Abstract

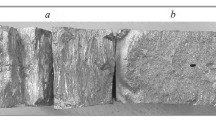

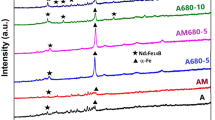

The preparation of Nd-Fe-B permanent magnets by rapid solidification processing is described. The initial rapid quench is typically carried out by melt spinning; magnetic hardening can be achieved either by quenching directly from the melt or by annealing an overquenched precursor. In both instances, optimum permanent magnet properties are associated with the formation of a uniform, finely crystalline (<100 nm diam) microstructure consisting primarily of the Nd2Fe14B phase. Consolidation of the rapidly solidified material into isotropic magnets can be achieved by conventional cold compaction of the powder with a resin binder or by hot pressing to full density. Owing to the extremely fine grain size, orientation of the isotropic ribbons by grinding followed by magnetization would be extremely difficult. Crystallographic anisotropy can be achieved, however, by hot deformation. Alignment occurs entirely by thermomechanical means with rotation of the easy crystallographic direction normal to the direction of plastic flow. Energy products to 40 MGOe have been achieved by this technique. Properties of the various types of magnets prepared from this rapidly solidified material are presented as is microstructural data for the material at key points in the manufacturing process.

Similar content being viewed by others

References

J.J. Croat,Appl. Phys. Lett. 37, 1096 (1980).

N.C. Koon and B.N. Das,Appl. Phys. Lett. 39, 840 (1981); N.C. Koon, C.M. Williams, and B.N. Das.,J. Appl. Phys. 52, 2535 (1981).

J.J. Croat,Appl. Phys. Lett. 39, 357 (1981);J. Appl. Phys. 53, 3161 (1982).

J.J. Croat and J.F. Herbst,J. Appl. Phys. 53, 2404 (1982).

B.N. Das and N.C. Koon,Metall. Trans. 14A, 953 (1983).

G.C. Hadjipanayis, R.C. Hazelton, K. Lawless, and D.J. Sellmyer,Appl. Phys. Lett. 43, 797 (1983).

J.J. Croat, J.F. Herbst, R.W. Lee, and F.E. Pinkerton,Appl. Phys. Lett. 44, 148 (1984);J. Appl. Phys., 55, 2078 (1984).

M. Saqawa, S. Fujimura, N. Togawa, H. Hamamota, and Y. Matsuura,J. Appl. Phys., 55, 2083 (1984).

J.F. Herbst, J.J. Croat, F.E. Pinkerton, and W.B. Yelon,Phys. Rev. B29, 4176 (1984).

D. Givord, H.S. Li, and J.M. Moreau,Solid State Commun, 50, 497 (1984).

K.S.V.L. Narasimhan,J. Appl. Phys., 57, 4081 (1985).

H.F. Braun, M. Pelizzone, and K. Yvon, Proc. 7th International Conf. on Solid Compounds of Transition Elements, Grenoble, Vol. II B11 (1982).

R.K. Mishra,J. Mag. Magn. Mat., to be published.

Y.L. Chen, IEEE, Trans. Magn. MAG-21 1967, 1985.

R.W. Lee,Appl. Phys. Lett. 46 (8), 790 (1985).

R.K. Mishra and R.W. Lee,Appl. Phys. Lett., 48 (11), 733 (1986).

F.E. Pinkerton and D.J. Van Wingerden,J. of Applied Phys., to be published.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Croat, J.J. Neodymium—iron—boron permanent magnets prepared by rapid solidification. J. Mater. Eng. 10, 7–13 (1988). https://doi.org/10.1007/BF02834109

Issue Date:

DOI: https://doi.org/10.1007/BF02834109