Abstract

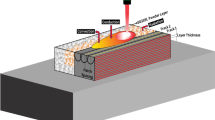

Spray deposition is a novel manufacturing process which is currently being developed for producing near-net-shape preforms. Spray deposition involves the creation of a spray of droplets by a gas atomizer and the consolidation of these droplets on a substrate to create a preform. In order to maximize the metallurgical benefits of spray deposition, a thorough characterization of momentum and heat transfer in the gas-atomized spray is required. The present paper describes measurements of particle size, gas velocity, particle velocity, and spray temperature in gasatomized Sn-Pb sprays. Measurements were performed on steady-state axisymmetric sprays which were generated using a close-coupled gas atomizer with Sn-5 wt p t Pb and Sn-38 wt p t Pb alloys, atomizer gas flow rates of 2.5 g/s (0.56 MPa) and 3.4 g/s (1.04 MPa), melt flow rates of 35 and 61 g/s, and atomizer-substrate distances of 180 and 360 mm. Gas velocities in the range to 4 m/s were measured using Pitot tube and laser Doppler anemometry (LDA). Droplet velocities in the range 3 to 32 m/s were determined from photographic streak-length measurements and LDA. Oil calorimetry of the spray enthalpy indicated that the spray temperature decreased with increasing axial distance from the gas atomizer, increasing gas flow rate, and decreasing melt flow rate.

Similar content being viewed by others

References

R.G. Brooks, C. Moore, A.G. Leatham, and J.S. Coombs:Metall. Met. Form., 1977, vol. 44, pp. 157–63.

B.A. Rickinson, F.A. Kirk, and D.R.G. Davies:Powder Metall., 1981, vol. 24 (1), pp. 1–6.

R.H. Bricknell:Metall. Trans. A, 1986, vol. 17A, pp. 583–91.

H.C. Fiedler, T.F. Sawyer, and R.W. Koop: CRD Report No. 85CRD073, General Electric Co., Schenectady, NY, 1985.

H.C. Fiedler, T.F. Sawyer, and R.W. Koop: CRD Report No. 86CRD113, General Electric Co., Schenectady, NY, 1986.

A.R.E. Singer:Metall. Mater., 1970, vol. 4, pp. 246–57.

P.J. Read, K.J. Latimer, T.D.W. Reynolds, and D. Munson: British Patent No. 1431895, 1976.

E.J. Lavernia, G. Rai, and N.J. Grant:Int. J. Powder Metall., 1986, vol. 22 (1), pp. 9–16.

R.E. Lewis, J.M. Fitzpatrick, D.D. Crooks, A.R.E. Singer, and W.N. Jenkins: SAE Technical Paper Series No. 841514, Aerospace Congress and Exposition, Long Beach, CA, Oct. 1984.

C.A. Wilson, D.W. Gasson, and R. Avery: British Patent No. 1531222, 1978.

A.R.E. Singer and S. Ozbek:Powder Metall., 1985, vol. 28 (2), pp. 72–78.

E.A. Feest: U.K. Patent Application No. 2172826, 1986.

A.G. Gillen and B. Cantor:Ada Metall., 1985, vol. 33 (10), pp. 1813–21.

B.P. Bewlay and B. Cantor:Int. J. Rapid Solidification, 1987, vol. 3, pp. 30–37.

J. Mishin, M. Vardelle, J. Lesinski, and P. Fauchais:J. Phys. E, 1986, vol. 20, pp. 620–25.

P. Mathur and D. Apelian: Drexel University, Philadelphia, PA, unpublished research, 1987.

P. Mathur, D. Apelian, and A. Lawley:Acta Metall., 1989, vol. 37 (2), pp. 429–43.

A.R.E. Singer, J.S. Coombs, and A.G. Leatham: inModern Developments in Powder Metallurgy, H.H. Hausner and W.E. Smith, eds., Plenum Press, New York, NY, 1974, vol. 8, pp. 263–74.

M.H. Kim and H. Jones: inRapidly Quenched Metals, T. Masumoto and H. Suzuki, eds., The Japan Institute of Metals, Sendai, 1982, pp. 85–93.

N.P. Smith, J.O.W. Noms, D.J. Hemsley, and M.L. Yeoman: inProc., Int. Conf. on Liquid Atomization and Spraying Systems, London, 1985.

B.P. Bewlay: D. Phil. Thesis, University of Oxford, Oxford, United Kingdom, 1987.

B.P. Bewlay and B. Cantor:Mater. Sci. Eng., 1989, vol. 118, pp. 207–22.

Y.S. Touloukian:Thermophysical Properties of Matter, Plenum Press, New York, NY, 1970, vol. 4.

K.P. Rao and S.P. Mehotra: inModern Developments in Powder Metallurgy, H. Hausner, ed., Plenum Press, New York, NY, 1980, vol. 2, pp. 113–22.

S.P. Mehotra and P.Y. Kedhar:Trans. Indian Inst. Met., 1980, vol. 33, pp. 361–69.

H. Lubanska:J. Met., 1970, vol. 22, pp. 45–49.

J.S. Thompson:J. Inst. Met., 1948, vol. 74, pp. 101–32.

U.R. Date, G.S. Tendolkar, and M.N. Vartak:Int. J. Powder Metall., 1967, vol. 3 (2), pp. 49–62.

S.L. Shinde and G.S. Tendolkar:Powder Metall. Int., 1977, vol. 9 (4), pp. 180–85.

Smithells Metals Reference Book, 6th ed., E.A. Brandes, ed., Butterworth’s, London, 1983, Sec. 14.

Author information

Authors and Affiliations

Additional information

Formerly Doctoral Student, Department of Metallurgy and Science of Materials, Oxford University

Rights and permissions

About this article

Cite this article

Bewlay, B.P., Cantor, B. Modeling of spray deposition: Measurements of particle size, gas velocity, particle velocity, and spray temperature in Gas-Atomized sprays. Metall Trans B 21, 899–912 (1990). https://doi.org/10.1007/BF02657816

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02657816