Abstract

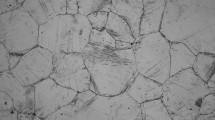

Microstructure of precipitates produced by annealing ion implanted surfaces have been investigated in the Al2O3-ZrO2 system and both microhardness and indentation fracture toughness have been measured for correlation with microstructure. Air annealing of 190 keV high dose implants of Al+ in yttriastabilized zirconia and Zr+ in AI2O3 have resulted in A12O3 and ZrO2 precipitates, respectively, as would be expected from phase equilibria. However, annealing schedules drastically alter precipitate microstructure (i.e., crystallite size, morphology, orientation), and changes in microstructure have produced significant variation of surface mechanical properties. Crystallization of the ZrO2 films on AI2O3 was observable by conventional XRD. The precipitated ZrO2 was in the monoclinic structure if the grain size was large or in the tetragonal state if grain size was small. Being able to produce tetragonal ZrO2 particles in A12O3 surfaces suggests the possibility of transformation toughening and strengthening.

Similar content being viewed by others

References

R. S. Roth, T. Negas, and L. P. Cook:Phase Diagram for Ceramists, Figures 4377, 4378, & 5437, The American Ceramic Soc, Columbus, OH, 1981, vol. IV.

Science and Technology of Zirconia, A. H. Heuer and L. W. Hobbs, eds., The American Ceramic Society, Columbus, OH, 1981.

Science and Technology of Zirconia II, N. Claussen, M. Ruhle, and A. H. Hener, eds., The American Ceramic Society, Columbus, OH, 1984.

C. J. McHargue and C. S. Yust:J. Am. Ceram. Soc, 1984, vol. 67 (2), p. 117.

P. J. Burnett and T. F. Page: inIon Implantation and Ion Beam Processing of Materials, G. K. Hubler, O. W. Holland, C.R. Clayton, and C.W. White, eds., MRS Proceedings, V27, North Holland, Amsterdam, 1984, p. 401.

T. Hioki, A. Itoh, S. Noda, H. Doi, J. Kawamoto, and O. Kamigaito:Nuclear Instruments and Methods in Physics Research, B7/8, North Holland, Amsterdam, 1985, pp. 521–25.

K.O. Legg, J.K. Cochran, H. F. Solnick-Legg, and X.L. Mann:Nuclear Instruments and Methods in Physics Research, B7/8, North Holland, Amsterdam, 1985, pp. 535–40.

G. R. Anstis, P. Chantikul, B. R. Lauen, and D. B. Marshall:J. Am. Ceram. Soc., 1981, vol. 64 (9), pp. 533–38.

H.J. Kandil, J.D. Greiner, and J.F. Smith:J. Am. Ceram. Soc., 1984, vol. 65 (5), pp. 341–46.

R.H. Doremus:Glass Science, John Wiley and Sons, New York, NY, 1973.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cochran, J.K., Pope, S.G., Legg, K.O. et al. Ion implanted precipitate microstructure and mechanical properties of ceramic surfaces. JMES 8, 121–127 (1986). https://doi.org/10.1007/BF02833336

Issue Date:

DOI: https://doi.org/10.1007/BF02833336