Abstract

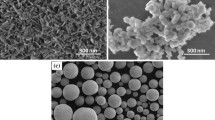

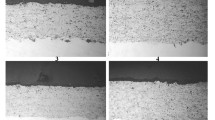

High hardness alumina coatings were formed at atmospheric pressure by gas tunnel plasma spraying, and the characteristics of these coatings were investigated. The hardness on the cross section of the alumina coating at a short spraying distance was more than 1300 HV, and the thickness of the hard layer increased with an increase of power input. The microstructure of the alumina coating was investigated by microscopy and x-ray diffraction (XRD) methods. It was ascertained that the cell size was small (∼10 μn), and α-alumina was dominant in the high hardness layer of the coating. Finally, the effect of plasma energy was estimated from these results.

Similar content being viewed by others

References

Thermal Spraying Handbook, Jpn. Inst. Thermal Spraying, Shin-gi- jutsu Kaihatsu Center, 1987 (in Japanese)

Y. Arata, A. Kobayashi, and Y. Habara, Ceramic Coatings Produced by Means of a Gas Tunnel Type Plasma Jet,J. Appl. Phys., Vol 62 (No. 12), 1987, p 4884–4889

Y. Arata, A. Kobayashi, and Y. Habara, Formation of Alumina Coating by Gas Tunnel Type Plasma Spraying Apparatus,J. High Temp. Soc., Vol 13 (No. 3), 1987, p 116–124 (in Japanese)

A. Kobayashi, S. Kurihara, Y. Habara, and Y. Arata, Deposit Charac- teristic of Sprayed Powder and Ceramic Coating Characteristic Formed by Gas Tunnel Type Plasma Spraying,Q. J. Jpn. Weld. Soc., Vol 8 (No. 4), 1990, p 457–463 (in Japanese)

Y. Arata, A. Kobayashi, and S. Kurihara, Effect of Spraying Conditions in Gas Tunnel Type Plasma Spraying,J. High Temp. Soc., Vol 15 (No. 5), 1989, p 210–216 (in Japanese)

J. Hasui,J. Weld. Soc. Jpn., Vol 37 (No. 4), 1987, p 52–58

A. Kobayashi, New Applied Technology of Plasma Heat Source,Weld. Int., Vol 4 (No. 4), 1990, p 276–282

A. Kobayashi, Y. Habara, and Y. Arata, Structure of Alumina Coating Produced by Gas Tunnel Type Plasma Spraying,J. High Temp. Soc., Vol 18 (No. 2), 1992, p 89–96 (in Japanese)

Crystal Optics, Jpn. Soc. Appl. Phys. Morikita Shuppan, 1975 (in Japanese)

N. Iwamoto, N. Umesaki, et al., Bond Adhesion of Plasma-Sprayed Alumina Coatings and The Effect of Pretreatments of Metals on Adhe- sive Strength,J. High Temp. Soc., Vol 12 (No. 3), 1986, p 130–136 (in Japanese)

Y. Horie, Development of Functionality Materials by Plasma Spraying,Kinzoku, No. 8, 1988, p 71-75 (in Japanese)

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kobayashi, A. Characteristics of high hardness alumina coatings formed by gas tunnel plasma spraying. JTST 5, 298–302 (1996). https://doi.org/10.1007/BF02645881

Issue Date:

DOI: https://doi.org/10.1007/BF02645881