Abstract

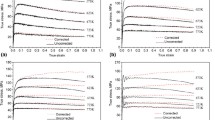

Isothermal flow curves were determined for aluminum alloy 2024-0 at temperatures of 145 to 482 °C and at constant true-strain rates of 10-3 to 12.5 s-1 using compression tests of cylindrical specimens. The average pressure was corrected for friction and for deformation heating to determine the flow stress. At 250 °C and above, the isothermal flow curves usually exhibited a peak followed by flow softening. At 145 °C the flow curves exhibited strain hardening. For 250 °C≦ T<= 482 °C, 10-3 s-1 ≦\(\dot \varepsilon \) ≦ 12.5 s-1, and ε ≦ 0.6 the flow behavior was represented by the constitutive equation σ =K (T, ε)\(\dot \varepsilon ^{m\left( {T,\varepsilon } \right)} \) where logK andm are simple functions of temperature and strain. The as-deformed microstructures generally supported the idea that flow softening in Al 2024-0 is caused by dynamic recovery. At the higher temperatures and strain rates, however, fine recrystallized grains were observed in local areas near second phase particles and at as-annealed grain boundaries. At 482 °C, there was evidence of re-dissolution of the CuMgAl2 precipitate.

Similar content being viewed by others

References

G. D. Lahoti, S. L. Semiatin, S. I. Oh, T. Altan, and H. L. Gegel:Advanced Processing Methods for Titanium, D. F. Hasson and C. H. Hamilton, eds., TMS-AIME, 1982, pp. 23-39.

S. L. Semiatin, S. I. Oh, and T. Altan: Technical Report AFWAL-TR- 83-4109, AFWAL Materials Laboratory, WP-AFB, OH 45433, 1985.

R. Raj:Metall. Trans. A, 1981, vol. 12A, pp. 1089–97.

Y. V. R. K. Prasad, H. L. Gegel, S. M. Doraivelu, J. C. Malas, J. T. Morgan, K. A. Lark, and D. R. Barker:Metall. Trans. A, 1984, vol. 15A, pp. 1883–92.

Y. V. R. K. Prasad: private communication, AFWAL Materials Laboratory, WP-AFB, OH 45433, 1984.

P. Dadras and W. R. Wells: Trans. ASME,Journal of Engineering for Industry, 1984, vol. 106, pp. 187–95.

S. L. Semiatin and G. D. Lahoti:Metall. Trans. A, 1981, vol. 12A, pp. 1705–17.

A. T. Male and M. G. Cockcroft:J. Inst. Metals, 1964, vol. 93, pp. 38–46.

V. DePierre and A. T. Male: Technical Report AFML-TR-69-28, AFWAL Materials Laboratory, WP-AFB, OH 45433, 1969.

P. Dadras and J. F. Thomas, Jr. :Compression Testing of Homogeneous Materials and Composites, R. Chait and R. Papirno, eds., ASTM, 1983, pp. 24-39.

P. Dadras and J. F. Thomas, Jr.:Metall. Trans. A, 1981, vol. 12A, pp. 1867–76.

A. Goldsmith, T. E. Waterman, and H. J. Hirschhorn:Handbook of Thermophysical Properties of Solid Materials, MacMillan, New York, NY, 1961, vol. 2, p. 755.

W. J. McGregor Tegart:Elements of Mechanical Metallurgy, MacMillan, New York, NY, 1966, p. 43.

Y. Adda and J. Philibert:La Diffusion dans les Solides, Presses Universitaires de France, Paris, 1966, vol. II, pp. 1129 and 1149.

J. Friedel:Dislocations, Addison-Wesley, Reading, MA, 1964.

B. Escaig:Dislocation Dynamics, A. R. Rosenfield, G. T. Hahn, A. L. Bernent, and R. I. Jaffee, eds., McGraw-Hill, New York, NY, 1968, pp. 653–77.

Author information

Authors and Affiliations

Additional information

Formerly Visiting Associate Professor, Wright State University, Dayton, OH 45435

Formerly a Mechanical Systems Engineering Student at Wright State University

Formerly a Materials Engineering Student at Wright State University

Formerly Director, Metallurgy Program, National Science Foundation, Washington, DC

Rights and permissions

About this article

Cite this article

Charpentier, P.L., Stone, B.C., Ernst, S.C. et al. Characterization and modeling of the high temperature flow behavior of aluminum alloy 2024. Metall Trans A 17, 2227–2237 (1986). https://doi.org/10.1007/BF02645920

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02645920