Abstract

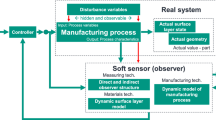

This paper is aimed at presenting the current status of the knowledge and the use of chip control in machining, with a view to identifying the further work required for total chip control in unmanned systems. The results of an extensive survey on chip control covering over 160 published works since 1900 have been classified and summarised in 11 chip control-associated keyword groups. A critical review of the present status of research and future directions are then presented. This highlights the need for developing knowledge-based systems on the basis of a coding and classification system and the machinability data banks featuring predictive machining theories. An extension to this off-line processing facility in the proposed knowledge-based system would be the use of an on-line sensor-based chip form monitoring technique.

Similar content being viewed by others

Bibliography

F. W. Taylor, ‘On the Art of Cutting Metals’,Trans. ASME 28, pp. 31–350 (1907).

A. L. Deleeuw,Metal Cutting Tools, McGraw-Hill Book Company, New York, 1922.

H. Klopstock, ‘Recent Investigations in Turning and Planning and a New Form of Cutting Tool, Trans. ASME47, pp. 345–377 (1925).

E. G. Herbert, ‘Cutting Tools Research Committee Report on Machinability,’Proc. Inst. Mech. Eng. Part V, pp. 19–21 (1928).

H. Hemscheidt, ‘Chip Types and Chip Breakers for Cutting Steel with Carbides’,TZ Fur Praktische Metallbearbeitung 51 (13/14), (15/16), (17/18), (19/20) (1941).

E. Almdale, ‘Chip Control when Machining Steel with Carbide,’Tool & Die Journal IX, pp. 105–109 (1943).

J. B. Armitage and A. O. Schmidt, ‘An Investigation of Radial Rake Angles in Face Milling’,Trans. ASME 66, pp. 633–643 (1944).

G. I. Kiselev, ‘Results of a Study of the Performance of a Dynamical Chip Breaker’,Stankii Instrumient 22 (4), (April 1951).

E. K. Henriksen,Chip Breakers, National Machine Tool Builders Association, Cleveland, Ohio, USA, 1953.

L. V. Colwell, ‘Predicting the Angle of Chip Flow for Single-Point Cutting Tools’,Trans. ASME 76 (2), pp. 199–204 (1954).

E. K. Henriksen, ‘Balanced Design Will Fit the Chip Breaker to the Job: Chip Breaker Dimensions are Critical in Taming Chips’,American Machinist 98 (4), pp. 118–124 (1954).

B. L. Ten Horn and R. A. Schuermann, ‘Chip Control, How to Determine Tool Feed to Obtain Desirable Chip Form?’,Tool Engineer 32 (4), pp. 37–44 (1954).

E. K. Henriksen, ‘Findings and Directions in Chip Breakers Research’,Proc. 23rd Annual Meeting of ASTE, Los Angeles, California (14–18 March 1955).

B. Anon, ‘Soviets Claim New Cutting Tool Geometry Eliminates Vibration and Multiplies Tool Life 80–200 Times’,American Machinst, pp. 190–194 (12 March 1956).

L. Fine, ‘Chip Control. Part 1. Grooves in Carbide-tipped Turning Tool’,Aircraft Production, pp. 156–161 (April 1956).

L. Fine, ‘Chip Control. Part 2. Unconventional Chip Control Grooves’,Aircraft Production, pp. 200–205 (May 1956).

H. Takeyama and E. Usui, ‘The Effect of Tool-Chip Contact Area in Metal Machining’,Trans. ASME 80, pp. 1089–1096 (1958).

B. T. Chao and K. J. Trigger, ‘Controlled Contact Cutting Tools’,Trans. ASME 81 (2), pp. 139–151 (1959).

N. G. Abduladze, ‘Length of Plastic Contact on Rakeface During Metal Cutting,’Trudi-Gruz, Politech. Inst. Tbilisi,29, p. 25 (1959).

M. I. Klushin, ‘Determination of the Contact Zone between Chip and Rake Face and the Pressure in this Zones,’Stankii Instrumient 31, pp. 22–23 (1960).

