Abstract

The influence of an oxidizing molten nitrate salt environment (60 pct NaNO3-40 pct KNO3) on the mechanical properties of INCOLOY® Alloy 800 has been examined through a series of slow strain rate tensile tests. Fracture strain, reduction in area and ultimate tensile strength were monitored as parameters indicative of alloy susceptibility to environmental degradation.

For strain rates between 2 ×10 −7 sec−1 and 3.34 ×10 −5 sec−1 no appreciable loss in ductility as measured by the above parameters was observed at 600 ‡C relative to control specimens tested in air at the same strain rates and temperature. Similarly, the load-bearing capability of the alloy was unaffected by exposure to the environment.

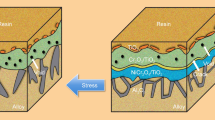

The structure of the oxide film formed by contact of the alloy with the molten salt was affected by the imposed continuous deformation. Deformation resulted in an oxide which was thicker than that formed on undeformed salt-exposed surfaces. While this difference in oxide thickness was a measurable phenomenon, the increased rate of oxidation was not great enough to alter appreciably alloy mechanical behavior in the salt compared to that measured in air over the time limits considered. In addition, fine subsurface cracks were observed in those oxides formed on deformed surfaces.

Similar content being viewed by others

References

R. W. Mar and J. C. Swearengen: “Materials Issues in Solar Thermal Energy Systems,”Solar Energy Materials, 1981, vol. 5, pp. 37–53.

D. A. Nissen: “Thermophysical Properties of the Equimolar Mixture NaNO3-KNO3 from 300 to 600 ‡C,” SAND80-8040, Sandia National Laboratories, Livermore, CA.

R. W. Carling: Proceedings 3rd International Symposium on Molten Salts, Electrochem. Soc, Pennington, NJ, 1980, p. 485.

C. M. Kramer: Ph.D. Thesis, University of California, Davis, CA, 1980.

A. P. Arvia, J.J. Podesta and R.C.V. Piatti:Electrochem. Acta, 1972, vol. 17, p. 33.

I. D. Dirmeik:Corrosion NACE, 1969, vol. 25, p. 180.

S. L. Marchiano and A. J. Arvia:Electrochem. Acta, 1972, vol. 17, p. 861.

A. Baraka, A.I. Abdel-Rohman and A.A. El Hosary:Br. Corr. J., 1976, vol. 11, no. 1, p. 44.

C. M. Kramer, W. H. Smyrl and W. B. Estill:J. Mater. for E. Systems, 1980, vol. 1, p. 59.

R. W. Bradshaw: “Corrosion of 304SS by Molten NaNO3-KNO3 in a Thermal Convection Loop,” SAND80-8856, Sandia National Laboratories, Livermore, CA, 1980.

S.H. Goods:J. Mater. for E. Systems, 1980, vol. 3, p. 43.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Goods, S.H. The effect of a molten nitrate salt environment on the mechanical properties of INCOLOY alloy 800. JMES 5, 28–35 (1983). https://doi.org/10.1007/BF02833504

Issue Date:

DOI: https://doi.org/10.1007/BF02833504