Abstract

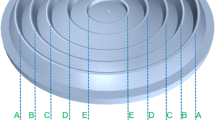

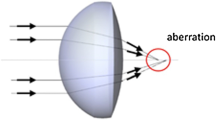

For the purpose of reducing the volumetric shrinkage and volumetric shrinkage variation, the process in injection molding of aspheric plastic lens was simulated, and several process parameters which include holding pressure, melt temperature, mold temperature, fill time, holding pressure time and cooling time were optimized by using an orthogonal experimental design method. Finally, the optimum process parameters and the influence degree of process parameters on the average volumetric shrinkage and the volumetric shrinkage variation are obtained.

Similar content being viewed by others

References

Amit Kumar, P S Ghoshdastidar, M K Muju. Computer Smulation of Transport Processes during Injection Mold-filling and Optimization of the Molding Conditions.Journal of Materials Processing Technology, 2002, 120:438–449

K M B Jansen. Effect of Processing Conditions on Shrinkage in Injection Molding.Polymer Engineering and Science, 1998, 38(5):838–846

T C Chang. Shrinkage Behavior and Optimization of Injection Molded Parts Studied by the Taguchi Method.Polymer Engineering and Science, 2001, 41(5):703–710

Ming-Chih Huang, Ching-Chih Tai. The Effective Factors in the Warpage Problem of an Injection-molded Part with a Thin Shell Feature.Journal of Materials Processing Technology, 2001, 110:1–9

Xuehong Lu, Lau Soo Khim. A Statistical Experimental Study of the Injection Molding of Optical Lenses.Journal of Materials Processing Technology, 2000, 113:189–195

Shih-Hsing Chang, Jiun-Ren Hwang, Ji-Liang Dong. Optimization of the Injection Molding Process of Short Glass Fiber Reinforced Polycarbonate Composites Using Grey Relational Analysis.Journal of Materials Processing Technology, 2000, 97:186–193

R S Chen, H H Lee, C Y Yu. Application of Taguchi’s Method on the Optional Process Design of an Injection Molded PC/PBT Automobile Bumper.Composite Structures, 1997, 39 (3–4):209–214

Xi Chen, Furong Gao. A Study of Packing Profile on Injection Molded Part Quality.Materials Science and Engineering, 2003, 358:205–213

L W Seow, C Lam. Optimizing Flow in Plastic Injection Molding.Journal of Materials Processing Technology, 1997, 72: 333–341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jialing, W., Pengfei, W. The simulation and optimization of aspheric plastic lens injection molding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 20, 86–89 (2005). https://doi.org/10.1007/BF02838498

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02838498