Abstract

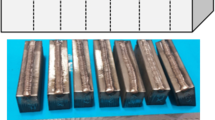

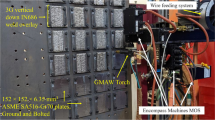

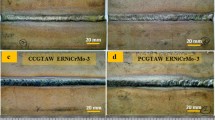

Nickel superalloys are considered extremely difficult to weld and repair because of their susceptibility to heat-affected zone (HAZ) and weld metal cracking during fabrication, postweld heat treatment (PWHT) and subsequent operation. The weldability and repairability by TIG of annealed Alloy 718 and aged Waspaloy was investigated. Alloy 718 was investigated as this alloy provides a reference aerospace grade material. Forced cooling was applied during welding to control the temperature gradient, as this is known to be able to alleviate welding residual stress in aluminium alloys and stainless steels. The level of welding residual stress is one of the main factors controlling the weldability of nickel alloys, and minimising the amount of residual stress is beneficial to cracking resistance. An investigation into the shroud sealing of single crystal nickel superalloy CMSX-10 was also performed by TIG and electro-spark deposition (ESD) techniques with no preheat applied. Application of forced cooling aged Waspaloy resulted in the reduction or elimination of HAZ microfissures due to the reduction of thermal strain, distortion and stresses. Forced cooling during welding of Alloy 718 resulted in a substantial reduction of distortion and buckling. Weld metal and HAZ hardness were almost completely recovered after PWHT of Waspaloy deposits and SEM examination showed that γ’-phase re-formed in the HAZ during PWHT. CMSX-10 showed a high susceptibility to weld metal and HAZ cracking during standard TIG welding employing a Mar-M247 consumable. HAZ cracking was associated with recrystallisation of the parent material. No cracking or microfissures were found in the HAZ of ESD deposits on single crystal CMSX-10 alloy. No recrystallisation occurred in the parent material associated with Mar-M247 deposits produced by ESD.

Similar content being viewed by others

References

Gregori A.: A survey of welding and repairing of nickel superalloys for gas turbines, TWI Core Research Programme 774/2003, August 2003.

Woo I., Nishimoto K., Tanaka K., Shirai M.: Characteristic of heat affected zone cracking in Inconel 718 cast alloy, Study of weldability of Inconel 718 cast alloy (1st Report), Welding International, 2000, Vol. 14, pp. 365–374.

Owczarski W.A., Duvall D.S., Sullivan C.P.: A model for heat affected zone cracking in nickel-base superalloys, Welding Journal, 1966, Vol. 45, pp. 145s–155s.

Duvall D.S., Owczarski W.A.: Studies of postweld heat-treatment cracking in nickel-base alloys, Welding Journal, 1969, Vol. 3, pp. 10s–22s.

David S.A., Babu S.S., Vitek J.M.: Weldability and microstructure development in nickel-base superalloys, Mathematical modelling of weld phenomena 4, Publ. IOM, London, UK, 1998, ISBN 1 86125 060 6, pp. 269–289.

Gaumann M., Henry S., Cleton F., Wagniere J.D., Kurz W.: Epitaxial laser metal forming: analysis of microstructure formation, Material Science and Engineering A, 1999, Vol. A271, pp. 232–241.

Foster M., Updegrove K.: Welding superalloy articles, US Patent No. US 6333484, Chromalloy Gas Turbine Corp, December 2001.

Scudamore R.J., Allen J.: Laser-deposition of nickel-based superalloys, Waspaloy — A preliminary study, TWI Core Research Programme 794/2004, March 2004.

Guan Q., Legatt R.H., Brown K.W.: Low stress non-distortion (LSND) TIG welding of thin-walled structural elements, TWI Core Research Programme 374/1988, July 1988.

Bagshaw N., Olden E., Bertaso D.: Numerical simulation and experimental validation of low stress no distortion (LSND) welding in 304 stainless steel welding, TWI Core Research Programme 780/2003, November 2003.

Melton G.B., Bertaso D., Gregori A.: TWI Report, to be published.

Miglietti W.M., Benson J., Blum F., Harms P., Penne-father R.: Variable polarity GTAW of SMP14 single crystal superalloy Part I: effects on microstructure and tensile properties, Proc. Conf. “Materials Solutions 97 on Joining and Repair of Gas Turbine Components”, 15–18 September 1997, Indianapolis, USA, Publ. ASM, Materials Park, OH, USA, 1997 pp. 79–93.

Reignier C.: Preliminary evaluation of electrospark deposition process for repair of worn components, TWI Core Research Programme 699/2000, March 2000.

Haafkens M.H., Matthey J.H.G.: A new approach to the weldability of nickel-base as-cast and powder metallurgy superalloys, Welding Journal, No. 11 November 1982, Vol. 61, pp. 25–30.

Nakao Y.: Study on reheat cracking of Ni-base super-alloy, Waspaloy, Transactions of the Japan Welding Society, April 1988, Vol. 19, No. 1, pp. 66–74.

Erickson G.L: Single crystal nickel-based superalloy, US Patent No. US5366695, Cannon-Muskegon Corporation, November 1994.

Erickson G.L.: The development and application of CMSX-10, Proc. Conf. “Superalloys 1996”, 1996, Champion PA, USA Publ. TMS, Warrendale, USA, 1996, pp. 35–44.

Broomfield R., Ford D., Bhangu H., Thomas M., Frasier D., et al.: Development and turbine engine performance of three advanced rhenium containing superalloys for single crystal and directionally solidified blades and vanes, Cannon-Muskegon Technical Publication CM-012, December 1996, Publ. Cannon-Muskegon Corporation, Muskegon, MI, USA.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gregori, A., Bertaso, D. Welding and Deposition of Nickel Superalloys 718, Waspaloy and Single Crystal Alloy CMSX-10. Weld World 51, 34–47 (2007). https://doi.org/10.1007/BF03266607

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266607