Abstract

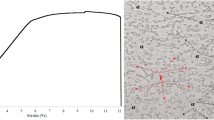

AA6061 aluminium alloy (Al−Mg−Si alloy) has gathered wide acceptance in the fabrication of food processing equipment, chemical containers, passenger cars, road tankers, and railway transport systems. The preferred process for welding these aluminium alloys is frequently Gas Tungsten Arc (GTA) welding due to its comparatively easy applicability and lower cost. In the case of single pass GTA welding of thinner sections of this alloy, the pulsed current has been found beneficial due to its advantages over the conventional continuous current processes. The use of pulsed current parameters has been found to improve the mechanical properties of the welds compared to those of continuous current welds of this alloy due to grain refinement occurring in the fusion zone. In this investigation, an attempt has been made to develop a mathematical model to predict the fusion zone grain diameter incorporating pulsed current welding parameters. Statistical tools such as design of experiments, analysis of variance, and regression analysis are used to develop the mathematical model. The developed model can be effectively used to predict the fusion grain diameter at a 95% confidence level for the given pulsed current parameters. The effect of pulsed current GTA welding parameters on the fusion zone grain diameter of AA 6061 aluminium alloy welds is reported in this paper.

Similar content being viewed by others

References

R. P. Simpson,Weld. J. 56, 67 (1977).

J. G. Garland,Met. Constr. 6, 121 (1974).

R. K. Prasad,Proc. Natl. Conf. on Recent Advances in Materials Processing, p. 176–196, Annamalai Nagar, India (2001).

V. P. Ravi,Welding in the World 35, 214 (1995).

A. A. Gokhale, A. A. Tzavaras, H. D. Brody, and G. M. Ecer,Proc. Conf. on Grain Refinement in Castings and Welds, p. 223–247, TMS-AIME, St. Louis, MO (1982).

R. G. Madhusudhan, A. A. Gokhale, and R. K. Prasad,J. Mater. Sci. 32, 4117 (1997).

H. Yamamoto,Weld. Int. 7, 456 (1993).

G. Madhusudhan Reddy, A. A. Gokhale, and K. Prasad Rao,J. Mater. Sci. Tech. 14, 61 (1998).

V. Ravisankar and V. Balasubramanian,Proc. Int. Conf. on IMPLAST, p. 224–232, New Delhi, India (2003).

G. E. P. Box, W. H. Hunter, and J. S. Hunter,Statistics for experiments, John Wiley (1978).

D. C. Montgomery,Design and Analysis of Experiments, John Wiley & Sons, New York (1991).

J. Ravindra and R. S. Parmar,Met. Constr. 19, 45 (1987).

George F. Vander Voort,Metallography: Principles and Practices, McGraw Hill, New York (1972).

I. Miller, J. Freund, and R. Johnson,Probability and Statistics for Engineers, Prentice of Hall of India Pvt. Ltd., New Delhi (1999).

S. Kou and Y. Le,Weld. J. 65, 305 (1986).

A. F. Norman, K. Hyde, F. Costello, S. Thompson, S. Birley, and P. B. Pragnell,Mater. Sci. Eng. A 354, 188 (2003).

T. Shinoda, Y. Ueno, and I. Masumoto,Trans. Jpn. Weld. Soc. 21, 18 (1990).

Reddy G. Madhusudhan,Proc. ISTE Summer School on Recent Developments in Materials Joining, Annamalai University (2001).

D. C. Lin, T. S. Wang, and T. S. Srivatsan,Mater. Sci. Eng. A 335, p. 304 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, T.S., Balasubramanian, V., Babu, S. et al. Effect of pulsed current GTA welding parameters on the fusion zone microstructure of AA 6061 aluminium alloy. Met. Mater. Int. 13, 345–351 (2007). https://doi.org/10.1007/BF03027892

Issue Date:

DOI: https://doi.org/10.1007/BF03027892