Abstract

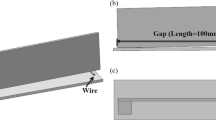

Vastly different microstructures are formed in 304LN austenitic and Fecralloy® ferritic stainless steel joints brazed with Ni-15Cr-1.4B-7.25Si (MBF-51) and Ni-19Cr-1.5B-7.3Si (MBF-50), filler metals, respectively. These joints were cut from an industrial heat exchanger and a metallic catalyst support that were subjected to a short optimal brazing cycle in a vacuum furnace. A detailed description is given of the composition and morphology of phases evolved in these brazements, as a result of complex metallurgical reactions between the base and filler metals. A new metallurgical reaction was discovered between Fe-20Cr-5Al Fecralloy base metal (BM) having b.c.c. crystal lattice, and the Ni and B from MBF-50 (Ni-19Cr-1.5B-7.25Si) brazing filler metal (FM). This reaction resulted in the precipitation of fine, regularly distributed Nix (Al)y particles in the base metal matrix phase, thus strengthening Fecralloy brazements. The microstructure discovered in this work is remarkably similar to that of conventional precipitation-hardened, heat resistant alloys. Therefore, these joints can withstand years of service in the brutal environment observed in automotive exhaust pipes.

Similar content being viewed by others

References

Rabinkin A., Wenski E., Ribaudo A.: Brazing stainless steel using a new MBF- series of Ni-Cr-B-Si amorphous foil, Weld. J., 1998, 77, No. 2, pp. 66s–75s.

Rabinkin A.: Optimization of brazing technology, structural integrity, and performance of multi- channeled, three dimensional metallic structures, Proceedings of the International Brazing and Soldering Conference, 2000, pp. 437–444, Albuquerque.

Rabinkin A.: Overview: Brazing with (NiCoCr)-B-Si amorphous brazing FMs: Alloys, processing, joint structure, properties, applications, Sci. Tech. Welding and Joining, 2004, 9, No. 3, pp. 181–199.

Rabinkin A.: Brazing with amorphous foil preforms, Adv. Mat. Proc., 2001, 159, No. 6, pp. 65–67.

Heikinheimo L., Miglietti W., Kipnis J., Leone E., Rabinkin A.: Brazing of Co- and Ni- based superalloys using new amorphous brazing filler metals, in LOT01, DVS, Aahen, 2001, pp. 468–475.

Karlson L., Norden H.: Non-equilibrium grain boundary segregation of boron in austenitic stainless steel — IV. Precipitation Behavior and distribution of elements at grain boundaries, Acta Metal., 1988, 36, No. 1, pp. 35–48.

Karlson L., Norden H., Odelius H.: Non-equilibrium grain boundary segregation of boron in austenitic stainless steel — I. Large Scale segregation behavior, Acta Metal., 1988, 36, No. 1, pp. 1–12.

Villars P., Prince A., Okamoto H.: Handbook of Ternary alloy phase diagrams, ASM, 3, 1995, p. 3156 and p. 3538.

Kubaschewski O., Alcock C.B.: Metallurgical thermochemistry, Univ. Toronto, 5th Ed., 1978, pp. 300–301.

Villars P., Prince A., Okamoto H.: Handbook of Ternary alloy phase diagrams, ASM, 3, 1995, pp. 3105–3118.

Wang W., Zhang S., He X.: Diffusion of boron in alloys, Acta Metal. & Mat., 1995, 43, pp. 1693–1699.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Leone, E.A., Rabinkin, A. & Sarna, B. Microstructure of Thin-Gauge Austenitic and Ferritic Stainless Steel Joints Brazed using Metglas® Amorphous Foil. Weld World 50, 3–15 (2006). https://doi.org/10.1007/BF03266509

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266509