Abstract

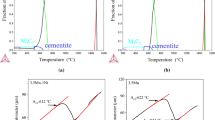

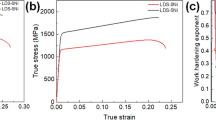

In our previous studies, sintered and heat-treated alloy steels (Fe−6Ni−0.5Mo−0.4C (mass%)) produced by a MIM process showed excellent mechanical properties of 2000 MPa tensile strength and 5% elongation. This was attributed to the solid solution strengthening and the mezzo-heterogenous microstruture, which consisted of martensite or retained austenite (Ni and Mo rich phases) surrounded by a network of tempered martensite. This study has been performed to clarify the effect of Mo on the mezzo-heterogeneous microstructure and the mechanical properties of MIM processed and sintered alloy steels (Fe−6Ni−0.4C) with varying Mo content (0.5–2 mass%). The tensile properties of the heat-treated steels with added 2 mass% Mo were lower than those of the steels with added 0.5 mass% Mo. The reduction in the tensile properties, particularly the appearance of large pores formed at the original location of Mo power through the transient liquid phase formation and the low hardness of the matrix, was due to the low sintered density. By using mechanically milled fine Ni and Mo powders, the heat-treated steel (Fe−6Ni−2Mo−0.4C) showed excellent properties, including tensile strength of 1800 MPa and ductility of 2.2% elongation.

Similar content being viewed by others

References

K. Baba, T. Honda, and H. Miura,J. Jpn. Soc. Powder & Powder Metall. 44, 443 (1997).

M. Matsuda and H. Miura,J. Jpn. Soc. Powder & Powder Metall. 47, 681 (2000).

M. Matsuda and H. Miura,Proc. of 2000 Powder Metallurgy World Congress (eds., K. Kosuge and H. Nagai), p. 20, Jpn. Soc. Powder & Powder Metall., Kyoto (2000).

M. Matsuda and H. Miura,J. Jpn. Soc. Powder & Powder Metall. 48, 451 (2001).

H. Danninger,Powder Metall. Int. 20, 7 (1998).

H. Danninger, T. Kara, M. Ruhnow, and H. Ullrich,Mikrochimica Acta 2, 219 (1990).

Y. Hanatake, K. Majima, and H. Mitani,J. Jpn. Inst. Met. 40, 1010 (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation made in the symposium “The 3rd KIM-JIM Joint Symposium on Advanced Powder Materials”, held at Korea University, Seoul, Korea, October 26–27, 2001 under auspices of The Korean Institute of Metals and Materials and The Japan Institute of Metals.

Rights and permissions

About this article

Cite this article

Matsuda, M., Miura, H. Mechanical properties of injection molded Fe-6% Ni-0.4% C steels with varying Mo contents of 0.5 to 2%. Met. Mater. Int. 9, 537–542 (2003). https://doi.org/10.1007/BF03027252

Issue Date:

DOI: https://doi.org/10.1007/BF03027252