W. B. Heginbotham and S. L. Gogia, ‘Metal Cutting and the Built-Up Nose,’Proc. Inst. Mech. Eng. 175 (18), pp. 892–917 (1961).

K. J. Trigger and A. Bhattacharyya, ‘Performance of Controlled Contact Tools’,Journal of Inst. Engrs. (India) 63 (Nov. 1962).

W. Johnson, ‘Some Slip-line Fields for Swaging or Expanding, Indenting, Extruding and Machining for Tools with Curved Dies,’Int. J. Mech. Sci. 4, pp. 323–347 (1962).

V. M. Lutov, ‘Selecting the Optimum Size of Chip-breaking Grooves,’Machines and Tooling 33 (7), pp. 27–30 (1962).

P. L. B. Oxley, ‘An Analysis for Orthogonal Cutting with Restricted Tool-Chip Contact’,Int. J. Mech. Sci. 4, pp. 129–135 (1962).

V. I. Sisoev,Fundamentals of Metal Cutting and Cutting Tools, Mashigiz, Moscow, 1962.

K. Nakayama, ‘Chip Curl in Metal Cutting Process’,Bulletin of the Faculty of Engineering, Yokohama National Univ. 11, pp. 1–13 (1962).

K. Nakayama, ‘A Study on Chip Breaker’,Bulletin of JSME 5 (17), pp. 142–150 (1962).

E. Usui and M. C. Shaw, ‘Free Machining Steel-IV: Tools with Reduced Contact Length’,Trans ASME, pp. 89–101 (1962).

K. Hoshi and E. Usui ‘Wear Characteristics of Carbide Tools with Artificially Controlled Tool-Chip Contact Length’,Proc. 3rd Int. MTDR Conf. pp. 121–128 (September 1962).

K. Nakayama, ‘Pure Bending Test of Chip—An Approach to the Prediction of Cutting Force’,Bulletin of the Faculty of Engineering, Yokohama National Univ.,12, pp. 1–14 (1963).

N. H. Cook, P. Jhaveri and N., Nayak, ‘The Mechanism of Chip Curl and its Importance in Metal Cutting’,Trans. ASME, pp. 374–380 (1963).

V. N. Poduraev and A. M. Bezborodov, ‘Using Self-exited Vibrations for Chip Breaking,’Machines and Tooling 34 (1), pp. 19–22 (1963).

E. Usui and K. Hoshi, ‘Slip-line Fields in Metal Machining Which Involve Centered Fans’,Proc. Int. Prod. Eng. Res. Conf. ASME, Pittsburgh, pp. 61–71 (September 1963).

M. C. Shaw, ‘Resumé and Critique of Papers in Part One’,Proc. Int. Prod. Eng. Res. Conf. ASME, Pittsburgh, pp. 3–17 (September 1963).

G. V. Stabler, ‘The Chip Flow Law and its Consequences’,Proc. 5th Int. MTDR Conf., pp. 243–251 (September 1964).

A. J. Pekelharing, ‘Why and How Does the Chip Curl and Break?,’Annals of the CIRP 12, pp. 144–147 (1964).

E. Usui, K. Kikuchi and K. Hoshi, ‘The Theory of Plasticity Applied to Machining with Cut-Away Tools’,Trans. ASME, pp., 95–104 (May 1964).

H. Kudo, ‘Some New Slip-line Solutions for Two-dimensional Steady-State Machining,”Int. J. Mech. Sci. 7, pp. 43–55 (1965).

W. Johnson and F. U. Mahtab, ‘Upper Bounds or Restricted Edge Machining: Paper I’,Proc. 6th Int. MTDR Conf., pp. 447–462 (1965).

W. Johnson and F. U. Mahtab, ‘Some Solutions using Slip-line Fields and the Methods of Upper Bounds for Milling, Turning and Boring: Paper II’,Proc. 6th Int. MTDR Conf., pp. 463–485 (1965).

W. Johnson, ‘Further Rotational Configurations—Straight Straight Starting Slip-lines: Paper III’Proc. 6th Int. MTDR Conf., pp. 487–490 (1965).

I. I. Shilin and K. G. Sadolevskaya, ‘Chip Breaking by Interrupted Feed’,Machines and Tooling 36, pp. 30–32 (1965).

A. F. Vlasov, ‘Pneumatic Methods of Removing Chips and Dust’, (MTIRA Translation-T204),Mashino stroitel, pp. 33–38 (1965).

