Abstract

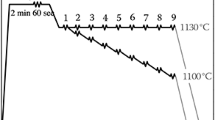

A laboratory simulation of hot-rolling schedules, which employs a sequence of high-speed compressions performed over a range of temperatures, was used to determine the effects of composition and processing variables on the state of the austenite at several points in the hot-rolling procedure. The type and quantity of carbide and/or nitride forming elements (Nb(Cb), V, Al) in the steels were varied to produce precipitates at various points in the hot-working range of temperatures. Time-temperature-deformation schedules were designed around schedules currently used in the hot-re-duction of plate steels; variations were introduced to determine the effects of processing variables on the development of the austenite structures. At various points in the deformation schedule, specimens were quenched out and changes in the austenite grain structure were examined. Changes in the volume and aspect ratio of the prior-austenite grains were used as measures of the degree of austenite recrystallization. At temperatures above the precipitation-start temperature, light reductions (< 10 pct) caused grain coarsening. Coarsening could be eliminated by increasing the reduction per pass, decreasing the rolling temperatures, or increasing the concentration of carbide or nitrideforming elements to raise the precipitation-start temperature. It is clear from these results that attempts to study structural changes that occur during plate rolling by using a few high-reduction passes may produce erroneous results.

Similar content being viewed by others

References

H. Chino and K. Wada:Yawata Technical Report, no. 251, pp. 75–100, 1965.

L. Meyer, H. Biehler, and F. Heisterkamp:Thyssen Forschung, 1971, vol. 3, pp. 8–43.

G. R. Speich, R. L. Miller, U.S. Steel Corporation: Unpublished research, Research Laboratory, Monroeville, 1976.

The Hot Deformation of Austenite, J. B. Balance, ed., TMS-AIME, New York, 1977.

Microalloying 75, Union Carbide Corporation, New York, 1977.

Processing and Properties of Low-Carbon Steel, J. M. Gray, ed., TMS-AIME, New York, 1973.

A. le Bon, J. Rofes-Vernis, and C. Rossard:Metal Sci., 1975, vol. 9, pp. 36–40.

J. N. Cordea and R. E. Hook:Met. Trans., 1970, vol. 1, pp. 111–18.

R. A. Grange:Trans. ASM, 1966, vol. 59, pp. 26–48.

Author information

Authors and Affiliations

Additional information

Formerly a summer student with U. S. Steel Research Laboratory.

This paper is based on a presentation made at a symposium on “Precipitation Processes in Structural Steels” held at the annual meeting of the AIME, Denver, Colorado, February 27 to 28, 1978, under the sponsorship of the Ferrous Metallurgy Committee of The Metallurgical Society of AIME.

Rights and permissions

About this article

Cite this article

Cuddy, L.J., Bauwin, J.J. & Raley, J.C. Recrystallization of austenite. Metall Trans A 11, 381–386 (1980). https://doi.org/10.1007/BF02654562

Issue Date:

DOI: https://doi.org/10.1007/BF02654562