Abstract

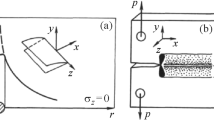

In order to distinguish between “true” transgranular stress-corrosion cracking (T-SCC) and the “chemical embrittlement” previously described for Cu3Au single crystals (Bakish,AIME Trans., 1957), copper-25 atomic percent gold single crystals were subject to constant deflection (a) while immersed in aqueous ferric chloride or (b) in air after undergoing stress-free corrosion for 10 and 30 days in aqueous ferric chloride. In the conventional stress-corrosion testing mode carried out at the corrosion potential and at applied anodic and cathodic overpotentials, SEM observation and microprobe analysis revealed that characteristic T-SCC fracture surfaces were produced without the occurrence of massive dealloying, at least over a 0.1 micrometer depth. For bending tests in air following stress-free corrosion at the corrosion potential, a 30-day sample was completely converted into a brittle, virtually pure gold “sponge” while retaining the external shape and orientation of the original alloy single crystal. The fracture surface of this sample revealed relatively flat facets separated by irregularly serrated steps, as are seen in conventional cleavage. However, the surface is porous with a mean pore size of ∼0.1 micrometer. For the 10-day sample, bending produced multiple cracks in a massively dealloyed layer (gold-rich sponge). Several of these cracks propagated into the unattacked, normally ductile alloy for distances up to ∼20 micrometers. Interpretation of these results leads to an alternative explanation for the “chemical embrittlement” previously observed and offers significant new insights on the mechanisms of T-SCC.

Similar content being viewed by others

References

R. Bakish:Trans. AIME, 1957, vol. 209, pp. 494–95.

K. Sieradzki and R.C. Newman:Philos. Mag., 1985, vol. 51, pp. 95–132.

B.D. Lichter, T.B. Cassagne, W. F. Flanagan, and E.N. Pugh:Microstructural Science, 1985, vol. 13, pp. 361–78.

C. Edeleanu:Physical Metallurgy of Stress Corrosion Fracture, Inter- science, New York, NY, 1959, pp. 79–98; C. Edeleanu and A. J. Forty:Philos. Mag., I960, vol. 5, pp. 1029-40.

A. J. Bursle and E. N. Pugh:Environment-Sensitive Fracture of Engi- neering Materials, TMS-AIME, Warrendale, PA, 1979, pp. 18–47.

J. A. Beavers and E. N. Pugh:Metall. Trans. A, 1980, vol. 11A, pp. 809–19.

E. N. Pugh:Atomistics of Fracture, NATO Conference Series VI, Plenum Press, New York, NY, 1983, vol. 5, pp. 997–1010.

J. L. Nelson: Ph.D. Thesis, University of Illinois at Champaign-Urbana, IL, 1976.

R. Liu, N. Narita, C. Altstetter, H. Birnbaum, and E. N. Pugh:Metall. Trans. A, 1980, vol. 11A, pp. 1563–73.

E.I. Meletis and R. F. Hochman:Corros. Sci., 1984, vol. 24, pp. 843–62.

S.P. Lynch:Scripta Metall., 1984, vol. 18, pp. 321–26.

T. B. Cassagne: M.S. Thesis, Vanderbilt University, Nashville, TN, 1985.

T. B. Cassagne, W. F. Flanagan, and B. D. Lichter: Vanderbilt University, Nashville, TN, unpublished research, 1985.

E. Kuramoto and D. P. Pope:Philos. Mag., 1976, vol. 33, pp. 675–83.

R. Bakish and W. D. Robertson:Acta Metall., 1956, vol. 4, pp. 342–51.

H.W. Pickering and P. R. Swann:Corrosion, 1963, vol. 19, pp. 373t-89t.

K. Hashimoto, T. Goto, W. Suetaka, and S. Shimodaira:Trans. JIM, 1965, vol. 6, pp. 107–13.

W. D. Robertson and A. S. Tetelman:Strengthening Mechanisms in Solids, American Society for Metals, Metals Park, OH, 1962, pp. 217–52.

H.W. Pickering:Corrosion, 1969, vol. 25, pp. 289–90.

A. Paskin, K. Sieradzki, D. K. Som, and G. J. Dienes:Acta Metall., 1982, vol. 30, pp. 1781–88 ; ibid., 1983, vol. 31, pp. 1253-65.

A. J. Forty:Physical Metallurgy of Stress Corrosion Fracture, Inter- science, New York, NY, 1959, pp. 99–120.

J. M. Davidson, C. M. Austin, and M. L. Robinson:Metall. Trans. A, 1983, vol. 14A, pp. 1516–18.

K. Sieradzki:Acta Metall., 1982, vol. 30, pp. 973–82.

C.J. McMahon and M. Cohen:Acta Metall., 1965, vol. 13, pp. 591–604.

J. R. Rice and R. Thomson:Philos. Mag., 1974, vol. 29, pp. 73–97.

Rui-Huan Zhao and J. C. M. Li: “Dynamic Emission of Dislocations from a Moving Crack,”J. of Engineering Materials and Technology, 1985, vol. 107, pp. 277–81.

J. S. Kim: Ph.D. Thesis, Vanderbilt University, Nashville, TN, 1985.

Author information

Authors and Affiliations

Additional information

Formerly with the Department of Mechanical and Materials Engineering, Vanderbilt University, Nashville, TN

Rights and permissions

About this article

Cite this article

Cassagne, T.B., Flanagan, W.F. & Lichter, B.D. On the failure mechanism of chemically embrittled Cu3Au single crystals. Metall Trans A 17, 703–710 (1986). https://doi.org/10.1007/BF02643991

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643991