Abstract

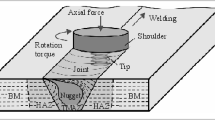

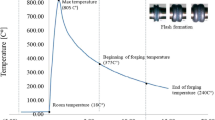

For ordinary arc welding processes such as MIG, welding deformation, residual stress and inherent strain are important factors to control the reliability of weldments. Friction stir welding (FSW) is a new welding method, especially for light metals. The distortion of FSW is reportedly small but reasons can not be determined in detail. This paper deals with thermal cycles and inherent strains which create both residual stresses and welding deformations, in order to make clear effective factors that lower apparent strains on FSW than on MIG. Inherent strains were measured by using the layer removal technique. Thermal cycles and maximum temperature rise were measured by type K thermocouples. It is concluded from experimental data that the main cause lowering apparent strain in FSW is the compressive load that makes tensile plastic strain in weldments. The second cause is that the heat input is smaller than in ordinary arc welding processes.

Similar content being viewed by others

References

Midling, O.T., Morley, E.J., Sandvik, A., Friction stir welding, European Patent Application 959 078 88.2.

Thomas, W.M., Nicholas, E.D., Needham, J.G., Murch, M.G., Temple-Smith, P., Dawes, C.J., Improvements relating to friction welding, European Patent Specification 0615 480 B1.

Chao, Y.J. and Qi, X., Heat Transfer and Thermo-Mechanical Analysis of Friction Stir Joining of AA6061-T6 Plates, 1st International Symposium on Friction Stir Welding, 14–16, June, 1999, USA.

Watanabe, M. and Satoh, K., Welding Strength and Application, (1965), Asakura.

Thomas, W. M., Threadgill, P.L. and Nicholas, E.D., Feasibility of friction stir welding steel, Science and Technology of Welding and Joining, 4 (1999), 365–372.

Fukuda, K., General Theory of Measuring Residual Stresses and New Measuring Method of 3-Dimensional Residual Stresses, (in Japanese) 1979, Ph. D. thesis of Osaka University.

Fukuda, K., Kim, Y., Akiyama, T. and Terasaki, T., Method for Estimating Residual Stress Produced in Sprayed Coating and Substrate by means of the Concept of Inherent Strain, (in Japanese), Thermal Spray, 27 (1990), 124–131.

Terasaki T., Akiyama, T. and Ishimura, T., New Method for Estimating Residual Stresses in Pipe Made by Surfacing Weld, ASME J. Eng. Ind., 117 (1995), 365–371.

Chen, J., Terasaki, T., Akiyama, T. and Kishitake, K., New Concept of Equivalent Inherent Strain for Measuring Axisymmetric Residual Stresses, ASME J. Manuf. Sci. and Eng., 122 (2000), 304–309.

Terasaki, T., Yamasaki, M. and Akiyama, T., Cause of Residual Stress Produced by Friction Stir Welding, (in Japanese), Joining and Materials Processing for Light Structures MP-267–2000 (2000), Japan Welding Society.

Terasaki, T., Akiyama, T. and Yoshimura N., A Study on Residual Stress in Evaporation Coating Film, (in Japanese), Jpn. Soc. Mech. Eng., 59 A (1993), 2694–2701.

Terasaki, T., Chen, J., Akiyama, T. and Kishitake, K., Non-Destructive Method for Estimating Residual Stress Distributin in Component due to Shot Peening, JSME International Jour., Series A, 42 (1999), 216–223.

Aluminum handbook, The Japan Institute of Light Metals (1994).

Terasaki, T. and Fukuya, M., Distribution of Inherent Strain Generated in Butt Joint, (in Japanese), Jpn. Soc. Mech. Eng., 66 A (2000), 1233–1238.

Sato, Y., Kokawa, H., Enomoto, M. and Jogan, S., Microstructural Evolution of 6063 Aluminum during Friction Stir Welding, Metal. Mater. Trans. A, 30 (1999), 2429–2437.

Satoh, K., A Note On Heat Conduction By Moving Heat Source (in Japanese), J. of Japan Welding Society, 36 (1967), 154–159.

Rosenthal, D., The theory of Moving Sources of Heat and Its Application to Metal Treatments, ASME, 68 (1946), 849–866.

Wells, A.A., Heat Flow in Welding, W.J., 31 (1952), 263s–267s.

Terasaki, T., Matsuyama, K. and Kamikihara, H., Experiment and Predictive Equation of Heat Input Generated in Plate by Thermal Cutting Process, IIW(2000), IE-314–00.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Terasaki, T., Akiyama, T. Mechanical Behaviour of Joints in FSW: Residual Stress, Inherent Strain and Heat Input Generated by Friction Stir Welding. Weld World 47, 24–31 (2003). https://doi.org/10.1007/BF03266405

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266405