J. K. Russell and R. H. Brown, ‘Deformation During Chip Formation’,Trans. ASME, pp. 53–56 (1965).

G. F. Dzanashvili, ‘Chip Breaking by Interrupted Cutting,’Vestnik Mashinostroeniya, (7), pp. 72–73 (1965).

S. Y. Lo, U. Lode and E. J. A. Armarego, ‘Experiments with Controlled Contact Tools’,Int. J. MTDR,6, pp. 115–127 (1966).

M. Okoshi and K. Kawata, ‘Effects of the Curvature on Work Surface on Metal Cutting’,Annals of the CIRP 15, pp. 393–403 (1967).

W. Johnson, ‘Cutting with Tools Having a Rounded Edge—Some Theoretical Consideration’,Annals of the CIRP 14, pp. 315–319 (1967).

P. F. Ostwald, ‘Dynamic Chip Breaking: Can it Overcome the Surface Finish Problem?’, ASTME Paper MR67-228 (1967).

G. R. Ponkshe, ‘A New Explanation of the Phenomenon of Chip Curling During Machining’,Trans. ASME, pp. 376–379 (1967).

C. Rubenstein, ‘The Mechanism of Orthogonal Cutting with Controlled Contact Tools’,Int. J. MTDR 8, pp. 203–216 (1968).

J. A. Bailey and G. Boothroyd, ‘Critical Review of Some Previous Work on the Mechanics of the Metal Cutting Process’,Trans. ASME, pp. 54–62 (1968).

P. F. Ostwald and J. E. Shamblin, ‘Effects of Dynamic Chip Breaking upon Surface Micro Geometry and Free-Chip Dimension,’Trans. ASME 90, pp. 71–78 (1968).

C. Stickforth, ‘Moderne Methoden der Handhabung von Produktions—abfallen’,Technischez Zentralblatt fur praktische Metallbearbeitung 62 (12), pp. 633–635 (1968).

I. Ham and A. Bhattacharyya, ‘Design of Single Point Cutting Tools-Use of Metal Cutting Theory’,Ch. 4, Design of High Production Cutting Tools, ASTME, Michigan, pp. 99–115 (1969).

C. C. Dawe and C. Rubenstein, ‘Analysis of Chip Curvature’,Proc. 10th Int. MTDR Conf., pp. 283–298 (1969).

G. E. Kane, E. J. McTamany and J. F. Peritore, ‘A Systematic Approach to the Breaking of Chips’,ASTME Paper, MR69-174 (1969).

M. M. Barash and W. J. Schoech, ‘A Semi-Analytical Model of the Residual Stress Zone in Orthogonal Machining’,Proc. 11th Int. MTDR Conf., pp. 603–613 (1970).

W. Johnson, R. Sowerby and J. B. Haddow,Plane-Strain Slip-line Fields: Theory and Bibliography, Edward Arnold (Publishers) Ltd., London, 1970.

N. Shinozaki and H. Hirota, ‘Chip Breaking by Rolling Tool’, SME Paper MR70-250 (1970).

H. Takeyama, H. Sekiguchi and K. Takada, ‘One Solution for Chip Hazard in Turning-Study on Automatic Programming for Numerically Controlled Machines (1st Report)’,Journ. Jap. Soc. for Prec. Engg. 36(2), pp. 150–156, (1970).

C. Spaans, ‘A Systematic Approach to Three Dimensional Chip Curl, Chip Breaking and Chip Control’, SME Paper 70-241 (1970).

M. Y. Friedman and E. Lenz, ‘Investigation of the Tool-Chip Contact Length in Metal Cutting’,Int. J. MTDR 10, pp. 401–416 (1970).

G. L. Khaet and G. F. Vasilyuk, ‘Effect of a Rounded Cutting Edge on Cemented Carbide Tools’,Russian Eng. Journal L (4), pp. 81–84 (1970).

C. Spaans and P. F. H. J. Van Geel, ‘Break Mechanisms in Cutting with a Chip Breaker’,Annals of the CIRP 18, pp. 87–92 (1970).

