Abstract

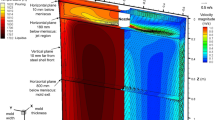

In the first part of this paper, the working principle of a new electromagnetic continuous casting process is described. The main peculiarities of this process are (1) the presence in the sump of a strong electromagnetically driven forced convection, which promotes the production of a fine equiaxed structure, and (2) the fact that the thickness of the segregation zone tends toward zero. Local measurement methods are applied to the study of electromagnetic and hydrodynamic phe-nomena inside the sump of aluminum alloy billets. Further, the evolution of both the grain size and the thickness of the segregated surface layer with the electric power input is presented. In summary, this new technology presents the advantages of avoiding the addition of grain refiners and substantially reducing the scalping operation.

Similar content being viewed by others

References

B. Chalmers:Principle of Solidification, R. Krieger Publishing Company, Malabar, Florida, 1982, pp. 253–97.

M. Flemings:Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 252–58.

G. Abbaschian and S. David:Grain Refinement in Castings and Welds, TMS-AIME, 1983, pp. 3-65.

L. Labarre, R. James, J. Witters, R. O'Malley, and M. Emptage:J. de Physique, supp. 9, 1987, pp. 93–102.

M. Birch and A. Cowell:J. de Physique, 1987, supp. 9, pp. 103-08.

Ch. Vivès, B. Forest, and J.P. Riquet: U.S. Patent No. 511388, issued June 1986.

H. Marr:Iron Steel Int., 1979, no. 2, pp. 29-41.

A. Tsavaras and H. Brody:J. Metals, 1984, vol. 36 (1), pp. 31–37.

Ch. Vivès and Ch. Perry:Int. J. Heat Mass Transfer, 1986, vol. 29 (1), pp. 21–33.

R. Ricou and Ch. Vivès:Int. J. Heat Mass Transfer, 1982, vol. 25 (10), pp. 1579–88.

Ch. Vives and R. Ricou:Metall. Trans. B, 1985, vol. 16B, pp. 377–84.

Erach D. Tarapore and James W. Evans:Metall. Trans. B, 1976, vol. 7B, pp. 343–51.

Erach D. Tarapore, James W. Evans, and J. Langfeldt:Metall. Trans. B, 1977, vol. 8B, pp. 179–84.

J. Szekely and C. Chang:Ironmaking and Steelmaking, 1977, no. 3, part 1, pp. 190-95.

J. Szekely and C. Chang:Ironmaking and Steelmaking, 1977, no. 3, part 2, pp. 196-204.

K. Buxmann:Heat and Mass Transfer in Metallurgical Systems, Hemisphere Publishing Corporation, Washington, DC, 1981, pp. 341–47.

D.K. Stemple, E.N. Zulueta, and M.C. Flemings:Metall. Trans. B, 1982, vol. 13B, pp. 503–09.

Ch. Vivès and B. Forest:Light Metals, 1987, pp. 769-78.

R. Riquet and J.L. Meyer:Light Metals, 1987, pp. 779-84.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vives, C. Electromagnetic refining of aluminum alloys by the CREM process: Part I. Working principle and metallurgical results. Metall Trans B 20, 623–629 (1989). https://doi.org/10.1007/BF02655919

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02655919