Abstract

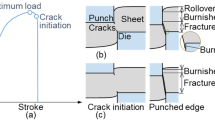

A previously described tensile strip test which simulates the stretching of sheet over a punch corner radius in a typical draw die was used to compare frictional effects in different sheet materials. Various grades of steel including galvanized samples were tested as well as soft and age-hardening aluminum alloy sheets. The measured friction coefficients varied over a wide range and the experiments illustrate how the straining process over the punch is influenced by both the stress-strain curve of the sheet and its friction characteristics.

Similar content being viewed by others

References

H. Nine:Mechanics of Sheet Metal Forming, D. P. Kristinen and N.M. Wang, eds., Plenum Press, New York, NY, 1978, p. 179.

J. L. Duncan, B. S. Shabel and J. Gerbase Filho: “A Tensile Strip Test for Evaluating Friction in Sheet Metal Forming,”SAE Technical Paper No. 780391, 1978.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, XJ., Duncan, J.L. & Devenpeck, M.L. Punch friction tests for sheet metal forming. J. Applied Metalworking 3, 3–11 (1983). https://doi.org/10.1007/BF02833871

Issue Date:

DOI: https://doi.org/10.1007/BF02833871