R. Komanduri, ‘Some Aspects of Machining with Negative Rake Tools Simulating Grinding’,Int. J. MTDR 11, pp. 223–232 (1971).

G. E. Kane, ‘The Effect of Tool Geometry on Chip Breaking’,Proc. 1st Int. Conf. on Cemented Carbide, SME, pp. 227–238 (February 1971).

C. Spaans, ‘A Comparison of an Ultrasonic Method to Determine the Chip/Tool Contact Length with Some Other Methods’,Annals of the CIRP 19, pp. 485–490 (1971).

C. Spaans, ‘The Fundamentals of Three-Dimensional Chip Curl, Chip Breaking and Chip Control’, Doctoral Thesis, TH Delft (1971).

W. K. Luk, ‘The Direction of Chip Flow in Oblique Cutting’,Int. J. Prod. Res. 10 (1), pp. 67–76 (1972).

K. Nakayama, ‘Origins of Side Curl of Chip in Metal Cutting’,Bull. Japan Soc. of Prec. Engg. 6 (3), pp. 99–101 (1972).

M. O. Noodel'man, ‘Effect of Wear on Chip-Breaker-Grooved Tools’,Russian Eng. Journal,L11 (8), pp. 66–67 (1972).

R. L. Kaul and C. K. Singh, ‘Some Investigations on Chip Curl and Chip Breaker’,Proc. 5th AIMTDR Conf., Univ. Roorkee, India, pp. 85–89 (April 1972).

B. K. Nagpal and C. S. Sharma, ‘Investigation of Tool-Chip Contact Length in Flooding and Hi-Jet methods of Cutting Fluid Application’,Proc. 5th AIMTDR Conf., Univ. Roorkee, India, pp. 17–23 (April 1972).

D. G. Jones and J. F. McCreery, ‘A Study of Preformed Chip Control Devices in Throwaway Carbide Inserts’, SME Technical Paper MR73-215, 1973.

G. Boothroyd and L. E. Reinhart, ‘Effect of Chip Forming Devices on Tool-wear in Metal Cutting’,Proc. 1st North Amer. Met. Working Res. Conf., Hamilton, Ontario2, pp. 13–33 (May 1973).

B. Sperandio, ‘Chip Control—Design Innovations Which Increase the Chip Control Range and Capacity of Indexable Inserts’, SME Technical Paper MR73-904 (1973).

B. Worthington and A. H. Redford, ‘Chip Curl and the Action of the Groove Type Chip Former’,Int. J. MTDR 13, pp. 257–270 (1973).

K. Minato, T. Teshima and Y. Kakino, ‘A Study on the Chip-Excluding (1st Report)—An Estimated Method of the Facility of Chip-Excluding with Air’,Bull. Japan Soc. of Prec. Engg. 8 (1), pp. 21–22 (1974).

N. I. Tashlitskii and V. S. Kushner, ‘Cemented—Carbide Tools for Finish—Turning Steels’,Russian Eng. Journal 54 (5), pp. 59–62 (1974).

B. Worthington, ‘Surface Integrity, Cutting Forces and Chip Formation When Machining with Double Rake Angle Tools’,Int. J. MTDR 14, pp. 279–295 (1974).

D. F. Pearce and D. B. Richardson, ‘Machining Stability using Controlled Contact Tools’,Int. J. Prod. Res. 13 (1), pp. 75–82 (1975).

J. S. Bator, ‘Power Reduction Through Efficient Chip Control’Cutting Tool Engineering, pp. 4–8 (July/August 1975).

G. Boothroyd, ‘Chip Control: (Ch. 8 of Book)—Fundamentals of Metal Machining and Machine Tools, McGraw Hill Book Company, 1975.

B. Worthington, ‘The Effect of Rake Face Configuration on the Curvature of the Chip in Metal Cutting’,Int. J. MTDR 15, pp. 223–239 (1975).

J. W. Heaton, ‘The Development of a Heavy Duty Tooling System’, SME Technical Paper TE 75-404, 1975.

C. A. Van Luttervelt, ‘Chip Formation in Machining Operation at Small Diameter’,Annals of the CIRP 25 (1), pp. 71–76 (1976).

