Abstract

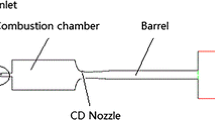

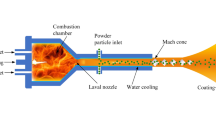

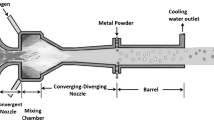

A transient two-dimensional numerical simulation of Inconel spraying in a high-velocity oxygen-fuel (HVOF) torch barrel was performed. The gas flow is treated as a continuum multicomponent chemically reacting flow, whereas particles are modeled using a stochastic particle spray model, fully coupled to the gas flow. The calculated results agree well with experimental data and show important statistical aspects of particle flow in the torch.

Similar content being viewed by others

Abbreviations

- A p :

-

Particle surface ares (m2 )

- A‖:

-

Projected surface area (m2 )

- C d :

-

Drag coefficient

- c :

-

Total molar concentration (mole m-3)

- C vs :

-

Solid specific heat (J/kg/K)

- C Vl :

-

Liquid specific heat (J/kg/K)

- D p :

-

Particle diameter (m)

- E p :

-

Particle internal energy (J)

- e :

-

Total thermal internal energy per unit mass (J/kg)

- e m :

-

Specific energy of solid atT m (J/kg)

- e p :

-

Specific energy of particle (J/kg)

- Fp :

-

Drag force (kg ⋅ m/s2)

- Δ fHo i :

-

Heat of formation of speciesi at absolute zero (J/kg)

- h :

-

Heat transfer coefficient (J/m2 /K/s)

- h i :

-

Specific enthalpy of speciesi (J/kg)

- I :

-

Unit dyadic

- i :

-

Unit vector inx direction

- j :

-

Unit vector iny direction

- K :

-

Thermal conductivity (J/m/K/s)

- k :

-

Turbulent kinetic energy per unit mass (m2/s2)

- L :

-

Latent heat of fusion (J/kg)

- M i :

-

Molecular weight

- M :

-

Mass flow rate (kg/s)

- m p]:

-

Particle mass (kg)

- P :

-

Momentum (kgm/s)

- P‖:

-

Component of P parallel to wall (kg.m/s)

- Prt :

-

Turbulent Prandtl number

- p :

-

Pressure (N/m2)

- q :

-

Heat flux (J/m2/s)

- Re :

-

Reynolds number

- Sct :

-

Turbulent Schmidt number

- T :

-

Temperature (K)

- T m :

-

Melting temperature (K)

- T p :

-

Particle temperature (K)

- t :

-

Time (s)

- t :

-

Unit vector parallel to wall

- U :

-

Component of u parallel to wall (m/s)

- u :

-

x component of u (m/s)

- u :

-

Fluid velocity (m/s)

- U p :

-

Particle velocity (m/s)

- V :

-

Inflow velocity (m/s)

- V cell :

-

Volume of computational cell (m )

- v :

-

y component of u (m/s)

- x :

-

Radial coordinate (m)

- x i :

-

Mole fraction of speciesi

- x p :

-

Particle position (m)

- y :

-

Axial coordinate (m)

- α:

-

Fluid volume fraction

- ε:

-

Dissipation rate of turbulent kinetic energy (m2/s3)

- εp :

-

Surface emissivity of particle

- η:

-

Efficiency

- λ :

-

Second viscosity coefficient (kg/m/s)

- μ:

-

Viscosity (kg/m/s)

- v:

-

Kinematic viscosity (m2/s)

- p:

-

Total mass density (kg/m3 )

- pi:

-

Partial mass density of speciesi (kg/m3)

- σ:

-

Stefan-Boltzmann constant (J/m2 /K4/s)

- τ :

-

Shear stress (kg/m/s2)

- ϕ:

-

Viscous dissipation (kg/m/s3)

- χ:

-

Particle degree of melting

- D:

-

Derriere (back) cell face

- F:

-

Front cell face

- f:

-

Gas around particle

- L:

-

Left cell face

- p:

-

Particle

- R:

-

Right cell face

- t:

-

Turbulence

- w:

-

Wall

- T:

-

Transpose

References

M.L. Thorpe and H. J. Richter, APragmatic Analysis and Comparison of the HVOF process,Thermal Spray: International Advances in Coat- ings Technology, C.C. Berndt, Ed., ASM International, 1992, p 137–147

G.D. Power, T.J. Barber, and L.M. Chiappetta, Analysis of a High Ve- locity Oxygen-Fuel (HVOF) Thermal Torch,AIAA/SAE/ASME/ASEE 28th Joint Propulsion Conference and Exhibit (Nashville, TN), AIAA paper 92-3598,1992

