Abstract

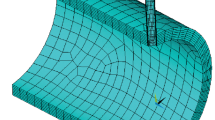

The stress-strain history of Basic Oxygen Furnace hood tubes during thermal cycling has been computed using heat flow and stress analyses. The steady-state temperature distribution in a transverse section of the tube was computed at a location where gas temperature in the hood could be expected to be a maximum. Calculations were performed for peak gas temperatures in the range 1950 to 2480 °C (3500 to 4500 °F). The stress-strain history of an element of material located at the center of the tube hot face was traced for three consecutive cycles using elasto-plastic finite-element analysis. It has been shown that the state of stress in the element alternates between compression and tension as the tube successively heats and cools. Yielding and plastic flow occurs at the end of each half of a given cycle. It was postulated that owing to repctitive yielding, plastic strain energy accumulates causing failure of the tubes by fatigue in the low cycle region. Using fatigue theory a conservative estimate for tube life was arrived at. In-plant observations support this mechanism of failure, and the number of cycles within which tube cracking was observed compares reasonably with model predictions. Utilizing the heat flow and stress models it was recommended that tube life could be enhanced by changing the tube material to ARMCO 17-4 pH or AISI 405 steel or alternatively reconstructing hoods with AISI 316L tubes of reduced thickness. These recommendations were based on the criterion that low-cycle fatigue failure could be averted if the magnitude of the cyclic strain could be reduced or if macroscopic plastic flow could be prevented.

Similar content being viewed by others

References

“Survey of the Maintenance and Repair Problems of Basic Oxygen Steel Making Off-Gas Systems”. International Iron and Steel Institute Committee on Technology, Belgium, 1981.

W. Edgar; Inland Steel Company. East Chicago. IN. private communication, 1982.

R. W. Adams: “Waste Gas Handling”, chap. 10.BOF Steelmaking, Process Technology Division of the Iron and Steel Institute of the AIME, Iron and Steel Society of AIME, New York, NY, 1973, vol. 3.

G. Forsythe and C. B. Moler:Computer Solution of Linear Algebraic-Systems, Prentice-Hall, Englewood, NJ, 1967.

H.C. Hottel: “Radiant Heat Transmission”, chap. 4,Heat Transmission, 3rd ed., W. H. McAdams, ed., McGraw-Hill Book Company, New York, NY, 1964.

Marks Standard Handbook for Mechanical Engineers, T. Baumeister, E. Avallone.and T. Baumeister III, eds., 8th ed., McGraw-Hill Book Company, New York, NY, 1978, pp. 4–66.

F. W. Hutchinson:Industrial Heat Transfer, New York Industrial Press, New York, NY, 1952.

Marks Standard Handbook for Mechanical Engineers, T. Baumeister, E. Avallone, and T. Baumeister III, eds., 8th ed.. McGraw-Hill Book Company, New York, NY, 1978, pp. 4–66.

S. Timoshenko and G.H. MacCullough:Elements of Strength of Materials, D. Van Nostrand Company, New York, NY, 1954. p. 325.

S. Utku, M. S. M. Rao, and G. J. Dvorak: “Elas 65 Computer Program for Elastic-Thermoplastic Solids and Structures”, Structural Mechanics Series, No. 15, 1973, Duke University, Durham, NC.

Alloy Digest, AISI Type 316, Filing Code SS-114, Stainless Steel, February 1961.

D. Pecknerand I. M. Bernstein:Handbook of Stainless Steels, 1st ed., McGraw-Hill Book Company, New York, NY, 1977, pp. 19–1 and 21-1.

Source Book on Industrial Allov and Engineering Data, Paul M. Unterweiser, ed., ASM, Metals Park, OH, 1978, p. 223.

T. V. Duggans and J. Byrne:Fatigue as a Design Criterion, Mac-Millan Press Ltd., London, 1977, chap. 3, p. 47.

R. W. Smith, M. H. Hirschberg, and S. S. Manson:Fatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range, NASA TN D-1574, 1963.

S.S. Manson:Behavior of Materials in Stress Strain Cycling, chap. 4, “Thermal Stress and Low Cycle Fatigue.” McGraw-Hill Book Company, New York, NY, 1966.

ASME Boiler and Pressure Vessel Code. Case 1592–8, Fig. T 1420–1A, IB, 1973. $

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Samarasekera, I.V. Mathematical modeling of thermal stresses in basic oxygen furnace hood tubes. Metall Trans B 16, 247–261 (1985). https://doi.org/10.1007/BF02679716

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02679716