S. Kaldor,Investigation of Chip Breaking, MSc Thesis, Technion—Israel Institute of Technology, Haifa, Israel (1976).

I. G. Mansyrev, ‘Kinematic Chip Breaking’,Stanki i Instrumient 47 (2), pp 32–34 (1976).

B. Worthington, ‘The Operation and Performance of a Groove-type Chip forming Device’,Int. J. Prod. Res. 14 (5), pp. 529–558 (1976).

D. F. Pearce, ‘Dynamic Chip formation when Machining with Restricted Contact Tools’,Proc. 18th Int. MTDR Conf., pp. 339–405 (1977).

D. F. Pearce and D. B. Richardson, ‘Improved Machining Capability using Controlled Contact Tools’,CME, pp. 55–57 (Jan. 1977).

P. K. Wright, ‘Applications of theExperimental Methods used to Determine Temperature Gradients in Cutting Tools’,Proc. Australian Conf. on Manuf. Engineering, pp. 145–149 (Aug. 1977).

R. L. Woodward, ‘Determination of Plastic Contact Length Between Chip and Tool in Machining’, Technical Briefs,Trans. ASME 99, pp. 802–804 (1977).

D. B. Richardson and D. F. Pearce, ‘Measurement of Dynamic Cutting Force when using Restricted Contact Tools’,Proc. 18th Int. MTDR Conf., pp. 391–397 (1977).

F. O. Rasch and K. Tonnessen, ‘Tool Failure and Chip Form as Restriction when Selecting Cutting Data’,Annals of the CIRP 25 (1), pp. 45–48 (1977).

J. G. Horne, E. D. Doyle and D. Tabor, ‘Direct Observation of the Chip/Tool Interface’,Proc. 5th North Amer. Metal Working Res. Conf., pp. 237–241 (1977).

N. K. Lavrov, ‘Analysis of Swarf Breaking Devices’,Russian Eng. Journal 57 (10), pp. 42–44 (1977).

K. Nakayama and M. Arai, ‘Roles of Brittleness of Work Material in Metal Cutting’, Proc. Int. Symposium on Influence of Metallurgy on Machinability of Steel, Tokyo, Japan, pp. 421–432 (Sept. 1977).

N. Gane, ‘Chip Fracture During Metal Machining’,Proc. Australian Conf. on Manufacturing Engineering, pp. 127–131 (1977).

P. Dewhurst, ‘The Mechanics of Machining—An Investigation of the Primary Mode of Deformation,’Departmental Report, Mech. and Aeronautical Eng. Dept., University of Salford, Salford UK (1978).

C. J. Kotval and M. M. Barash, ‘Reducing the Temperture at Tool-Chip-Work Contact by Changing the Effective Thermal Conductivity of the Tool,’Trans. ASME 10, pp. 387–389 (1978).

P. Dewhurst, ‘On the Non-Uniqueness of the Machining Process’,Proc. Roy. Soc., London,A 360, pp. 587–610 (1978).

J. G. Horne, ‘A New Model for Initial Chip Curl in Continuous Cutting’,Int. J. Mech. Sci. 20, pp. 739–745 (1978).

K. Nakayama and M. Ogawa, ‘Basic Rules on the Form on Chip in Metal Cutting’,Annals of the CIRP 27 (1), pp. 17–21 (1978).

N. I. Tashlitskii et al, ‘Finish Turning of Interactable Alloys using Tools with a Finishing Edge’,Russian Eng. Journal 58 (8), pp. 43–44 (1978).

J. M. Challen and P. L. B. Oxley, ‘An Explanation of the Different Regimes of Friction and Wear using Asperity Deformation Models’,Wear 53, pp. 229–243 (1979).

P. Dewhurst, ‘The Effect of Chip Breaker Constraints on the Mechanics of the Machining Process’,Annals of the CIRP 28 (1), pp. 1–5 (1979).

A. Ber, S. Kaldor and E. Lenz, ‘New Concept in Chip-Breaker Design Leads to a Wider Range of Chip-Breaking’, SMT Technical Paper MR79-307 (1979).

