Abstract

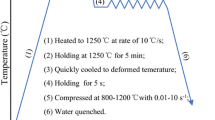

Metadynamic recrystallization has been investigated in three plain carbon steels (ENIA, EN2 and EN24) through the use of hot interrupted compression tests on a wedge plastometer. Holding time was 0.5 s between passes. Strain rates of 0.05 and 0.12/s and small strain increments of 3, 5 and 7% were employed. Test temperatures were varied between 800 and 1100°C.

Various incremental and continuous stress strain curves were highlighted at different temperatures and strain rates for 3 steels, ENIA, EN2 and EN24, resulting in varying flow stresses and strains. Highest peak stress was 180 MPa for EN24 at peak strain of 0.25 and 900°C, with a strain rate 0.12/s. Peak strain values for all steels at 1100°C was 0.133 at a strain rate of 0.05/s and 0.15 at a strain rate of 0.12/s.

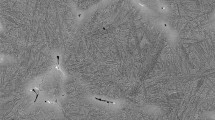

Strain accumulation resulted in dynamic and metadynamic recrystallization with refinement to about 15 μm for dynamic and 22 μm for metadynamic recrystallization. Fractional softening,X, decreased from 0.27 to 0.12 as recrystallization times in metadynamic recrystallization increased from 0.9 s to 1.5 s at 1100°C. Time for 50% metadynamic recrystallization was also reduced as temperature increased.

For ENIA, a drop from 10000 s to 20 s, as temperature increased from 800 to 1100°C was observed. For EN24 and EN2 steels, a drop from 4000 s to 6 s for similar temperature rise was observed.

Metadynamic recrystallization (at strains higher than critical strain) is observed to be a strong function of strain rate and a very weak function of temperature and strain. It significantly refined the austenite grain size prior to transformation.

Similar content being viewed by others

References

Djaic R A P and Jonas J J 1973Metall. Trans. 4 621

Hodgson P D 1997The metadynamic recrystallization of steels, THERMEC’97, International conference on thermomechanical processing of steels and other materials (eds) T Chandra and T Sakai (Wollongong: The Minerals, Metals & Materials Society) pp 121–131

Lenard J G, Pietrzyk M and Cser L 1999Mathematical and physical simulation of the properties of hot rolled products (Amsterdam: Elsevier Publications) pp 150–166

McQueen H J and Bergerson S 1979Metal Soc. J. 6 25

Morgridge A R 1990Study of yield behaviour of metals during incremental compression tests, under hot working conditions, using a wedge plastometer (Australia: Materials Forum)14 pp 20–26

Sellars C M 1979The physical metallurgy of hot working and forming processes (eds) C M Sellars and G J Davies (London: The Metals Society) pp 3–15

Tamura I, Ouchi C, Tanaka T and Sekine H 1988Thermomechanical processing of high strength low alloy steels (London: Butterworths Publications) pp 49–53

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Morgridge, A.R. Metadynamic recrystallization in C steels. Bull Mater Sci 25, 291–299 (2002). https://doi.org/10.1007/BF02704121

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02704121