E.B. Smith, G.D. Power, T.J. Barber, and L.M. Chiappetta, Application of Computational Fluid Dynamics to the HVOF Thermal Spray Gun,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 805–810

W.D. Swank, J.R. Fincke, DC. Haggard, G. Irons, and R. Bullock, HVOF Particle Flow Field Characteristics,Thermal Spray Industrial Applications, C.C. Bemdt and S. Sampath, Ed., ASM International, 1994, p 319–324

A.A. Amsden, J.D. Ramshaw, P.J. O’Rourke, and J.K. Dukowicz, “KIVA: A Computer Program for Two- and Three-Dimensional Fluid Flows with Chemical Reactions and Fuel Sprays,” Report LA-10245- MS, Los Alamos National Laboratory, Feb 1985

A.A. Amsden, P.J. O’Rourke, and T.D. Butler, “KIVA-II: A Computer Program for Chemically Reactive Flows and Fuel Sprays,” Report LA-11560-MS, Los Alamos National Laboratory, May 1989

J.D. Ramshaw and C.H. Chang, Computational Fluid Dynamics Mod- elng of Multicomponent Thermal Plasmas,Plasma Chem. Plasma Process., Vol 12, 1992, p 299–325

C.H. Chang, Numerical Simulation of Alumina Spraying in an Argon- Helium Plasma Jet,Thermal Spray: International Advances in Coat- ings Technology, C.C. Berndt, Ed., ASM International, 1992, p 793–798

C.H. Chang and J.D. Ramshaw, Numerical Simulations of Argon Plasma Jets Flowing into Cold Air,Plasma Chem. Plasma Process., Vol 13,1993, p 189–209

J.R. Fincke, C.H. Chang, W.D. Swank, and D.C. Haggard,Entrainment and Demixing in Subsonic Thermal Plasma Jets: Comparison of Mea- surements and Predictions,Int. J. Heat Mass Transfer, Vol 37,1994, p 1673–1682

C.H. Chang and J.D. Ramshaw, Numerical Simulation of Nonequili- brium Effects in an Argon Plasma Jet,Phys. Plasmas, Vol 1, 1994, p 3698–3708

R.A. Gentry, R.E. Martin, and B.J. Daly, An Eulerian Differencing Method for Unsteady Compressible Flow Problems,J. Comput. Phys., Vol 1, 1966,p87–118

J.D. Ramshaw and J.K. Dukowicz, “APACHE: A Generalized-Mesh Eulerian Computer Code for Multicomponent Chemically Reactive Fluid Flow,” Report LA-7427, Los Alamos Scientific Laboratory, Jan 1979

C.H. Chang and J.D. Ramshaw, Numerical Simulation of High-Speed Plasma Flow Past an Enthalpy Probe,Plasma Chem. Plasma Proc- ess., in press

J.D. Ramshaw, Self-Consistent Effective Binary Diffusion in Multi- component Gas Mixtures,J. Non-Equilib. Thermodyn., Vol 15,1990, p 295–300

S. Gordon and B.J. McBride, “Computer Program for Calculation of Complex Chemical Equilibrium Compositions, Rocket Performance, Incident and Reflected Shocks, and Chapmann-Jouguet Detonations,” NASA SP-273, Vol 1, National Aeronautics and Space Administration, 1976, p1

J.D. Ramshaw and C.H. Chang, “Iteration Scheme for Implicit Calcula- tions of Kinetic and Equilibrium Chemical Reactions in Fluid Dynam- ics,”J. Comput. Phys.,Vol 116, 1995,p359–364

E. Gutheil, G. Balakrishnan, and F.A. Williams, Structure and Extinc- tion of Hydrogen-Air Diffusion Flames,Reduced Kinetics Mecha- nisms for Applications in Combustion Systems, N. Peters and B. Rogg, Ed., Springer-Verlag, 1993

M. Slack and A. Grillo, High Temperature Rate Coefficient Measure- ments of CO + OChemituminescence,Combust. Flame, Vol 59,1985, p189–196

W.D. Swank, J.R. Fincke, D.C. Haggard, and G. Irons, HVOF Gas Flow Characteristics,Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 313–318

E.J. Hopkins and M. Inouye, An Evaluation of Theories for Predicting Turbulent Skin Friction and Heat Transfer on Flat Plates at Supersonic and Hypersonic Mach Numbers,AIAA J., Vol 9,1971, p 993–1003

H. Schlichting,Boundary Layer Theory, McGraw-Hill, 1979

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chang, C.H., Moore, R.L. Numerical simulation of gas and particle flow in a high-velocity oxygen-fuel (HVOF) torch. JTST 4, 358–366 (1995). https://doi.org/10.1007/BF02648636

Issue Date:

DOI: https://doi.org/10.1007/BF02648636