S. Kaldor, A. Ber and E. Lenz, ‘On the Mechanism of Chip Breaking’,Trans. ASME 101, pp. 241–249 (1979).

W. Kluft, W. König, C. A. Van Luttervelt, K. Nakayama and A. J. Pekelharing, ‘Present Knowledge of Chip Control’,Keynote Paper, Annals of the CIRP 28 (2), pp. 441–455 (1979).

E. Lundgren, “Optimising Performance of Cutting Edge’,Proc. Conf. New Frontiers in Tool Materials, Cutting Techniques and Metal Forming 2 (Session II, Paper 1) (1979).

N. Gane, ‘Chip Fracture During the Machining of Brass’,Proc. 4th Tewksbury Symposium, Melbourne (Feb. 1979).

B. Worthington and M. H. Rahman, ‘Predicting Breaking with Groove Type Breakers’,Int. J. MTDR 19, pp. 121–132 (1979).

Y. Z. Zhang, ‘Chip Curl, Chip Breaking and Chip Control of the Difficult-to-Cut Materials’,Annals of the CIRP 29 (1), pp. 79–83 (1980).

P. K. Wright, S. P. McCormick and T. R. Miller, ‘Effect of Rake Face Design on Cutting Tool Temperature Distribution’,Trans. AMSE 102, pp. 123–128 (1980).

R. J. Grieve and A. C. Thaker, ‘Some Aspects of Chip Control in Profile Boring’,Int. J. Prod. Res. 18, pp. 539–558 (1980).

K. Nakayama and M. Arai, ‘The Breakability of Chip in Metal Cutting’,Proc. Int. Conf. on Manuf. Eng., Melbourne, Australia, pp. 6–10 (1980).

R. N. Mittal, B. L. Juneja and G. S. Sekhon, ‘A Solution of the Oblique Controlled Contact Continuous Cutting Problems’,Int. J. MTDR 20, pp. 211–221 (1980).

A. H. Redford, ‘The Effect on Cutting Tool-wear of Various Types of Chip Control Device’,Annals of the CIRP 29 (1), pp. 67–71 (1980).

A. Ber, S. Kaldor and E. Lenz, ‘A Chip Breaker Design’, Report, Technion—Faculty of Mech. Engg., Haifa, Israel, 1980.

S. Ramalingam and P. V. Desai, ‘Tool-Chip Length in Orthogonal Machining’,ASME Paper 80, WA/Prod. 23, 1980.

K. Nakayama, M. Arai and T. Kondo, ‘Cutting Tools with Curved Rake Face—A Means for Breaking Thin Chips’,Annals of the CIRP 30 (1), pp. 5–8 (1981).

R. G. Davydova, ‘Chip Breaking Device for Turning’,Soviet Eng. Research 2 (7), pp. 72–74 (1982).

R. N. Mittal and B. L. Juneja, ‘Effect of Stress Distribution on the Shear Angle in Controlled Contact Orthogonal Cutting’,Int. J. MTDR 22 (2), pp. 87–96 (1982).

L. De Chiffre, ‘Cutting Tools with Restricted Contact’,Int. J. MTDR 22 (4), pp. 321–332 (1982).

Fagersta Steels (Pty) Ltd., South Africa, ‘Turning with Modern Indexable Insert Tooling’,South African Machine Tool Review 15 (5), pp. 9–15 (May 1982).

K. Uegami and K. Tamamura, ‘Method of Determining the Actual Form of the Tool Edge from Chips’,Memoris of Fac. Eng., Osaka City University, pp. 1–24 (1982).

P. L. B. Oxley, ‘Machinability: A Mechanics of Machining Approach’ (Invited paper to ASME in honour of F. W. Taylor). Published byASME in ‘On the Art of Cutting Metals— 75 Years Later: A Tribute to F. W. Taylor’,PED 7, pp. 37–83 (1982).

S. Nakamura, G. J. Wuebbling and J. D. Christopher, ‘Chip Control in Turning’,Proc. Int. Tool and Manuf. Eng. Conf., SME, USA, pp. 159–177 (May 1982).

K. Gettleman (Editor Interviewer) and K. H. McKee (Interviewee—Manager, Engineering, Carboloy Systems Dept. Michigan, USA), ‘New Groove Geometries Boost Insert Performance’, Interview Summary byModern Machine Shop, pp. 58–63 (Feb. 1983).

