in angular corners of plates in extension, Journal of Applied Mechanics, (ASME), 1952, vol. 19, no. 4, pp. 526–528.

Boukharouba T., Tamine T., Nui L., Chehimi C. and Pluvinage G.: The use of notch stress intensity factor as a fatigue crack initiation parameter, Engineering Fracture Mechanics, 1995, vol. 52, no. 3, pp. 503–512.

Lazzarin P. and Zambardi R.: A finite-volume-energy-based approach to predict the static and fatigue behaviour of components with sharp V-shaped notches, International Journal of Fracture, 2001, vol. 112, no. 3, pp. 275–298.

Williams M.: On the stress distribution at the base of a stationary crack, Journal of Applied Mechanics, 1957, vol. 24, no. 1, pp. 109–114.

BS 7608: Code of practice for fatigue assessment of steel structures, British Standards Institution, London, 1993.

Franc2D/L: http://www.cfg.cornell.edu/software/franc2d_casca.htm, 2004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fischer, C., Feltz, O., Fricke, W. et al. Application of the Notch Stress Intensity and Crack Propagation Approaches to weld toe and root fatigue. Weld World 55, 30–39 (2011). https://doi.org/10.1007/BF03321305

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321305