Abstract

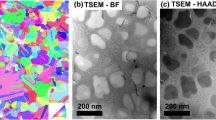

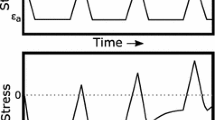

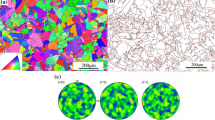

Fatigue crack propagation in nickel-base superalloys at low and intermediate temperatures occurs predominantly in the Stage I mode, along {111} slip planes. Cracking normally starts at an external surface and the Stage I fracture surface has a cleavage appearance. Both of these factors indicate that the environment may play an important role in this mode of propagation. To assess the role of environment in Stage I fracture and to determine the mechanism of failure, fatigue tests were run in air and vacuum on single crystals of low-carbon MAR-M200. The fatigue life at room temperature is significantly greater in vacuum than in air, and the improvement in life increases as the stress range is reduced. Fatigue crack propagation in specimens tested in air and in vacuum is entirely in the Stage I mode, but only the specimens tested at low stress ranges in air have a cleavage appearance. In vacuum and at high applied stress levels in air, fracture surfaces have a matte appearance with fewer fracture steps and river lines. At high magnifications, a dimpled structure is observed on these fracture surfaces. The fatigue life in air can be attributed to a faster rate of crack growth resulting from oxygen adsorption at the crack tip. A model for Stage I fatigue crack propagation in planar slip materials is presented which is an extension of the Griffith-Orowan criterion to cases where localized cleavage occurs at a crack tip in fatigue.

Similar content being viewed by others

References

H. J. Gough and D. G. Sopwith:J. Inst. Metals, 1932, vol. 49, pp. 92–112.

H. J. Gough and D. G. Sopwith:J. Inst. Metals, 1935, vol. 56, p. 55.

H. J. Gough and D. G. Sopwith:J. Inst. Metals, 1946, vol. 72, p. 415.

J. M. Jacisin:Trans. TMS-AIME, 1967, vol. 239, p. 821.

W. Engelmaier:Trans. TMS-AIME, 1968, vol. 242, p. 1713.

N. J. Wadsworth and J. Hutchings:Phil. Mag., 1958, vol. 3, p. 1154.

N. Thompson, N. Wadsworth, and N. Louat:Phil. Mag., 1956, vol. 1, p. 113.

R. M. N. Pelloux:Trans. ASM, 1969, vol. 62, p. 281.

H. Shen, S. E. Podlaseck, and I. R. Kramer:Acta Met., 1966, vol. 14, p. 341.

M. R. Achter:Fatigue Crack Propagation, Spec. Tech. Publ. 415, p. 181, ASTM, Philadelphia, 1967.

G. J. Danek, Jr., H. H. Smith, and M. R. Achter:Proc. Am. Soc. Testing Mater., 1961, vol. 224, p. 1115.

C. Laird and G. C. Smith:Phil. Mag., 1963, vol. 8, p. 1945.

M. Gell and G. R. Leverant:Trans. TMS-AIME, 1968, vol. 242, p. 1869.

M. Gell and G. R. Leverant:Acta Met., 1968, vol. 16, p. 553.

M. Gell, G. R. Leverant, and C. H. Wells:Achievement of High Fatigue Resistance in Metals and Alloys, Amer. Soc. Testing Mater., Spec. Tech. Publ. 467, p. 113, 1970.

S. M. Copley and B. H. Kear:Trans. TMS-AIME, 1967, vol. 239, p. 984.

M. R. Achter:Scripta Met., 1968, vol. 2, p. 525.

J. K. Tien and R. P. Gamble:Met. Trans., 1971, in press.

F. E. Fujita:Fracture of Solids, TMS Conf., vol. 20, p. 678. Interscience Publ., New York, 1963.

D. J. Duquette, M. Gell, and J. W. Piteo:Met. Trans., 1970, vol. 1, p. 3107.

M. B. McNeil and J. C. Grosskreutz:Phil. Mag., 1967, vol. 16, p. 1115.

A. Kelly, W. R. Tyson, and A. H. Cottrell:Phil. Mag., 1967, vol. 15, p. 567.

A. R. C. Westwood, C. M. Preece and M. H. Kamdar:Trans. ASM, 1967, vol. 60, p. 723.

C. A. Stubbington and P. J. E. Forsyth:Metallurgia, 1966, vol. 74, p. 15.

K. R. L. Thompson and J. V. Craig:Met. Trans., 1970, vol. 1, p. 1047.

D. I. Golland and P. L. James:Met. Sci. J., 1970, vol. 4, p. 113.

M. Gell and J. B. Vandersande: Advanced Matl. Res. and Dev. Lab. Pratt & Whitney Aircraft, Middletown, Conn., unpublished research.

P. Beardmore and P.H. Thornton: Ford Sci. Lab., Ford Motor Co., Dearborn, Michigan, private communication.

Author information

Authors and Affiliations

Additional information

D. J. DUQUETTE, formerly with Pratt & Whitney Aircraft, Middletown, Conn.

Materials Engineering and Research Laboratory, Pratt & Whitney Aircraft

Rights and permissions

About this article

Cite this article

Duquette, D.J., Gell, M. The effect of environment on the mechanism of Stage I fatigue fracture. Metall Trans 2, 1325–1331 (1971). https://doi.org/10.1007/BF02913355

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02913355