I. Yellowley, ‘The Utilisation of Restricted Rake Face Contact Turning Tools’,Annals of the CIRP 32 (1), pp. 75–78 (1983).

J. M. Challen, ‘Slip-line Fields (for Polishing) with a Cylindrically Shaped Abrasive Grit’, Research Report No. 1983/AM/1, School of Mech. & Ind. Engineering, University of NSW, Sydney (March 1983).

H. Beran, ‘Development of Moulded Chip Breakers in Indexable Inserts’,Aust. Machinery & Prod. Engg., pp. 17–18 (April 1983).

C. A. Brown, ‘A Practical Method for Estimating Machining Forces from Tool-Chip Contact Areas’,Annals of the CIRP 32 (1), pp. 91–95 (1983).

C. A. Brown (University of Vermont and State Agricultural College), ‘Material Behaviour During Chip Formation’, Diss. Abstr. Int.,44 (4), p. 186 (October 1983).

M. M. Elkhabeery, ‘A Study of Some Aspects of Metal Machining Using Controlled Contact Length Tools’, Diss. Abstr. Int.,44 (5), p. 206 (November 1983).

K. Nakayama, ‘Chip Control in Metal Cutting’,Bull. Japan. Soc. of Prec. Eng. 18 (2), pp. 97–103 (1984).

A. K. A. Radwan and R. M. Taher, ‘Some Observations on Machining Steel using Tools with Step-Type Chip Breakers’,Proc. North Amer. Met. Work. Res. Conf., pp. 367–371 (1984).

P. K. Venuvinod, W. L. Lau and C. Rubenstein, ‘Analysis of the Life of Controlled Contact Tools via Flank Contact Temperature Estimation’,Annals of the CIRP 33 (1), pp. 55–59 (1984).

C. Y. Jiang, Y. Z. Zhang and Z. J. Chi, ‘Experimental Research of the Chip Flow Direction and its Application to the Chip Control’,Annals of the CIRP 33 (1), pp. 81–84 (1984).

Kennametal Inc., ‘Chip Control Research Through High-Speed Motion Analysis’,Carbide Tool Journal 16 (3), pp. 21–23 (May–June 1984).

H. K. Toenshoff, H. Winkler and M. Patzke, ‘Chip Formation at High-Cutting Speeds’, Proc. Conf. on High Speed Machining, New Orleans, Louisiana, USA (9–14 Dec. 1984),ASME Paper PED 12, pp. 95–100 (1984).

Andrew de Vica, ‘Simple Vision System Monitors Tools and Swarf’,Prod. Engineer 63 (2), pp. 24–25 (Feb. 1984).

O. Bjorke, ‘Towards Integrated Manufacturing Systems—Manufacturing Cells and Their Subsystems’,Robotics and Comp. Integ. Manuf. 1 (1), pp. 3–19 (1984).

M. M. Elkhabeery and J. A. Bailey, ‘Surface Integrity in Machining Solution—Treated and Aged 2024 Aluminium Alloy Using Natural and Controlled Contact Length Tools. I— Unlubricated Conditions’,J. Eng. Mater. Technol; Trans. ASME 106 (2), pp. 152–160 (April 1984).

J. A. Bailey and M. M. Elkhabeery, ‘Surface Integrity in Machining Solution—Treated and Aged 2024 Aluminium Alloy Using Natural and Controlled Contact Length Tools. II —Lubricated Conditions’,J. Eng. Mater. Technol; Trans. ASME 106 (2), pp. 161–166 (April 1984).

R. Komanduri and M. Lee, ‘The Ledge Tool: A New Cutting Tool Insert’,J. Ind. Trans. ASME 107, pp. 99–106 (1985).

S. Yamamoto, T. Araki and H. Nakajima, ‘Chip Disposability and Tool Wear in Ferritic Steels Mixed with Martensite’,Tetsu-to-hagane (J. Iron Steel Inst. Japan)71 (6), pp. 756–763 (Apr. 1985) (in Japanese).

