Abstract

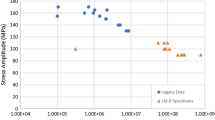

Measurement of the threshold for fatigue macrocrack propagation, ΔKo, in a number of aluminum alloys has shown an increase with grain size and decrease with increase in strength as with steels. The results are not primarily due to environmental enhancement of fatigue crack growth because an even larger variation in ΔKo with microstructural change is noted at 77 K than at 300 K. In particular, ΔKo of high purity 2124-T4 increases much more on cooling from 300 to 77 K than does ΔKo of 2024-T4. It is suggested that ΔKo is determined by the stress necessary to operate a dislocation source near the crack tip. A Frank-Read type source is proposed for 2024-T4 with constituent particles acting as pinning points while double cross-slip, a thermally activated process, is proposed for the source in high purity 2124-T4.

Similar content being viewed by others

References

T. Yokobori, A. T. Yokobori, Jr., and A. Kamei:Int. J. Fract., 1975, vol. 11, p. 781;ibid., 1976, vol. 12, p. 519; T. Yokobori, S. Konosu, and A. T. Yokobori, Jr.:Fracture 1977, Univ. Waterloo, vol. 1, p. 665, 1977; T. Yokobori and T. Yokobori:Jpn. Inst. Met., 1978, vol. 42, p. 88; A. T. Yokobori, Jr.:Int. J. Fract., 1978, vol. 14,pp.R137,R315.

K. Sadananda and P. Shihinian:Int. J. Fract., 1977, vol. 13, p. 585.

J. D. Harrison:Met. Constr. Brit. Weld. J., March 1970, vol. 2, pp. 93–98.

R. O. Ritchie,J. Eng. Mater. Technol., Trans. ASME, Ser. H, 1977, vol. 99, p. 195.

H. Suzuki and A. J. McEvily:Metall. Trans. A, 1979, vol. 10A, p. 475.

J. Masounave and J. P. Bailon:Scr. Metal., 1976, vol. 10, p. 165.

S. Taira, K. Tanaka, and M. Hoshina:ASTM STP 675, J. T. Fong, ed., ASTM, Philadelphia, PA, 1980, pp. 135–73.

E. K. Priddle:Scr. Metall., 1978, vol. 12, p. 49.

P. E. Irving and C. J. Beevers:Mater. Sci. Eng., 1974, vol. 14, p. 229.

R. J. Cooke, P. E. Irving, G. S. Booth, and C. J. Beevers:Eng. Fract. Mech., 1975, vol. 7, p. 69; P. E. Irving and A. Kurzfeld:Metall. Sci., 1978, vol. 12, p. 495.

B. R. Kirby and C. J. Beevers:Fatigue Eng. Mater. Struct., 1979, vol. 1, p. 203.

M. E. Fine: “Thresholds for Fatigue Failure”,Trans. Jpn. Inst. Met., 1981, In press.

S. Ikeda, Y. Izumi, and M. E. Fine:Eng. Fract. Mech., 1977, vol. 9, p. 123; Y. Izumi and M. E. Fine:ibid, 1979, vol. 11, p. 791.

R. E. Sanders, Jr., W. L. Otto, Jr., and R. J. Bucci: Air Force Materials Lab Tech. Rept. 79-4131, Sept. 1979, Wright-Patterson AFB, OH.

P. K. Liaw and J. Baker:Rev. Sci. Inst., 1979, vol. 50 no. 12, p. 1590.

P. Boisson, J. Petit, and C. Gase:Mem. Sci. Rev. Metall., 1977, vol.74, p. 427.

U. F. Kochs:J. Eng. Mater, and Technol., Trans. ASME, Ser. H. 1976, vol. 98, p. 76.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McKittrick, J., Liaw, P.K., Kwun, S.I. et al. Threshold for fatigue macrocrack propagation in some aluminum alloys. Metall Trans A 12, 1535–1539 (1981). https://doi.org/10.1007/BF02643701

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02643701