Abstract

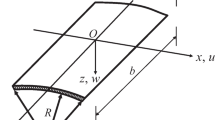

We describe a method for the evaluation of the dynamic stress intensity factors under the action of dynamic loading. The method is based on the solution of the problem of limiting equilibrium for a cylindrical specimen of finite dimensions containing a circumferential crack. In the process of solution, we use the experimental load-time diagram. We establish a simple formula for the evaluation of the dynamic stress intensity factors depending on the history of loading of the specimen. The obtained results serve as a basis of an experimental procedure of determination of the crack-growth resistance of materials. The results of specially performed experimental investigations confirm the efficiency of the proposed formulas.

Similar content being viewed by others

References

O.E. Andreikiv and I. V. Rokach. “A simplified method for the determination of the time dependence of the stress intensity factor in testing beam specimens for support-free impact bending.”Fiz.-Khim. Mekh. Mater..25. No. 5. 42–51 (1989).

I. V. Rokach. “A simplified method for the determination of the time dependence of the dynamic stress intensity factor in testing beam specimens for three-point impact bending,”Fiz.-Khim. Mekh. Mater..26. No. 3. 79–83 (1990).

O. C. Zienkiewich,The Finite Element Method in Engineering Science, McGraw-Hill. London (1971).

V. Z. Parton and V. G. Boriskovskii.Dynamic Fracture Mechanics [in Russian], Mashinostroenie. Moscow (1985).

G. E. Nash, “An analysis of the forces and bending moments generated during the notched beam impact test,”Eng. Fract. Mech..5. 269–285(1969).

V. G. Boriskovskii and V. Z. Parton, “Numerical analysis of the intensity factors in a square plate with central crack under vibration loading by the finite-element method.” in:Improvement of the Design of Machines and Equipment in Chemical Industry [in Russian], Izd. MIKhM. Moscow (1982). pp. 20–22.

I. V. Rokach, “Modal approach for processing one- and three-point bend test data for DSIF-time diagram determination. Pan 1. Theory, ”Fatigue Fract. Eng. Mat. Struct..21, 1007–1014(1998).

I. V. Rokach. “Modal approach for processing one- and three-point bend test data for DSIF-time diagram determination. Part 2. Calculations and results.”Fatigue Fract. Eng. Mat. Struct.,21. 1015–1026 (1998).

K. Kishimoto. S. Aoki. and M. Sakata. “Simple formula for dynamic stress intensity factors of precracked Charpy specimen.”Eng. Fract. Mech.,13, 501–508 (1980).

K. Kishimoto. K. Kuroda. S. Aoki. and M. Sakata. “Simple formulae for dynamic fracture mechanics parameters of elastic and viscoelastic three-point bend specimens based on Timoshenko’s beam theory.” in:Proc. of the Sixth Internat. Conf. on Fracture, Vol. 5. Pergamon. Oxford (1984). pp. 3177–3184.

K. Kishimoto. K. Fujino. S. Aoki. and M. Sakata. “A simple formula for the dynamic stress intensity factor of a freely-supported bend specimen.”JSME Int. J. Ser: I. 33. 51–56 ( 1990).

V. G. Biderman.Theory of Mechanical Vibrations [in Russian], Vysshaya Shkola. Moscow (1980).

G. A. Korn and T. M. Kom.Mathematical Handbook for Scientists and Engineers. Definitions, Theorems, and Formulas for Reference and Review. McGraw-Hill. New York (1968).

S. Timoshenko. D. H. Young, and W. Weaver, Jr.,Vibration Problems in Engineering. Wiley, New York (1974).

R. G. Grimes. J. G. Lewis, and H. D. Simon. “A shield block Lanczos algorithm for solving sparse symmetric generalized eigenproblems, ”SIAM J. Matrix Anal. AppL 15. No. 1. 228–272(1994).

V. V. Panasyuk. O. E. Andreikiv, and S. E. Kovchyk.Methods for the Evaluation of Crack Resistance of Structural Materials [in Russian], Naukova Dumka. Kiev (1977).

J. P. Benthem and W. T. Koiter, “Asymptotic approximations to crack problems,” in:Methods of Analysis and Solutions of Crack Problems, Nordhoff, Leyden (1973). pp. 131–178.

L. M. Keer. J. M. Freedman. and H. A. Watts, “Infinite tensile cylinder with circumferential edge crack.”Lett. Appl. Eng. Sei..5. 129–139(1977).

G. Wich,Ein Beitrag zur Ermittlung von RisszÄhigkeiten bei schlaganiger Belastung, PhD Thesis, München ( 1986).

O. E. Andreikiv. S. E. Kovchyk. I. V. Khodan. and V. M. Boiko. “On the methods for the evaluation of the dynamic crack-growth resistance of structural materials.”Probl. Mashinostr. Avtomat. No. 5–6. 22–35 (1997).

S. E. Kovchyk, I. V. Khodan. T. S. Zamora et al., “Information and measuring system for the dynamic investigation of structural materials.”Fiz.-Khim. Mekh. Mater.,30. No. 3, 133–136 (1994).

I. V. Khodan. S. E. Kovchyk. and V. M. Boiko. “Development and verification of new experimental procedures aimed at the prediction of the behavior of structural materials under dynamic loading.” in:Mechanics and Physics of Fracture of Building Materials and Structures [in Ukrainian], Kamenyar. L’viv (1998), pp. 561–567.

Author information

Authors and Affiliations

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 36, No. 3, pp. 59–66, May-June, 2000.

Rights and permissions

About this article

Cite this article

Andreikiv, O.E., Boiko, V.M., Kovchyk, S.E. et al. Dynamic tension of a cylindrical specimen with circumferential crack. Mater Sci 36, 382–391 (2000). https://doi.org/10.1007/BF02769599

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02769599