S. Yamauchi, A. Komura and M. Yamamoto, ‘A Study on Surface Finishing Using a High Feed-Rate Turning-Disposal of Chips and Finishing Surface’,Hitachi Zosen Tech. Rev. 46 (3), pp. 48–60 (Sept. 1985) (in Japanese).

S. Shiratori, ‘Trends in the Geometry of Machining Tools’,Metal Technol. (Japan) 55 (5), pp. 19–27 (May 1985) (in Japanese).

P. K. Venuvinod, “On the Formation of a Unique type of Continuous Chips Resembling Transient Chips’,Proc. First Int. Metal Cutting Conf., Guanzhou, P.R. China (Mar. 1983); China Academic Publishers, pp. 177–195 (1985).

K. Nagasaka and F. Hashimoto, ‘Selection of the Cutting Conditions Considering Quality of Chip Disposal’,Bull. Univ. Osaka Prefect 34 (1), pp. 107–117 (1985).

F. Vintner and P. Stanek, ‘A Contribution to Chip Forming Problems in Automated Production’,Strojirenstvi 35 (4), pp. 236–240 (1985) (in Czech).

J. Triesch, ‘Chip Removal and Coolant Filtration on Machine Tools’,Werkstatt Betr 118 (4), pp. 229–230 (Apr. 1985) (in Czech).

D. A. Dornfeld and C. S. Pan, ‘A Study of Continuous/Discontinuous Chip Formation Using Acoustic Emission’,J. Appl. Metalwork 4 (1), pp. 18–29 (July 1985).

‘Control of the Chip in Turning’,Utensil 7 (3), pp. 31–33 (Mar. 1985) (in Italian).

T. Yato, H. Takeyama and R. Murata, ‘Chip Control by Means of Specially Designed Helicoidal Faced Cutting Tool’,J. Mech. Eng. Lab. (Japan) 40 (2), pp. 22–36 (1986) (in Japanese).

C. Rubenstein, P. K. Venuvinod and W. S. Lau, ‘Analysis of Oblique Cutting with Controlled Contact Tools’,Annals of the CIRP 35 (1), pp. 51–54 (1986).

‘Chip Disposal on Machining Centers’,Metalwork Eng. Mark 8 (3), pp. 42–48 (May 1986).

K. Y. Yee, D. S. Blomquist, D. A. Dornfeld and C. S. Pan, ‘Acoustic Emission Chip-Form Monitor for Single-Point Turning’,Proc. 26th Int. MTDR Conf., Manchester, England, pp. 305–311 (Sept. 1986).

V. Rocek, ‘Shapes of Chip Formers and their Application Possibilities’,Strojir Vyroba 34 (5), pp. 377–380 (May 1986) (in Czech).

Y. Hasegawa, S. Hanasaki, J. Fujiwara and T. Wada, ‘Study of Chip Breaker-Development of New Chip Breaker Suitable for Wide Cutting Conditions’, Faculty of Eng., Osaka Univ., Japan (1986).

S. Valcuha and V. Geleta, ‘Methods of Design of Chip Shaper for Interchangeable Cutting Tips’,Strojirenstvi 37 (1), pp. 34–39 (1987) (in Czech).

H. T. Young, P. Mathew and P. L. B. Oxley, ‘Allowing for Nose Radius Effects in Predicting the Chip Flow Direction and Cutting Forces in Bar Turning’,Proc. Inst. Mech. Engrs. 201 (C3), pp. 213–226 (1987).

I. S. Jawahir and P. L. B. Oxley, ‘New Developments in Chip Control Research: Moving Towards Chip Breakability Predictions for Unmanned Manufacture’,Proc. Int. Conf. ASME, MI'88, Atlanta, Georgia, USA, April 1988, pp. 311–320.

I. S. Jawahir and P. L. B. Oxley, ‘Efficient Chip Breaking at Reduced Power Consumption —An Experimental Analysis’,Proc. 4th Int. Conf. on Manufacturing Engineering, Brisbane, Australia, May 1988, pp. 97–102.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jawahir, I.S. A survey and future predictions for the use of chip breaking in unmanned systems. Int J Adv Manuf Technol 3, 87–104 (1988). https://doi.org/10.1007/BF02601836

Issue Date:

DOI: https://doi.org/10.1007/BF02601836