Abstract

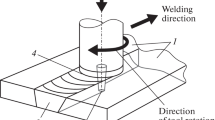

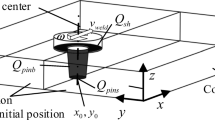

Based on the finite difference method and the enthalpy model of Shamsundar, a computer model was developed to describe the steady state, two-dimensional heat flow during the welding of thin plates. In order to allow accurate computations of the weld pool configuration, the size of the mushy zone and the temperature distribution near the heat source, a grid mesh of variable spacings was used. The heat of fusion, the size and distribution of the heat source, the temperature dependence of thermal properties, the heat conduction in the welding direction and the surface heat loss during welding were considered. The model was first checked with Rosenthal’s analytical solution of welding heat flow using pure aluminum for examples. Experimental results of 6061 aluminum, including the width of the fusion zone and the thermal cycles at positions in both the fusion and the heat affected zones, were then compared with the calculated results of the heat flow model. The agreement was very good. Finally, in order to demonstrate systematically the quantitative effect of welding parameters such as the heat input, the welding speed and the preheating of the workpiece, a series of computations were made based upon 6061 aluminum.

Similar content being viewed by others

References

W. F. Savage and A. H. Aronson:Weld. J., 1966, vol. 45, pp. 85s-89s.

W. F. Savage, E. F. Nippes, and J. S. Erickson:Weld. J., 1976, vol. 55, pp. 213s-21s.

S. A. David and C. T. Liu:Met. Technol., 1980, vol. 7, pp. 102–06.

J. E. Gould and J. C. Williams: Private Communication, Carnegie-Mellon University, Pittsburgh, PA, 1981.

T. Ganaha, B. P. Pearce, and H. W. KernMetall. Trans. A, 1980, vol. 11 A, pp. 1351–59.

D. Rosenthal:Weld. J., 1941, vol. 20, pp. 220s-34s.

W. F. Hess, L. L. Merrill, E. F. N ppes, Jr., and A. P. Bunk:Weld. J., 1943, vol. 22, pp.377s-422s.

N. N. Rykalin:Calculation of Heat Processes during Welding, VEB-Verlag Technik, Berlin, 1957.

P. S. Myers, O. A. Uyehara, and G. L. Borman:Weld. Res. Counc. Bull., July, 1967, no. 123.

R. J. Grosh, E. A. Trabant, and G. A. Hawkins:Q. Appl. Math., 1955, vol. 13, pp. 161–67.

D. T. Swift-Hook and A. E. F. Gick:Weld. J., 1973, vol. 52, pp. 492s-99s.

P. Jhaveri, W. G. Moffatt, and C. M. Adams, Jr.:Weld. J., 1962, vol. 41, pp. 12s-16s.

H. Ghent, C. E. Hermanee, H. W. Kerr, and A. B. Strong: Arc Physics and Weld Pool Behavior, Conference Proceedings, The Welding Institute, Cambridge, U.K., 1979.

R. Trivedi and S. R. Srinivason:J. Heat Transfer, 1974, vol. 96, pp.427–28.

V. Pavelic, R. Tanbakuchi, O. A. Uyehara, and P. S. Myers:Weld. J., 1969, vol. 48, pp.295s-305s.

E. Friedman:J. Pressure Vessel Technol., 1975, vol. 97J, pp. 206–13.

E. Friedman:Nuclear Metall., 1976, vol. 20, pp. 1160–70.

Y. Sharir, A. Grill, and J. Pelleg:Metall. Trans. B, 1980, vol. 1 IB, pp. 257–65.

N. Shamsundar and E. M. Sparrow:J. Heat Transfer, 1975, vol. 97, pp. 333–40.

E. A. Mizikar:Trans. TMS-AIME, 1967, vol. 239, pp. 1947–1753.

W. Kaplan:Operational Methods for Linear Systems, p. 49, Addison-Wesley, 1962.

J. P. Holman:Heat Transfer, 4th ed., p. 342, McGraw-Hill, 1976.

M. C. Flemings:Solidification Processing, p. 35, McGraw-Hill, 1974.

Aluminum, K. R. Van Horn, ed., vol. I, pp. 8 and 17, ASM, 1967.

Aluminum Standards and Data, 4th ed., p. 40, the Aluminum Association, 1976.

S. Kou, T. Kanevsky, and S. Fyfitch: Weld. J., in press.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kou, S. Simulation of Heat Flow During the Welding of Thin Plates. Metall Trans A 12, 2025–2030 (1981). https://doi.org/10.1007/BF02644171

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02644171