Abstract

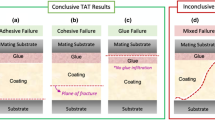

ASTM Standard C633-79, “Standard Test Method for Adhesion or Cohesive Strength of Flame-Sprayed Coatings,” is widely used in industry and research for evaluating bond strengths of thermal spray coatings. Tests are conducted by applying the coating to the end of a cylindrical test specimen 25.4 mm (1 in.) in diameter by 25.4 mm (1 in.) long. The coating surface is bonded to an uncoated cylinder of the same material and geometry. The force required to pull the cylinders apart is recorded. The bond strength is calculated by dividing the maximum force by the area of the 1 -in. diameter cylinder assuming that the stress is uniform over the area where the debonding occurs.

A combination of finite-element stress analysis and experimental stress analysis using strain gages was used to evaluate the stresses at the interface between the coating and substrate. Finite-element analysis of the standard specimen geometry shows that the maximum stress at the coating interface can be 25 % higher than the average stress. An elongated specimen was selected, constructed, and evaluated to produce the uniform stress distribution assumed by ASTM C633-79. Strain gage measurements and epoxy tensile tests have verified that the bond strengths measured with the elongated specimen provide better estimates of bond strengths than tests with the standard specimen.

Similar content being viewed by others

References

ASTM C633-79, "Standard Test Method for Adhesion or Cohesive Strength of Flame-Sprayed Coatings,“Annual Book of ASTM Standard, American Society for Testing and Materials, 1982

C.C. Berndt, Tensile Adhesion Testing Methodology for Thermally Sprayed Coatings,J Mater. Eng., Vol. 12(No. 2), 1990, p 151–158

Y. Shimizu, M. Sato, K. Maeda, and M. Kabayashi, Effect of Test Specimen Size upon Adhesive Strength of Flame Sprayed Coatings,Thermal Spray Coatings: Properties, Processes and Applications, F. Bernecki, Ed., ASM International, 1991. p 257-262

H.S. Ingham, Jr., Adhesion of Flame Sprayed Coatings,Adhesion Measurements of Thin Films, Thick Films, and Bulk Coatings,ASTM STP 640, K.L. Mittal, Ed., American Society for Testing and Materials, 1978, p 285-292

T.N. Rhys-Jones, “Applications of Thermally Sprayed Coating Systems in Aero Engines,”12th Int. Conf. Thermal Spraying, The Welding Institute, London, 1989, p 87–99

R.H. Unger and W.D. Grossklaus, “A Comparison of the Technical Properties of Arc Sprayed Versus Plasma Sprayed Nickel-5 Alumi-num,“ SAE Technical Paper Series, 28th Annual Aerospace/Airline Plating & Metal Finishing Forum & Exposition, San Diego, 1992

R.W. Smith, E. Harzenski, and T. Robisch,“The Structure and Properties of Thermally Sprayed TiC Particulate Reinforced Steel and Nickel-Chromium Alloy Powders,”12th Int. Conf, Thermal Spraying, The Welding Institute, Abinton Publishing, London, 1989, p 163–172

D.J. Greving and J.R. Shadley, Experimental Evaluations of Thermal Spray Coatings for Oil Field Equipment Applications,Thermal Spray: International Advances in Coating Technology, C.C. Berndt, Ed., ASM International, 1992, p 605-610

K.M. Howell, Evaluating Bond Strength of Metal Coatings over Concrete Surfaces,Mater. Perform., Vol 31 (No. 7), 1992, p 29–32

W. Han, E.F. Rybicki, and J.R. Shadley, Bond Strength Testing of Thermal Spray Coatings Using ASTM C633-79—Effect of Specimen Size on Test Results,Thermal Spray: International Advances in Coating Technology, C.C. Bemdt, Ed., ASM International, 1992, p 911-914

C.C. Berndt, Instrumented Tensile Adhesion Tests on Plasma Sprayed Thermal Barrier Coatings,J. Mater. Eng., Vol 11 (No. 4), 1989, p 275–282

P. Ostojic and C.C. Berndt, The Variability in Strength of Thermal Sprayed Coatings,Surf. Coat. Technol, Vol 34, 1988, p 43–50

S.D. Brown, B.A. Chapman, and G.P. Wirtz, Fracture Kinetics and Mechanical Measurement of Adherence,Thermal Spray Technology, D.L. Houck, Ed., ASM International, 1989, p 147–157

O. Ambroz and J. Krejcova, Determination of the Adhesive and Cohesive Fracture Modes of the Adhesion Tensile Test,Thermal Spray: International Advances in Coating Technology, C.C. Berndt, Ed., ASM International, 1992, p 921–927

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Han, W., Rybicki, E.F. & Shadley, J.R. An improved specimen geometry for ASTM C633-79 to estimate bond strengths of thermal spray coatings. JTST 2, 145–150 (1993). https://doi.org/10.1007/BF02652022

Issue Date:

DOI: https://doi.org/10.1007/BF02652022