Abstract

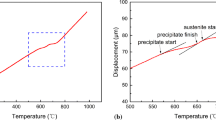

A technique has been developed for controlling the austenitic grain size of 18 pct Ni maraging steels by thermal treatment alone. This treatment has been applied to two different grades, 250 and 300, of maraging steel, and a large grain size, ASTM 2, was reduced to ASTM 7 in both cases. The process of grain size refinement requires thermal cycling from a temperature belowM f to a temperature considerably above the austenitizing temperature. The minimum austenitic grain size attainable depends on the prior strain in the material as well as the thermal treatment. While significant grain size refinement can be attained by one cycle to the proper temperature, the attainment of the minimum uniform grain size requires several cycles. The effects of austenitic grain size on tensile properties have been investigated both at room temperature and at elevated temperatures. The prior austenitic grain size has a small but measurable effect on the mechanical behavior of aged material at room temperature. The austenitic grain size has a significant effect on the ultimate tensile strength at 1600°F.

Similar content being viewed by others

References

A. Goldberg:ASM Trans. Quart, 1968, vol. 55, p. 26.

A. Goldberg and D. G. O’Connor:Nature, 1967, vol. 213, p. 170.

G. E. Pellissier:Eng. Fracture Mechanics, 1968, vol. 1, p. 55.

G. W. Tuffnell, D. L. Pasquine, and J. H. Olson:ASM Trans. Quart., 1966, vol. 59, p. 769.

A. M. Hall:Metals Handbook, vol. 2, 8th ed., p. 255, Am. Soc. Metals, Novelty, Ohio.

A. M. Hall, R. C. Simon, and D. P. Moon:DMIC Processes and Properties Handbook, p. I-1, Battelle Memorial Institute, Columbus, Ohio, 1968.

J. A. Roberson and A. M. Adair:Trans. TMS-AIME, 1969, vol. 245, p. 1937.

S. Floreen and R. F. Decker:ASM Trans. Quart., 1962, vol. 55, p. 518.

D. T. Peters and C. R. Cupp:Trans. TMS-AIME, 1966, vol. 236, p. 1420.

D. T. Peters:Trans. TMS-AIME, 1967, vol. 239, p. 1981.

H. Kessler and W. Pitsch:Acta Met., 1967, vol. 15, p. 401.

S. Shapiro and G. Krauss:Trans. TMS-AIME, 1967, vol. 239, p. 1408.

S. Jana and C. M. Wayman:Trans. TMS-AIME, 1967, vol. 239, p. 1187.

R. W. Rohde, J. R. Holland, and R. A. Graham:Trans. TMS-AIME, 1968, vol. 242, p. 2017.

W. Pitsch:Trans. TMS-AIME, 1968, vol. 242, p. 2019.

S. Shapiro and G. Krauss:Trans. TMS-AIME, 1968, vol. 242, p. 2021.

A. Goldberg:ASM Trans. Quart., 1969, vol. 62, p. 219.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Saul, G., Roberson, J.A. & Adair, A.M. The effects of thermal treatment on the austenitic grain size and mechanical properties of 18 Pct Ni maraging steels. Metall Trans 1, 383–387 (1970). https://doi.org/10.1007/BF02811546

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02811546