Abstract

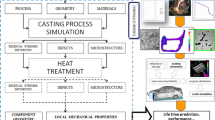

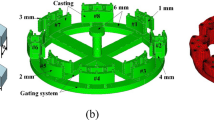

A major roadblock preventing the widespread use of casting simulation technology is the intensive effort required by a highly skilled-professional to construct a finite-element model. To address this situation, this article proposes an integrated-model construction procedure that reduces model construction time for a typical aeropropulsion component from two weeks to two days. It also describes another step toward the accurate and practical prediction of the coating process through coupled heat transfer, fluid flow, and stress calculation.

Similar content being viewed by others

References

K.O. Yu et al., “Solidification Modeling of Single Crystal Investment Casting,” AFS Transactions (1990).

J.S. Tu and R.K. Foran, “The Application of Defect Maps in the Process Modeling of Single-Crystal Investment Casting,” JOM, 44(6) (1992), p. 26.

A.M. Hines and J.S. Tu, “Modeling of Fluid Flow and Heat Transfer in the Solidification of Superalloy Investment Castings,” Modeling of Casting, Welding, and Advanced Solidification Processes VI (Warrendale, PA, TMS, 1993), p. 461.

J.S. Tu, D.M. Olinger, and A.M. Hines, “Computer-Aided Development of an Investment Casting Process,” JOM, 45 (10) (1993), p. 29.

B.A. Mueller and P. Monaghan, “Overview of the Investment Casting Cooperative Arrangement,” JOM (September 1994), p. 17.

M. McLean, Directionally Solidified Materials for High Temperature Service (London: the Metals Society, 1983), p. 26.

Author information

Authors and Affiliations

Additional information

Editor's Note

The results presented here are based on research funded by the U.S. Advanced Research Projects Agency (ARPA) through the Investment Casting Cooperative Arrangement (ICC A). The ICCA is a consortium of five companies: General Electric Aircraft Engines, Pratt & Whitney, Howmet Corporation, PCC, and UES. In addition to these five member companies, a number of research institutes are participating members of the program. For more information on the ICCA, refer to Reference 5. A richly linked World Wide Web version of this article with color versions of the figures has been prepared for TMS Online. To access this version of the document contact http: / /www. tms.org/pubs/journals/JOM/9510/Tu-9510.html.

Rights and permissions

About this article

Cite this article

Tu, J.S., Kelly Foran, R., Hines, A.M. et al. An Integrated procedure for modeling investment castings. JOM 47, 64–68 (1995). https://doi.org/10.1007/BF03221290

Issue Date:

DOI: https://doi.org/10.1007/BF03221290