Abstract

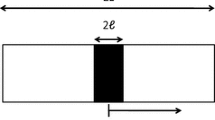

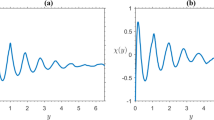

Gas mixing behavior was investigated in a residence time distribution experiment in a bubbling fluidized bed of 0.07 m ID and 0.80 m high. Linear low density polyethylene (LLDPE) particles having a mean diameter of 772 Μm and a particle size range of 200-1,500 Μm were employed as the bed material. The stimulus-response technique with CO2 as a tracer gas was performed for the RTD study. The effects of gas velocity, aspect ratio (H0/D) and scale-up on the axial gas dispersion were determined from the unsteady-state dispersion model, and the residence time distributions of gas in the fluidized bed were compared with the ideal reactors. It was found that axial dispersion depends on the gas velocity and aspect ratio of the bed. The dimensionless dispersion coefficient was correlated with Reynolds number and aspect ratio.

Similar content being viewed by others

References

Bang, J. H., Kim, Y. J., Namkung, W. and Kim, S. D., “Radial Gas Mixing Characteristics in a Downer Reactor,”Korean J. Chem. Eng.,16, 624 (1999).

Danckwerts, P. V., “Continuous Flow Systems; Distribution of Residence Times,”Chem. Eng. Sci.,2, 1 (1953).

Danckwerts, P. V., Jenkins, J.W. and Place, G., “The Distribution of Residence-Times in an Industrial Fluidized Reactor,”Chem. Eng. Sci.,3, 26 (1954).

Edwards, M. and Avidan, A., “Conversion Model Aids Scale-up of Mobil’s Fluid Bed MTG Process,”Chem. Eng. Sci.,41, 829 (1986).

Gilliland, E. R. and Mason, E. A., “Gas and Solid Mixing in Fluidized Beds,”Ind. Eng. Chem.,41, 1191 (1949).

Gilliland, E. R. and Mason, E. A., “Gas Mixing in Beds of Fluidized Solids,”Ind. Eng. Chem.,44, 218 (1952).

Goedecke, R., Schugerl, K. and Todt, J., “Influence of the Sorption Process on the Gas Residence Time Distribution in Bench Scale Fluidized Beds,”Powder Technol.,21, 227 (1978).

Guo, F., “Gas Flow and Mixing Behavior in Fine-powder Fluidized Bed,”AIChE J.,33, 1895 (1987).

Kato, K. and Wen, C. Y., “Bubble Assemblage Model for Fluidizedbed Catalytic Reactors,”Chem. Eng. Sci.,24, 1351 (1969).

Khang, D. Y. and Lee, H. H., “Particle Size Distribution in Fluidized Beds for Catalytic Reactors,”Chem. Eng. Sci.,52, 412 (1997).

Kunii, D. and Levenspiel, O., “Bubbling Bed Model for Kinetic Process in Fluidized Beds,”Ind. Eng. Chem. Process Des. Dev.,7, 481 (1968).

Latham, R. and Potter, O. E., “Back-mixing of Gas in a 6-in Diameter Fluidized Bed,”Chem. Eng. J.,1, 152 (1970).

Levenspiel, O. and Smith, W. K., “Notes on the Diffusion-type Model for the Longitudinal Mixing of Fluids in Flow,”Chem. Eng. Sci.,6, 227 (1957).

Li, J. and Weinstein, H., “An Experimental Comparison of Gas Backmixing in Fluidized Beds across the Regime Spectrum,”Chem. Eng. Sci.,44, 1697 (1989).

May, W. A., “Fluidized-Bed Reactor Studies,”Chem. Eng. Prog.,55(12), 49 (1959).

Namkung W. and Kim, S. D., “Gas Mixing Characteristics in a Fast Fluidized Bed,”HWAHAK KONGHAK,36, 797 (1998).

Nauman, E. B., “Residence Time Distributions and Micromixing,”Chem. Eng. Commun.,8, 53 (1981).

Stephens, G. K., Sinclair, R. L. and Potter, O. E., “Gas Exchange Between Bubbles and Dense Phase in a Fluidized Bed,”Powder Technol.,1, 157 (1967).

van Deemter, J. J., “Mixing and Contacting in Gas Solid Fluidizedbeds,”Chem. Eng. Sci.,13, 143 (1961).

Wen, C. Y. and Fan, L. T., “Models for Flow Systems and Chemical Reactors,” Marcel Dekker, New York (1975).

Yates, J. G. and Constans, J. A. P., “Residence Time Distributions in a Fluidized Bed in which Gas Adsorption Occurs: Stimulus-Response Experiments,”Chem. Eng. Sci.,28, 1341 (1973).

Yoshida, K., Kunii, D. and Levenspiel, O., “Axial Dispersion of Gas in Bubbling Fluidized Beds,”Ind. Eng. Chem. Fund.,8, 402 (1969).

Zacca, J. J., Debling, J. A. and Ray, W. H., “Reactor Residence Time Distribution Effect on the Multistage Polymerization of Olefins,”Chem. Eng. Sci.,52, 1941 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, H.I., Chung, CH., Han, G.Y. et al. Axial gas dispersion in a fluidized bed of polyethylene particles. Korean J. Chem. Eng. 17, 292–298 (2000). https://doi.org/10.1007/BF02699043

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02699043