Abstract

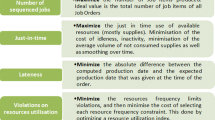

The loading problem in flexible manufacturing systems warrants the consideration of multiple objectives for effective use of its capabilities. The problem is formulated as a multicriterion programming model. The min-max approach is used to find the solution. The results of a particular example are presented to illustrate the application of the model.

Similar content being viewed by others

References

A. Kusiak, ‘Flexible manufacturing systems: a structural approach’,International Journal of Production Research,23, (6), pp. 1057–1073 (1985).

K. E. Stecke, ‘Production planning problems for flexible manufacturing systems’, Ph.D. dissertation, Purdue University, West Lafayette (1981).

S. Y. Nof, M. M. Barash and J. J. Solberg, ‘Operational control of item flow in versatile manufacturing systems’,International Journal of Production Research,17, (5), pp. 479–489 (1979).

K. E. Stecke and J. J. Solberg, ‘Loading and control policies for a flexible manufacturing system,’International Journal of Production Research,19 (5), pp 481–490 (1981).

K. Shanker and Y. J. Tzen, ‘A loading and dispatching problem in a random flexible manufacturing system’,International Journal of Production Research,23 (3), pp. 579–595 (1985).

P. J. O'Grady and U. Menon, ‘A multiple criteria approach for production planning of automated manufacturing’,Engineering Optimisation,8 (2), pp. 161–175 (1985).

K. E. Stecke, ‘Formulation and solution of nonlinear integer production planning problems for flexible manufacturing systems’,Management Science,29 (3), pp. 273–288 (1983).

H. Jutler, ‘--Liniejnaja modiel z nieskalkimi celevymi funkejami (Linear model with several objective function)’,Ekonomika i Matematiceckije Metody,3 (3), pp. 397–406 (1967).

A. Osyczka,Multicriteria Optimization in Engineering, Ellis Horwood, Chichester, (1984).

G. Fandel and T. Gal,The Min-Max Approach in Multiple Criteria Deciston Making: Theory and Application, Springer-Verlag, New York (1980).

K. E. Stecke and J. J. Solberg, ‘The optimality of unbalancing both workloads and machine group sizes in closed queueing networks of multi server queues’,Operations Research 33 (4), pp. 882–910 (1985).

J. J. Solberg, ‘CAN-Q User's Guide’, Repert No. 9, NSF Grant No. APR 74 15256, School of Industrial Engineering, Purdue University, West Lafayette (1980).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kumar, P., Singh, N. & Tewari, N.K. Multicriterion analysis of the loading problem in flexible manufacturing systems using Min-Max approach. Int J Adv Manuf Technol 2, 13–20 (1987). https://doi.org/10.1007/BF02601473

Issue Date:

DOI: https://doi.org/10.1007/BF02601473