Abstract

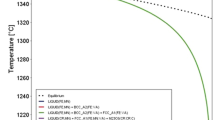

Hot cracking is a major problem in the welding of austenitic stainless steels (SS), particularly the fully austenitic grades. A group of alloys of high nitrogen stainless steel is being developed for structural components of the Indian Fast Reactor programme. Studying the hot cracking behaviour of this nitrogen-enhanced austenitic stainless steel is an important consideration during welding, as this material solidifies without any residual delta-ferrite in the primary austenitic mode. Nitrogen has potent effects on the solidification microstructure; hence, it is expected to have a strong influence on the hot cracking behaviour. Both Varestraint and hot ductility tests were used to evaluate its solidification and liquation cracking susceptibility. Different heats of this material were investigated, which included fully austenitic (high nitrogen stainless steels) containing 0.07–0.22 wt. (%) nitrogen. Varestraint tests were carried out on these alloys using specimens of 3 mm thickness at four strain levels between 0.5 and 4.0%. The Brittleness Temperature Range (BTR) was also evaluated from these tests. The Varestraint test results showed that the solidification cracking susceptibility is higher for 0.22 wt. (%) steel and the liquation (HAZ) crack significantly increases with increasing nitrogen content. Hot ductility tests were conducted on these alloys using a thermomechanical simulator and the Nil Strength Temperature (NST), Nil Ductility Temperature (NDT) and Ductility Recovery Temperature (DRT) were determined. The hot ductility test results showed that the nil ductility range (NDR), the difference between NST and DRT of the nitrogen-enhanced steel containing 0.22 % N, is higher (50 °C) than that of the alloys containing 0.07 % N (40 °C) and 0.14 % N (30 °C), indicating high susceptibility of the 0.22 % N alloy to liquation cracking. This paper presents and discusses the role of high nitrogen content on hot cracking susceptibility of this class of steels using Varestraint and hot ductility tests.

Similar content being viewed by others

References

Mannan S.L., Chetal S.C., Raj Baldev and Bhoje S.B.: Selection of materials for prototype fast breeder reactor, Transactions of the Indian Institute of Metals, 2003, vol. 56, no. 2, pp. 155–178.

Ganesan V., Mathew M.D. and Sankara Rao K.B.: Influence of nitrogen on tensile properties of 316LN SS, Materials Science and Technology, 2009, vol. 25, no. 5, pp. 614–618.

Folkhard E.: Welding metallurgy of stainless steels, Springer Verlag, New York, 1998.

Brooks J.A. and Thompson A.W.: Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds, International Materials Reviews, 1991, vol. 36, no. 1, pp. 16–44.

Robinson J.L. and Scott M.H.: Liquation cracking during the welding of austenitic stainless steels and nickel alloys, Philosophical Transactions of the Royal Society A, London, 1980, vol. 295, no. 1413, pp. 105–117.

Masumoto I., Takami K. and Kutsuna M.: Hot cracking of austenitic stainless steel weld metal, Journal of the Japan Welding Society, 1972, vol. 41, pp. 1306–1314.

Garner A.: Pitting corrosion of high alloys stainless steel weldments in oxidising environments, Welding Journal, 1983, vol. 62, no. 2, pp. 27s–34s

Gill T.P.S., Vijayalakshmi M., Gnanamoorthy J.B. and Padmanabhan K.A.: Transformation of delta-ferrite during the post weld heat treatment of type 316L stainless steel weld metal, Welding Journal, 1986, vol. 66, no. 5, pp. 122s–126s

Cieslak M.J., Ritter A.M. and Savage W.F.: Solidification cracking and analytical electron microscopy of austenitic stainless steel weld metals, Welding Journal, 1982, vol. 61, no. 1, pp. 1s–8s

Matsuda F., Nakagawa H., Katayama S. and Arata Y: Solidification crack susceptibility of in weld metals of fully austenitic stainless steels (report VIII) — Effect of nitrogen on cracking in SUS 304 weld metal, Transactions of Joining and Welding Research Institute, 1983, vol. 12, no. 1, pp. 89–95.

Ogawa T, Suzuki K. and Zaizen T.: The weldability of nitrogen-containing austenitic stainless steel, Welding Journal, 1984, vol. 63, no. 7, pp. 213s–223s

Kujanpää V.P.: Effects of steel type and impurities in solidification cracking of austenitic stainless steel welds, Met. Constr., 1985, vol. 117, no. 1, pp. 40R–46R

Lundin C.D., Lee C.H. and Qiao C.Y.P.: Group sponsored study — Weldability and hot ductility behaviour of nuclear grade austenitic stainless steels, Final Report, University of Tennessee, Knoxville, USA, 1988.

Lundin C.D., Lingenfelter A., Grotke G., Lessman G. and Mathews S.: The Varestraint Test, Welding Research Council Bulletin, 1982, no. 280.

Wilken K. and Kleistner H.: The classification and evaluation of hot crack test for weldments, Doc. IIW-1000–88, Welding in the World, 1990, vol. 28, no. 7/8, pp. 37–48

Shankar V., Gill T.P.S., Mannan S.L. and Sundaresan S.: Solidification cracking in austenitic stainless steel welds, Sadhana, June/August 2003, vol. 28, Parts 3 and 4, pp. 359–382.

Lin W., Lippold J.C. and Baeslack W.A.: An investigation of HAZ liquation cracking susceptibility, Part I: Development of a method for quantification, Welding Journal, 1994, vol. 72, no. 4, pp. 135s–153s

Lundin C.D., Qiao C.Y.P. and Lee C.H.: Standardisation of Gleeble hot ductility testing, Part I: Historical Review, Weldability of Materials, ASM International, Materials Park, Ohio, 1990, pp. 1–8.

Lippold J.C. and Kotecki D.J.: Welding Metallurgy and Weldability of Stainless Steels (Ist edition), John Wilely & Sons, USA 2005.

Musech H.: Welding of material grade TP347 modified, Nuclear Engineering and Design, 1985, vol. 85, no. 2, pp. 155–161.

Blind D., Weber G. and Kussmaul K.: Liquation cracking and chromium depletion in austenitic welds of light water reactors, Proc. SMiRT15 (PCS-2), The University of Tokyo, Aug 23–25, 1999, pp. 205–213.

Kujanpää V.P., David S.A. and White C.L.: Formation of hot cracks in austenitic stainless steel welds- solidification cracking, Welding Journal, 1986, vol. 65, no. 8, pp. 203s–212s

Kujanpää V.P., Suutala N., Takalo T. and Moisio T.: Correlation between solidification cracking and micro-structure in austenitic-ferritic stainless steel welds, Welding Research International, 1979, vol. 9, no. 2, pp. 55–76.

Nishimoto K. and Mori H.: Hot cracking susceptibility in laser weld metal of high nitrogen stainless steels, Science and Technology of Advance Materials, 2004, vol. 5, no. 1–2, pp. 231–240

Lundin C.D., Lee C.H. and Menon R.: Hot ductility and weldability of free machining austenitic stainless steel, Welding Journal, 1988, vol. 67, no. 6, pp. 119s–130s

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Srinivasan, G., Divya, M., Albert, S.K. et al. Study of Hot Cracking Behaviour of Nitrogen-Enhanced Austenitic Stainless Steels using Varestraint and Hot Ductility Tests. Weld World 54, R322–R332 (2010). https://doi.org/10.1007/BF03266746

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266746