Abstract

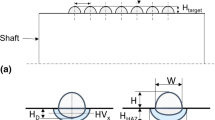

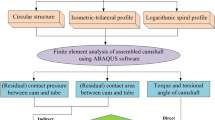

Assembled camshafts offer an attractive manufacturing alternative over conventional methods to meet the demand for high performance camshafts at reduced costs. The manufacture of camshafts has traditionally involved the casting, forging, or machining of a rough blank which was further machined to the finished cam geometry. A new method will be discussed in which individual near-net shaped components are precision assembled onto a tube to pregrind tolerances. Completion of this camshaft only requires a finish grinding operation. The individual components are manufactured by casting, precision warm or cold forging, high speed turning, or powder metal consolidation. The process allows for material selection flexibility to optimize materials for all components with respect to performance and cost. In addition to the inherent advantages of the assembled camshaft, the process typically results in cost advantages over conventionally processed camshafts.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Horvat, G.L., Surface, S.C. Assembled camshafts for automotive engines. J. Mater. Shaping Technol. 7, 133–136 (1989). https://doi.org/10.1007/BF02834742

Issue Date:

DOI: https://doi.org/10.1007/BF02834742